Power on Demand: Build a Portable Charging Station!

A conveyable charging station is among the most essential items of apparatus for anybody who flies electrical plane, and whereas there are some good industrial models available on the market, I choose one thing extra compact and designed to my specs. Here, we’ll cowl a easy process for putting in an AC energy provide, a charger, and parallel boards in a journey case. While we’ll cowl particular decisions, this basic process may be tailored to quite a lot of {hardware}.

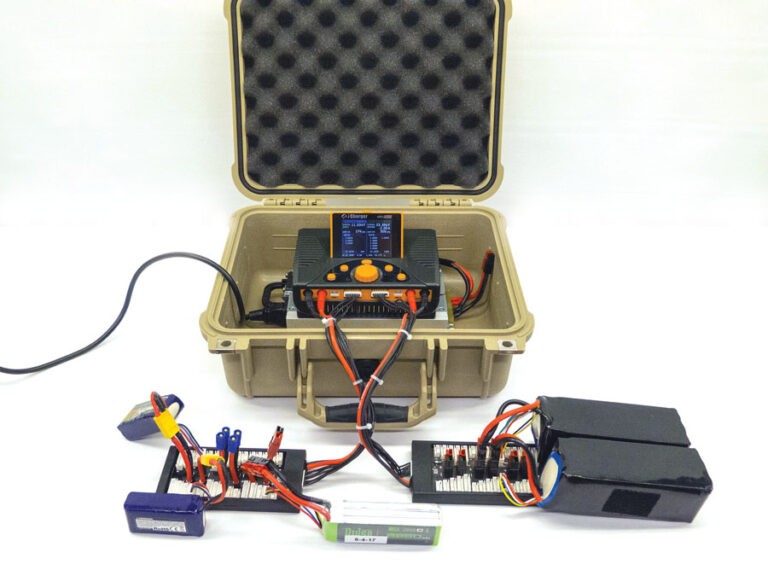

A superb charging station makes flying way more handy. This system can cost as much as 12 batteries concurrently whereas offering twin shows of cost standing and inner resistance.

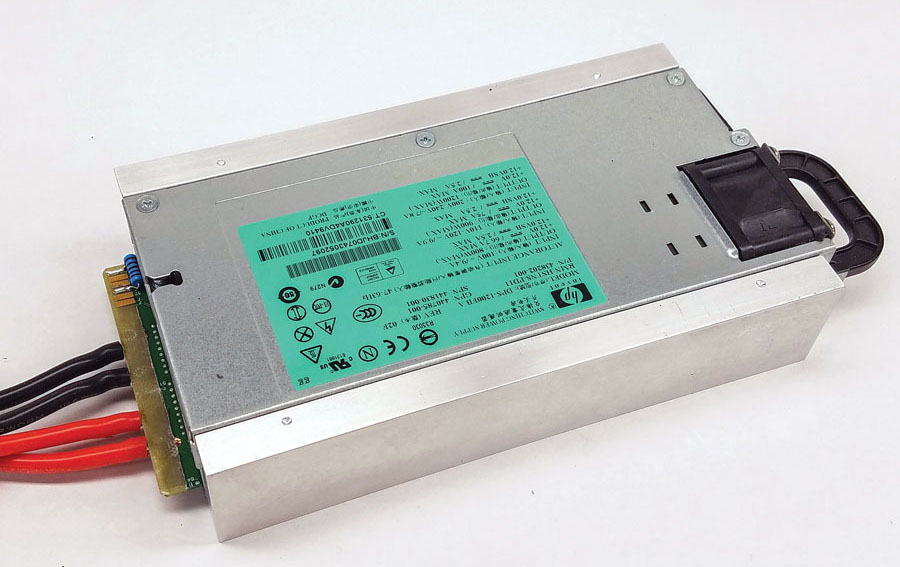

There are many energy provides focused particularly for electrical fliers, however I choose to make use of the extensively obtainable Hewlett-Packard DPS-1200FB, which is designed for rack servers. Despite its compact dimension, the DPS-1200 places out 900 watts on 120-volt AC, and yow will discover them on eBay for lower than $50. There are a lot of decisions for circumstances, however I’ve been a fan of Pelican circumstances for years. Pelicans are extraordinarily robust and utterly waterproof, and should you’ve ever left your charger on the subject, you’ll perceive why that’s essential. For this undertaking, I selected an iCharger 406 Duo, which has twin 40-amp outputs and a split-screen show.

ONE

Before assembling your charging station, you first want to switch the DPS-1200FB energy provide in order that it may energy a charger. As proven right here, a 330Ω or 1K resistor have to be soldered throughout terminals 33 and 36 to trick the provision into turning on. Then you must solder heavy energy results in the large energy terminals labeled 51 and 64. I set up two leads simply in case I ever have to energy a second charger.

TWO

Two mounting blocks tie the entire “stack” collectively and mount it within the case.

While wooden 1 x 2-inch would work, I ordered 1/2 x 1 1/2-inch aluminum bar inventory from Metals Depot (metalsdepot.com); aluminum appears to be like extra skilled and supplies a beneficiant warmth sink for the ability provide. I reduce and squared two blocks 7 1/2 inches lengthy.

THREE

To get optimum warmth switch, I mounted the blocks to the ability provide with 3M switch adhesive, though skinny two-sided tape would additionally work. You now have a strong base large sufficient for mounting your charger.

FOUR

The iCharger 406 Duo occurs to have screw bosses molded proper into the case (good contact). I briefly mounted the decrease shell on the ability provide in order that I might mark the outlet places on the aluminum blocks.

FIVE

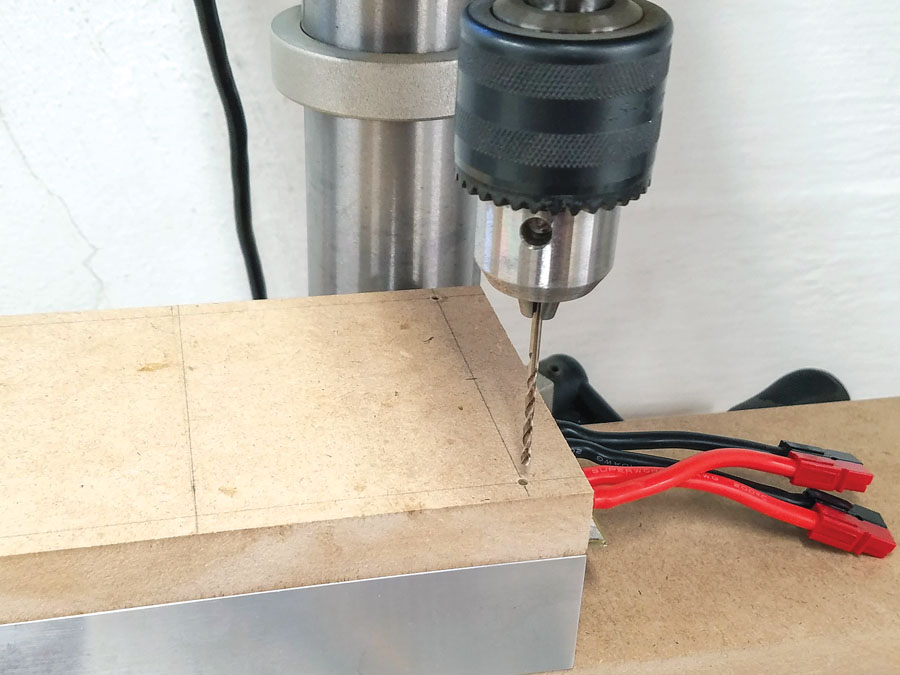

Here, you possibly can see the outlet places marked. Use a drill press to drill 7/64 holes clear by means of the blocks. A drill press is essential as a result of these holes should be completely straight. Use reducing fluid to be sure you don’t break the thin drill.

SIX

Once you’ve drilled all 4 holes, flip the meeting over and counterbore the holes to 7/32, ensuring you cease 1/4 inch earlier than breaking by means of. Again, a drill press is a lot better for doing this precisely.

SEVEN

Next up is drilling the holes for mounting the meeting within the case. The simple means to do that precisely is to make a brief drill information out of MDF (medium-density fiberboard) or scrap lumber. Make positive your gap places received’t intrude with the raised ribs on the underside of your case or the holes you’ve already drilled. For my Pelican 1400 case, 6 3/16 inches was excellent.

EIGHT

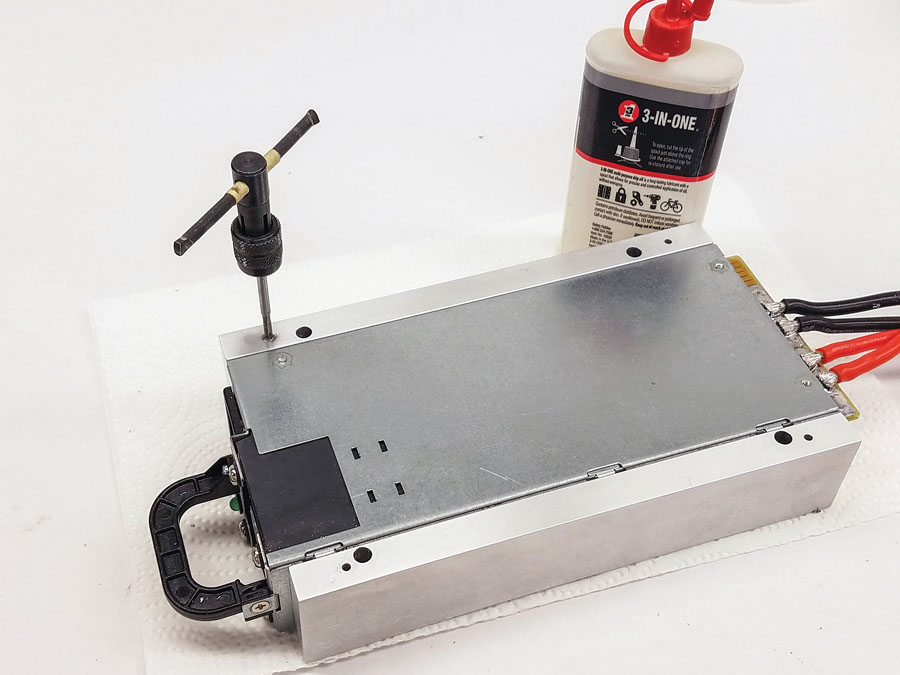

After drilling pilot holes with the suitable drill dimension, it’s time to fastidiously faucet the holes. I used M3 screws, which name for a 2.5mm drill. Take your time with this step, and use a lot of reducing fluid. If you break a faucet, you’ve an issue in your arms.

NINE

With the mounting holes tapped, you now have to drill the holes within the case. Temporarily stick the drill-guide block to the underside of the case with switch adhesive or two-sided tape after which fastidiously drill by means of the holes. Note that I by no means reduce cooling holes in my charger circumstances as I wish to protect the Pelican case’s watertight integrity.

TEN

The ultimate meeting consists of inserting no. 6 x 3/4-inch sheet-metal screws into the counterbored holes and driving them into the screw bosses on the charger. The complete stack is then dropped into the case and secured with M3 x 12mm pan-head screws. Charge leads and steadiness boards or parallel boards may be secured contained in the case with Velcro and pulled out to be used, or you possibly can set up a platform on the entrance of the case for mounting them. The Pelican 1400 supplies room to spare for the ability wire and equipment, corresponding to adapters and your voltage checker. You now have a compact charging station that may present years of service.

BY JIM RYAN