We have the best readers, and we love your unique ways of making building and assembling RC planes easier. Here are a few of our favorites; bet you’ll use at least one on your next project! (Have a tip you’d like to share? Send it to MAN@airage.com and you could win a free subscription to The Hangar, our membership-only site!)

CLEAR GLUE TO THE RESCUE

Sometimes a hard landing means you’ll need to repair your indoor flier. For models that have plastic struts and other fine attachment points, Bob Smith Industries’ Foam-Cure is an ideal repair adhesive. Squeeze out some glue on a notepad, use a toothpick to apply a very small amount to the affected parts, and tape them together for about 10 minutes. The adhesive dries clear and flexible—and it is foam-safe.

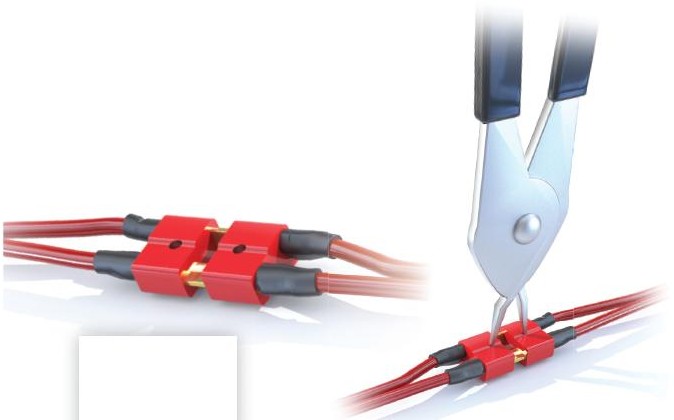

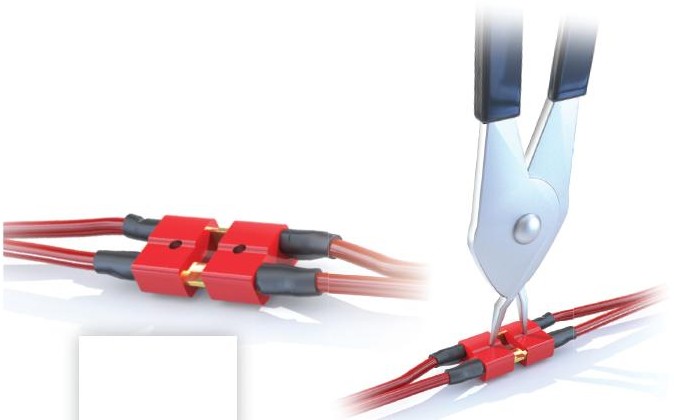

EASY DEANS

Many folks use Deans connectors with their electric planes but find them difficult to disconnect. A small reversible pair of snap-ring pliers can do the trick. Drill a small hole in each half of the Deans connector so that the pliers fit. Use caution, and do not drill all the way through the connectors—just deep enough for the points of the pliers to do their job.

CHEAP RACK

Need a way to hang up model parts but don’t want to spend a lot of money? You can find a folding metal clothes rack at a local home-supply store. It cost less than $20 and is strong, compact, and perfect for drying painted plane parts.

TOOLBOX SECURITY

Avoid dumping your tools all over the place by getting in the habit of attaching a small carabiner clip to the locking hole on your toolbox. This is especially helpful as the toolbox ages and the plastic latch doesn’t hold as well.