As grasp scale modeler Dave Platt has mentioned, “A scale model is never truly finished–you simply stop working in it.” I first check flew my Sopwith Camel with my Zenoah G38 engine totally uncovered in that huge radial cowling. So, to assist costume it up, I’ve begun to put in a dummy rotary engine. I hope you discover the methods concerned attention-grabbing as they can be utilized on any comparable spherical nosed airplane you may be constructing.

Starting level

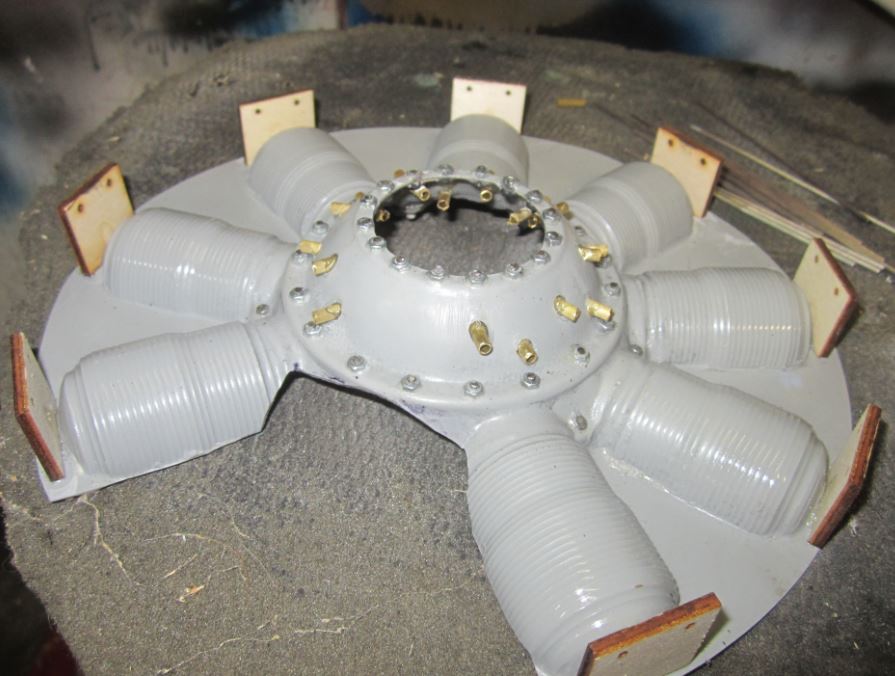

Balsa USA is a superb supply for all issues WW1 they usually have been providing good molded fiberglass dummy engines for a very long time. I picked up a 9-cylinder molding on the latest Rhinebeck Jamboree and wasted no time in getting it detailed out and able to add the Camel’s engine compartment.

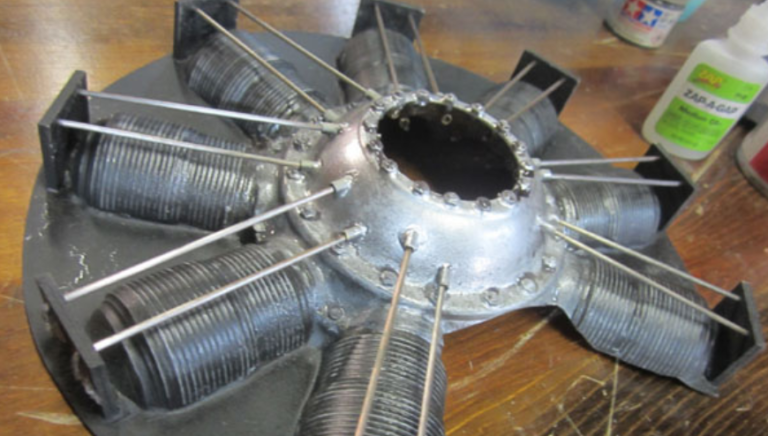

Nicely molded from a number of layers of fiberglass fabric, the BUSA molding is properly detailed. You would spend much more time making an attempt to make your personal. This is an older photograph, the one I simply picked up has a pleasant gel coat end on the entrance.

The very first thing to do with any molded fiberglass half is to make use of a grinding wheel and a Moto-tool and take away any sharp edges or areas starved of resin. After this, throw it within the kitchen sink and scrub it with dish washing detergent so you may take away any left over parting agent that may nonetheless be on the surfaces.

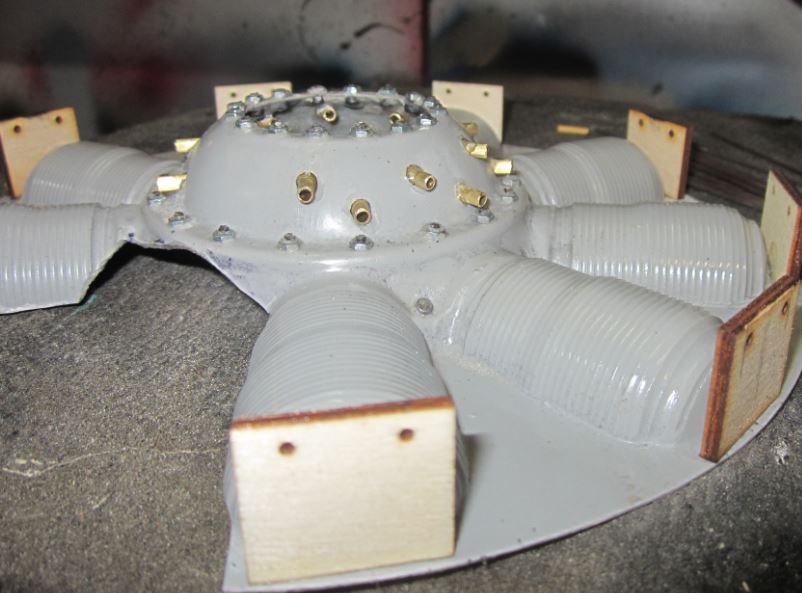

Here you see the open finish of the cowling, it is very important use a molded engine that can match correctly. The 1/4-scale BUSA rotary engine is 7 3/4 inches in diameter, an ideal match.

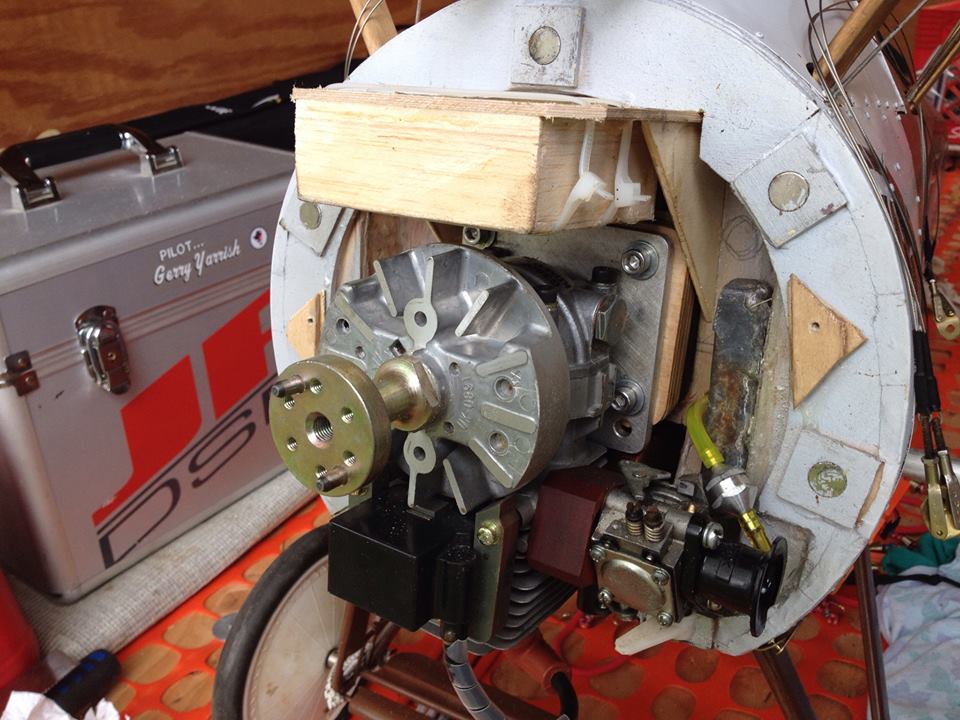

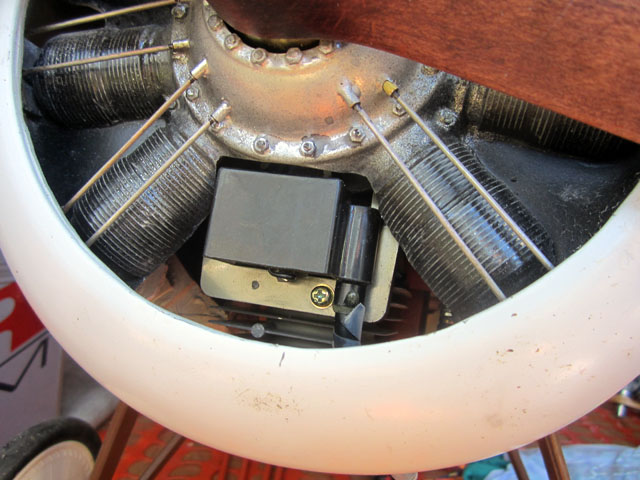

With the cowling eliminated you’ll discover I put in a ballast field crammed with lead shot and resin proper over the engine. I made it’s dimensions with the usage of a dummy engine in thoughts.

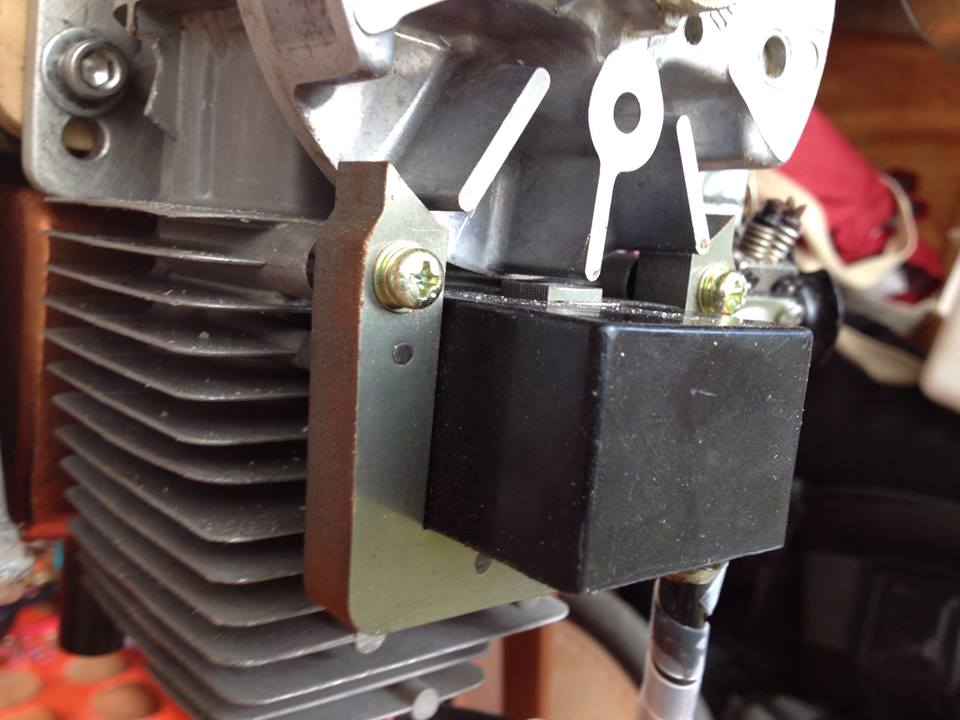

Here’s the entrance finish of the G38 with it flywheel and magnet for the magneto ignition displaying proudly in entrance of the cylinder head. The engine is put in upside-down with the cylinder and muffler each pointing downward. The very first thing to do is to open up the molded engine to clear the ignition block. But extra importantly, the opening can be for cooling airflow to enter the engine compartment.

Making the opening is simple with a cutoff disc and a Dremel. I merely eliminated one of many cylinders and opened up the world between the opposite cylinders as proven right here. Also, the middle opening for the crankcase, needs to be large enough to suit over the G-38’s propeller hub.

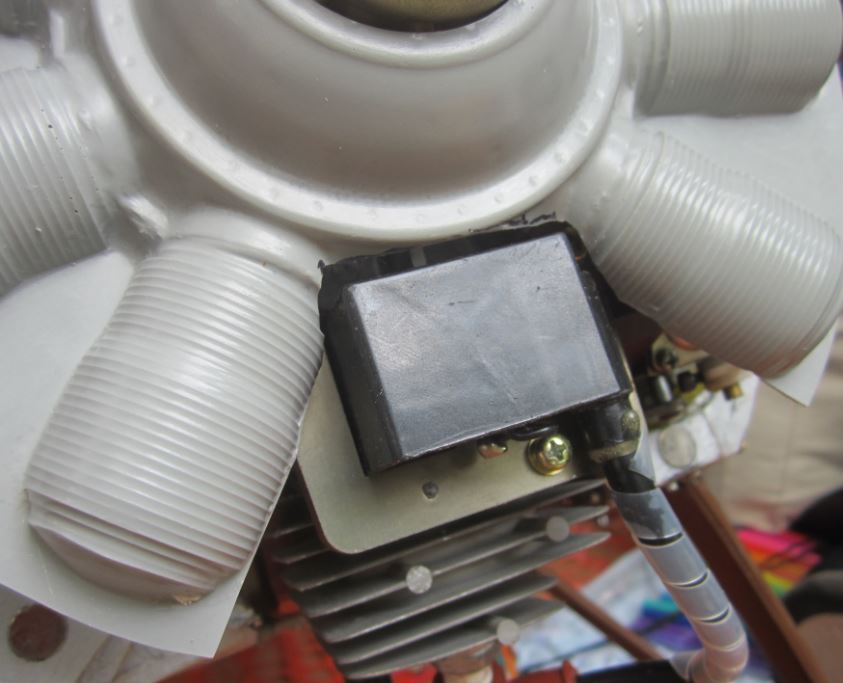

Here I’m check becoming the molding over the G-38. The opening ought to present about 1/8 inch of clearance throughout so vibration gained’t trigger any chaffing of elements. You may also see that cylinder is correct within the line of fireplace for airflow.

So the molding matches properly centered over the G38 whereas contacting the entrance of the ballast field. Another advantage of the field construction is that it helps channel airflow down towards and across the engine and never up within the empty area concerning the engine.

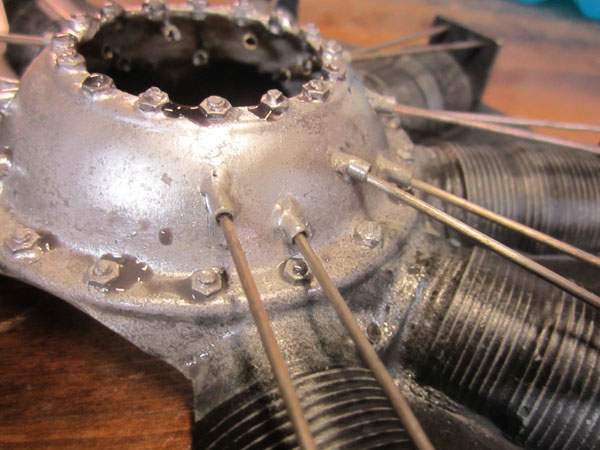

Before portray, I drilled holes and added nuts and screws so as to add element to the engine case. Also, I drilled offset holes within the engine case for the bushing (from quick sections of brass tubes), for the pushrods which might be added later. Medium and Thick ZAP CA glue is used all through. Be gentle with the kicker as it will probably trigger the glue to foam up, which won’t assist the end.

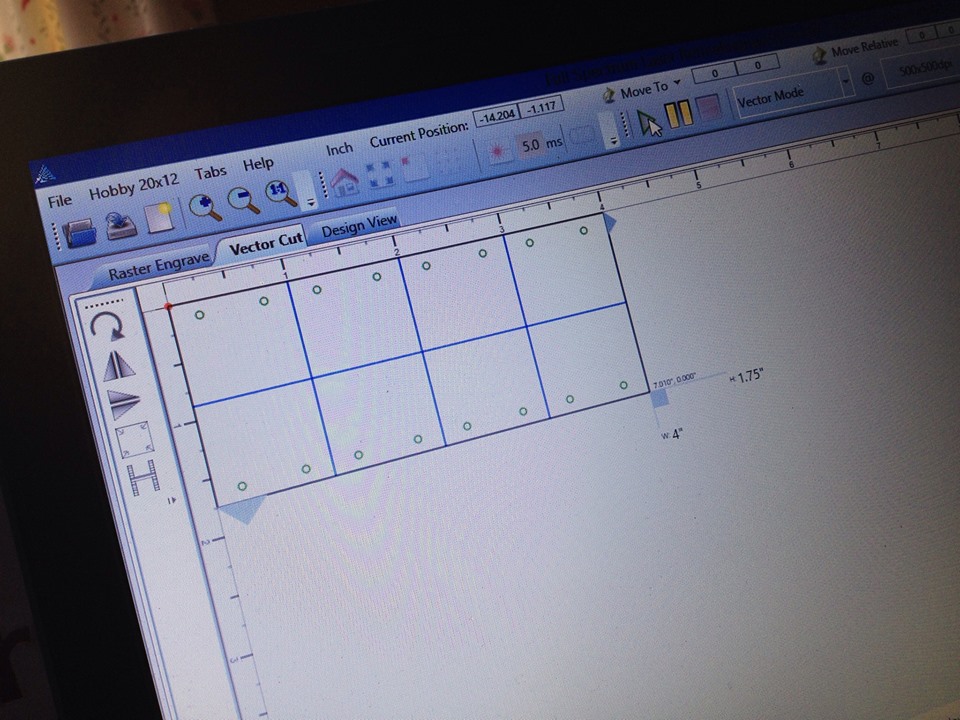

You may also have observed the lite-ply information/helps I glued to the engine molding. These have 1/16 inch holes in them set on the correct spacing to carry the pushrod wires. Here is the straightforward minimize job loaded into my laser cutter.

Using my 40W Full Spectrum Laser Hobby Laser I used to be in a position to import some easy CAD drawing and minimize out the eight are required for the dummy engine. You can see the lite-ply information plates intimately right here under.

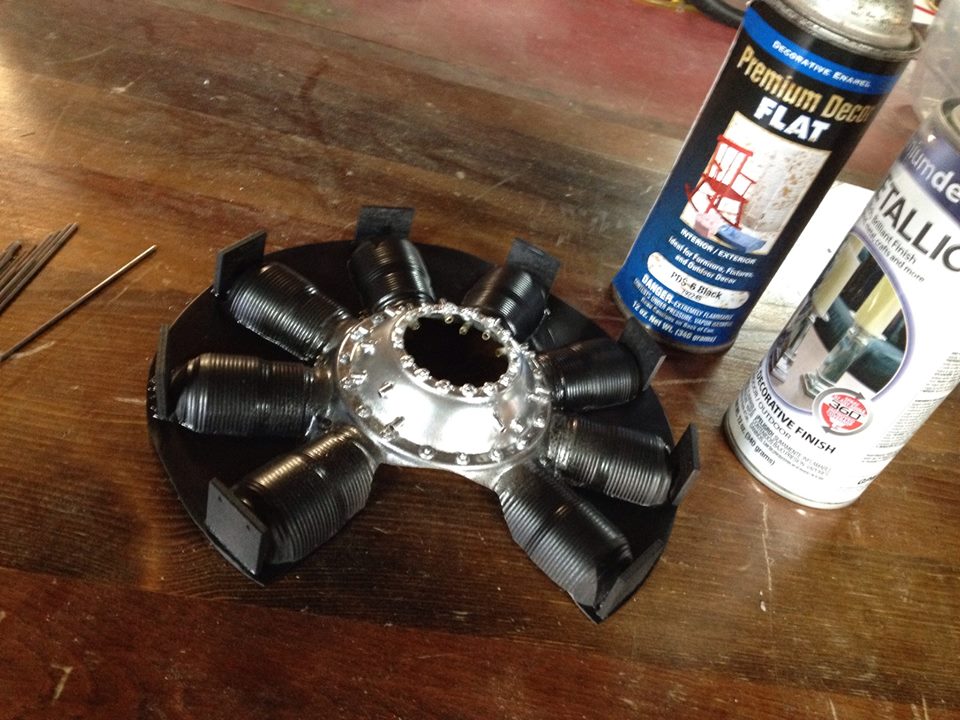

Painting

To start the paint job, I begin with a coat of metallic silver from Décor. This paint is quick drying and it provides an actual metallic nearly chrome look to the half. I like utilizing this vivid coat as the primary layer which I’ll construct the weathering coats onto later within the course of.

The paint actually makes all of the bits and items come collectively for a scale look. The 16 pushrods are constituted of items of 1/16 inch welding wire.

So right here the cylinders, and the again webbing have been spray painted flat black. I’ve discovered that there isn’t any have to rigorously masks off the engine case whereas spraying the cylinders. Again right here I take advantage of Decor spray paint which dries in a short time and is gasoline proof when dry.

As you may see, there’s a slight quantity of over spray on the perimeters of the crankcase, and that’s what we wish. Additional detailing and weathering might be added to the engine to assist deliver out the finer element and general realism a scale mannequin requires.

The subsequent step is so as to add the pushrods. For the Sopwith Camel, I need a extra “used” look.

Here above, we have now the 16 pushrod wires for the rotary engine. I used 1/16 inch welding wire and sanded them clean and clear. They has a pure steel end so no portray is required. I additionally bent one finish 90 levels. The size is about 1/4 inch.

Before putting in the pushrods, I took some 320 grit sandpaper and glued it to some wooden to kind sanding sticks. A large one for the highest of the cylinder and a slim one for the bottom. As you may see, by rigorously sanding away the black paint, you expose the underlying silver and grey colours. This provides depth and kills a number of the shine of the black paint.

As with the whole lot else about scale modeling and weathering, it takes a refined contact. Don’t get heavy handed as you’ll solely make the silver traces (tops of the cooling fins), wider.

After sanding the fins, I am going across the engine case and apply a really skinny layer of watered down acrylic black to all the main points. When dry, this black will being out the floor particulars.

Here you see two of the pushrod wires inserted into the wooden information plate and inserted into the brass bushing tubes on the crankcase. A bit ZAP will maintain them in place. These prime plates might be coated over by the lip of the engine cowling and never seen.

Here all of the pushrods are in place. They are glued on the prime bent ends in addition to contained in the bushing tubes from the within of the engine molding.

Next I mist a really gentle coat of sunshine grey over the chrome silver base colour of the crankcase and let dry. I additionally use a skinny brush and add a grey wash to flat areas and in corners the place the actual full-size engine would collect mud and oil residue.

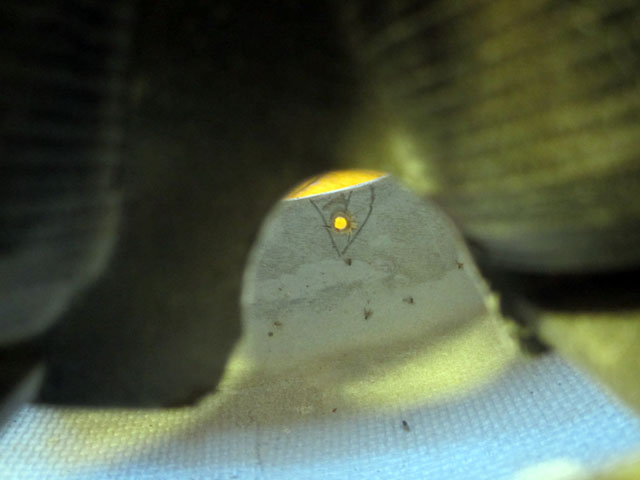

Here you see the grey and black wash nonetheless puddled round a number of the nuts and screws across the engine and the bottom of the cylinders. Now let it dry. You can pace the method with a warmth gun, however I discover that letting the washes evaporate naturally produces the perfect trying staining.

The over all mission took solely about 10 hours and unfold over a number of days, that’s no time in any respect. I lastly determined to connect the molded engine to the within of the engine cowling. This is the everyday method to affixing it to a mannequin, however if in case you have the room, you may also set up standoffs to the firewall across the G38 and fasten the dummy rotary that manner. Here’s how I did it.

You’ll discover the wooden information plates I put in above every cylinder. These each assist the pushrod wire ends and, give glorious attachment factors for the molding to be glued to the within of the engine cowling.

After sanding the paint off of the perimeters of the information plates, set the dummy engine in place over the mannequin’s actual engine and then you definately reattach the engine cowling. Make positive the dummy engine is centered across the prop hub and that nothing is available in contact with the G38 when the propeller shaft is turned. Now tack glue a few the information plates to the within of the cowling utilizing Thick Zap and kicker. Remember, earlier than making use of any glue, it is essential to wash off the internal floor of the cowling to make sure a powerful glue bond. I take advantage of MEK to take away all of the paint and primer from the internal floor of the fiberglass cowling.

After the glue units, tack glue a pair extra plates to the within of the cowling. Once you have got three or 4 plates glued in place, you may take away the cowling.

Here’s a detailed up of one of many plates glued to the cowling. Finish gluing the remainder of the information plates in place being positive to construct up a powerful fillet across the information plates.

After all of the attachment factors have been secured, be sure you make some openings within the webs between the cylinders. These are to get to any screws or different attachment factors for securing your engine cowling in place.

All you want is a gap massive sufficient to suit a screwdriver . With my magnetically secured cowling, I additionally put in two screws to stop the cowling from rotating as a result of engine vibration. The screws undergo the rear plywood cowling ring and thread into onerous factors within the entrance of the firewall.

Here you see the bottom of the dummy engine. Notice that there’s loads of area across the dummy engine for airflow to chill the engine. Most of the airflow might be via the massive opening simply in entrance of the cylinder. Also if there is a hole between the cowling and any of the plates, (as proven right here to the proper), add a scrap of lite ply to fill within the area. Use loads of Zap and kicker.

Reinstall the engine cowling and verify the clearances across the mannequin’s engine. Try to have no less than 1/8 inch throughout. When the whole lot traces up correctly, take away the engine yet one more time and provides it a number of gentle coats of honey coloured clear Urethane spray end. This will seal the wooden information plates and coat the pushrods so that they don’t corrode. Also the colour give the engine a semi moist appear to be it simply ran and is roofed with caster oil.

So, that’s it! The molded fiberglass dummy rotary engine from Balsa USA is a wonderful start line for any spherical nostril airplane. It actually is quite a bit much less work than scratch constructing your personal WW I cover-up. After a few flight, verify the clearances between the size engine and the prop hub. If something is rubbing, use a Dremel Moto-Tool and grind away any interference areas to extend the clearance. Also take note of how your engine runs. If it appears to be working hotter than earlier than, modify the carb, to richen the highest finish just a little. And recheck the idle transition. Have enjoyable!

TEXT & PHOTOS BY GERRY YARRISH