HOW TO: MOUNT AILERON SERVOS — Flush Neat and Strong

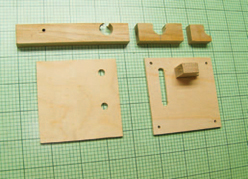

My newest sport-scale mannequin, a 1/5-scale Sopwith Triplane, has a fairly skinny wing (although it’s thicker than scale at 1 inch on the aileron servo). A lowprofile servo, reminiscent of Airtronics 94921 or Hitec 77BB, would match with the shaft vertical, however I had customary ones available, so I went with them. I made an 1/8-inch-thick and a couple of 7/8-inch-wide plywood plate to suit between the ribs on the servo location and a couple of 1/2 inches lengthy to go between the primary spar and aileron spar. I glued a 3/8-inch-wide strip of 1/4-inch-thick plywood to the within of the ribs in order that I may mount the plate. Use a chunk of scrap out of 1/8-inch-thick plywood as a information to inset the mounts in order that the servo plate is flush with the skin floor of the wing. Position the servo on the plate, and mark the place the output arm will protrude. Keep the skin fringe of the slot 1/2 inch in from the sting of the plate in order that nothing will intervene when the plate is in place on the mounting strip. Drill 1/4-inch-diameter holes at every finish of the slot, and minimize between the holes with a hand-coping noticed or energy jigsaw. The Dremel jigsaw that I’ve had for years works properly.

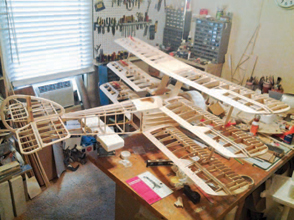

Building the Sopwith Triplane means that you’ve got six aileron installations. I set up my two aileron servos within the backside wing after which drive the 4 others about them with slave rods. Keeping the servos within the backside wing eliminates having to run servo leads up the cabane struts to the highest wing.

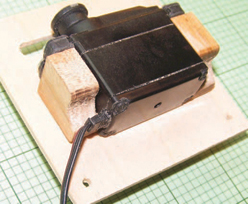

You can mount the servos to the plates with aluminum angle or 3/8-inch-thick hardwood blocks. Because I all the time have maple available and a small, 8-inch-diameter-blade desk noticed, I made up some wooden blocks as proven within the picture. Drill a 1/8-inch pilot gap and a 1/2-inch-diameter gap at one fringe of the strip. The pilot gap makes it simpler to drill from each side, lowering the splintered breakout. Wrap the servo with three layers of masking tape to create an area across the servo after it has been mounted.

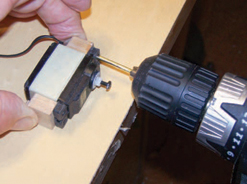

Place the servo and mounting blocks on a flat floor, and maintain them in place. Spot switch the servo holes to the blocks. I’ve made a easy instrument for doing this, and it really works each time. It’s merely a 3/32-inch-diameter drill inside a chunk of 1/8-inch-outside-diameter brass tube. Cut the tube 1/8 inch shorter than the drill. Insert the reducing tip of the drill 1/2 inch into the tube. Coat the uncovered drill with 5-minute epoxy, and push it via the tube till 3/32 inch of the tip is uncovered (it needs to be freed from epoxy). Let it remedy.

The 1/8-inch tube gained’t match via a servo-mount eyelet, so its diameter must be diminished. Place the drill/tube meeting in an electrical drill, and with it working, use a file to cut back the skin diameter till it should match via the eyelet. I take advantage of a 3/32-inch-diameter drill for a no. 4-40 faucet. This is a little bit smaller than the 0.099 inch my drill index requires, but it surely creates a deeper thread within the wooden.

Take the tape off the servo, and assemble the blocks to the servos. For ailerons, you should definitely make a proper and left; the flaps would be the identical.

AILERONS 101

I bear in mind again within the early days of RC when aileron servos (or ought to I say “servo!”?) had been mounted within the heart of the wing. Two pushrods operated strip ailerons, or they went to the outer-wing panels to a bellcrank and pushrod to barn-door ailerons. This was just about the usual set up. With bigger fashions and comparatively cheap servos, a servo on every management floor is now frequent. This is a greater system, providing a number of benefits. The most blatant is redundancy: If one servo fails, aside from driving exhausting to at least one aspect, you may have a great likelihood of retaining management. Another necessary benefit is that, by utilizing two channels, one on every aileron servo, you possibly can arrange exact centering and journey.

Here are the components you want: the mounting rails, servo attachment blocks, and hatch covers. The cowl to the left has two holes in it forming the ends of the slots. Remove the fabric between the holes, and sand it easy.

With the blocks connected to the servo with double-sided tape, I flippantly press into the blocks with the drill bit that’s centered within the grommet with the brass tube.

Use a size of brass tube and a drill bit, as proven, to precisely mark the place of the screw holes on the mounting blocks.

For correct gap alignment, I end drilling out the holes utilizing my drill press, with the blocks held in a vise.

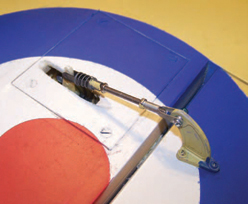

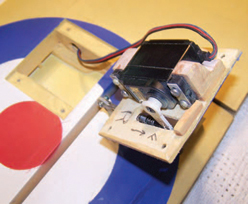

Here is the completed servo set up on the hatch cowl. The blocks are glued to the hatch with Z-Poxy in order that the servo arm is centered within the slot.

Here the hatch cowl is in place in my Sopwith Triplane wing.

Notice the notch within the block. This permits the servo result in clear the block with out interference.

With the hatch cowl eliminated, you possibly can see the attachment rails, that are glued to the wing ribs.

There is one other necessary motive for utilizing two channels, and that’s to permit simple setup for differential ailerons. I really feel that this is applicable to coach, sport, and particularly scale fashions. I’m stunned by what number of modelers should not conscious of the significance of differential aileron journey, the place the journey of the upward-moving aileron is greater than the downward-moving aileron. The downward aileron will trigger extra drag on the unsuitable wing (outdoors the flip), inflicting antagonistic yaw. Starting with 50% right down to full up will mechanically enable for yaw within the correct path, making scalelike, coordinated turns. Don’t be afraid to cut back it much more. As little as 30% down will not be unreasonable. Coupling some rudder in a flip provides to the realism. If you don’t mechanically enter rudder in a flip (some pilots do, however most don’t), then let your transmitter apply it. Most late-model transmitters have aileron-to-rudder coupling. Start with about 20%.

An training in differential ailerons got here my means just a few years in the past when my good associates Bob Walker (of Robart fame) and Bill Samson determined to enlarge my scale 72-inch-span Windex 1200C powered glider to 96 inches and add ailerons. I printed the 72-inch model in Model Airplane News (plan X0801A) within the August 2001 concern. With no ailerons and powered by a Speed 400, it flew nice. Bill completed his and actually didn’t like the way in which it flew; it simply wasn’t what he anticipated. Bob was into another initiatives on the time, so gave his framed-up Windex to me to complete. The backside line is that I completed it and wasn’t very proud of it, both. It was good in pitch, truthful in yaw and rudder, and by no means good in roll. I elevated the dihedral a little bit, and that made the rudder management higher. Some differential was in place once I put in the offset servo arms and management horns, however this was too little for the lengthy, high-aspect-ratio wing. Because I used to be utilizing a 4-channel radio and couldn’t electronically enhance the differential, I elevated the offset within the controls (rather a lot) to provide me 7/16 inch up and 1/8 inch down. This, plus a 25% aileron-to-rudder combine, made the Windex a nice mannequin to fly. Control-surface adjusting pays off!

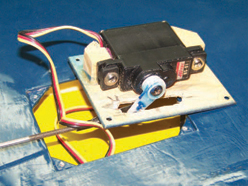

Here is the aileron servo set up in my Windex glider. The servo is smaller than on the Sopwith Triplane, however the approach is identical.

The identical association is utilized in my big Spitfire fighter. Mounting the servos internally additionally cleans up the look of your fashions.

The enlarged Windex has Hitec HS-81 customary microservos on the ailerons. Just underneath 1/2 inch thick, they simply match into the simply over 1/2-inch-high space on the servo location. The servos are screwed to a few small maple blocks epoxied to the 1/16-inch-thick plywood cowl. If I used to be doing this once more for this utility, I might glue the servo to the plywood cowl with Pacer Zap Goo as a result of the vibration stage is so low. Wrap the servo with a layer of masking tape to make cleanup simpler whether it is eliminated. The Zap Goo will maintain the servo securely in place. I wouldn’t do that with something however a small electrical or electric-powered glider mannequin.

Most of my giant-scale fashions have wings which can be thick sufficient to mount the servos with the output shaft vertical, and this makes servo and control-arm entry simple. Of course, the arm and pushrod are uncovered and may be a static rating downgrade in competitors!

Here is the Sopwith Camel on its first check flight. It performs properly and is ready up with differential aileron management response to counter antagonistic yaw.

Nick Ziroli Sr.