Fast Foam Fixes: Easy repairs to save your molded ARF

When it involves flying RC airplanes, the probabilities are that your stunning molded ARF goes to endure some injury. There’s no motive, nevertheless, to trash your crash. With a bit of effort and time, you will get again into the air, and you can also avoid wasting bucks by repairing your bent hen as a substitute of shopping for new elements or a wholly new airplane.

What’s Needed

The provides wanted for any mannequin restore are a interest knife with sharp substitute blades, some masking tape, a sanding bar with medium sandpaper (100 to 150 grit), and a few wonderful 220-grit sandpaper. The glue wanted is 15-minute two-part epoxy, foam-safe CA adhesive, and foam-safe accelerator. Denatured alcohol is nice for cleansing the floor of the froth and for cleansing up extra epoxy from repairs. We used an assortment of glue, together with these by Bob Smith Industries and Flash Adhesives.

Removing Dents

Step 1: The forefront of a foam wing can actually take a beating, however dents are actually solely beauty points. If you may have a minor dent, merely apply a moist paper towel to it and warmth with a protecting iron. Most of the time, the steam will increase the froth and your dent will disappear.

Step 2: If the dent is extra pronounced, you may shortly minimize away a piece of the broken materials with a razor noticed and glue in some new foam.

Step 3: Cut some new foam to size, and glue it in place with foam-safe CA. The finest manner to do that is to chop the froth a bit oversize, and spray foam-safe accelerator to the brand new materials. Apply the CA glue to the cutout space, and insert the restore piece. Hold it in place till the glue units. Use your noticed to take away many of the undesirable materials, then use a sanding block to easy the substitute piece.

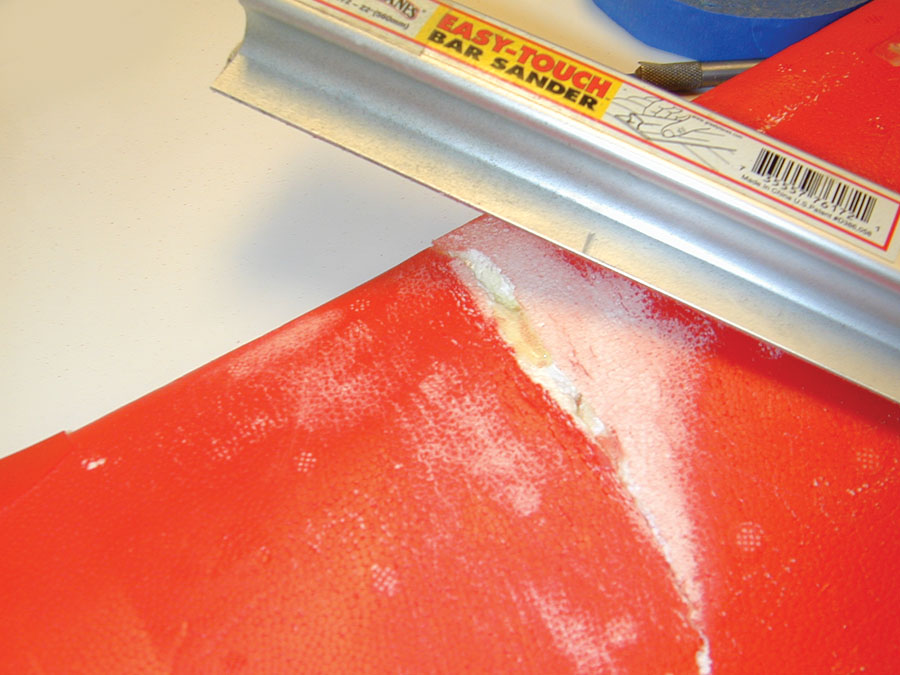

Step 4: Apply a bit of interest filler across the edges to fill in any gaps (Hobbico HobbyLite Filler is nice for this).

Step 5: Once the filler has dried, use wonderful sandpaper to easy the restore. If it is advisable, apply extra filler across the restore space to feather out the restore space.

Step 6: Apply some matching foam-safe paint to finish the modern wing restore. The hardest a part of this restore actually is discovering matching paint. Usually, the directions that include your airplane will name out the colours used. If not, go to the interest store and take a look at the Master Modeler and Tamiya manufacturers of acrylic foam-safe paints. You’ll have the ability to match the colour chips after which lighten or darken the colours barely to match. In actual life, warbird repairs seldom matched the remainder of the airframe, so welcome to scale weathering!

Mending Broken Wings

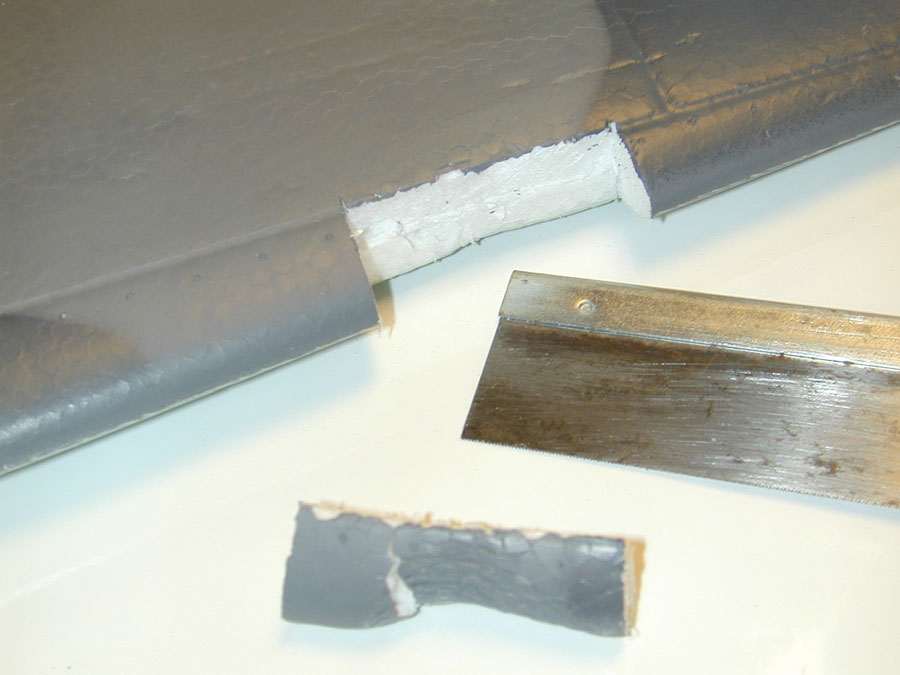

Step 1: In excessive circumstances, you would possibly break a foam wing in two (or extra!) items. An incredible trait of froth is that it’s normally very straightforward to piece again collectively. Mix up a small batch of 15-minute epoxy on a plastic can lid. Run two or three lengths of every half as proven after which combine collectively.

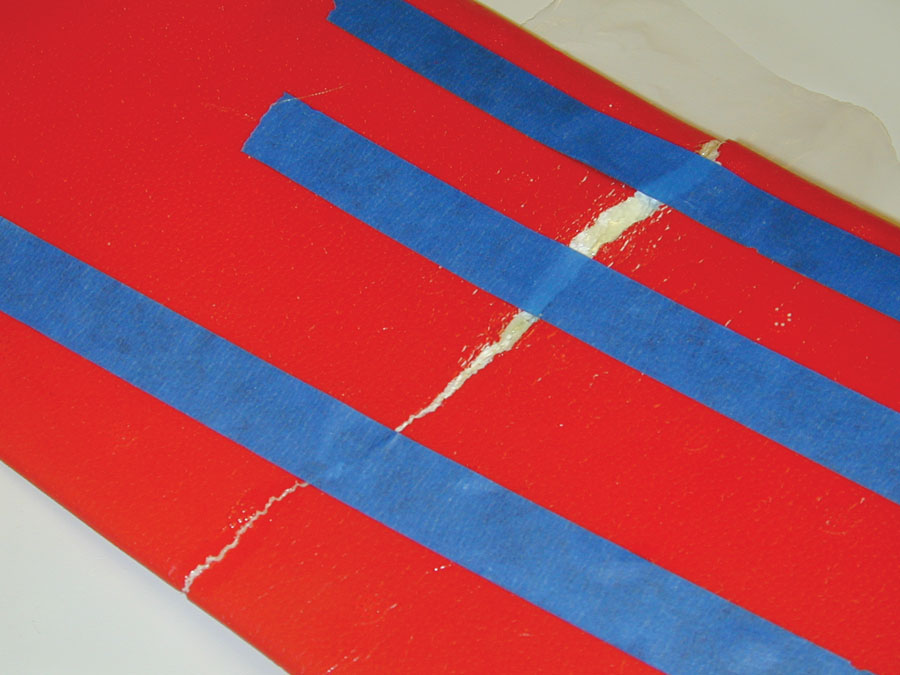

Step 2: Place some waxed paper or meals wrap below the wing items after which apply simply sufficient combined epoxy to cowl the uncovered ends of the break. Use some masking tape to carry the elements collectively whereas they relaxation flat towards your work floor. Be positive to wipe away any extra epoxy that oozes from the restore utilizing a paper towel and a few

Step 3: After the epoxy has set, take away the tape. Using a sanding bar, easy out the restore space.

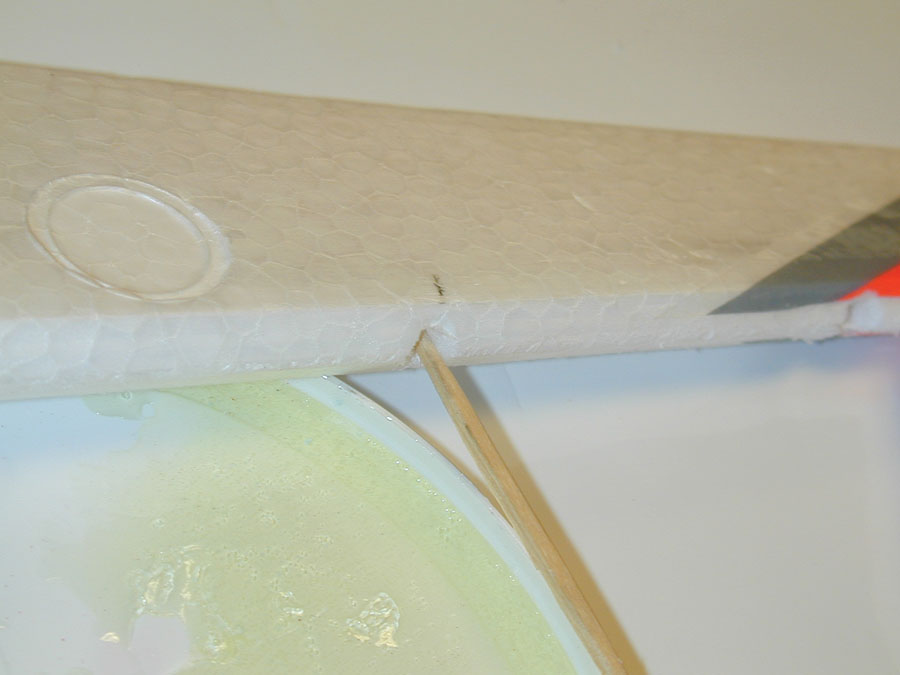

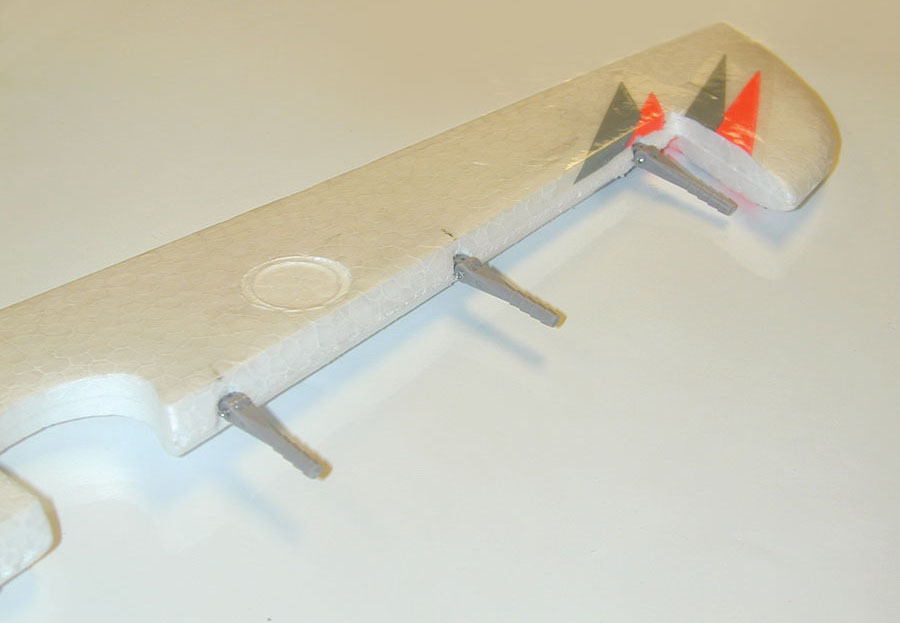

Step 4: If your wing is greater than 36 inches in span, use a chunk of skinny plywood that’s 4 to six inches lengthy and 1/2 inch broad as an inner brace. Using a interest knife and a razor noticed, minimize a straight line all through the wing, as proven. Test-fit the plywood, then apply foam-safe CA and insert it into the wing. Apply some accelerator, and let the glue set.

Step 5: After the glue units, apply mannequin filler to the restore and let the filler dry.

Step 6: Using wonderful sandpaper, sand the filler easy and flush with the remainder of the wing floor.

Step 7: Apply matching foam-safe paint, and let it dry. The restore is full, however it’s also possible to apply some decals over the restore space, for those who like, to fully cowl the mended space.

Repairing Foam Hinges

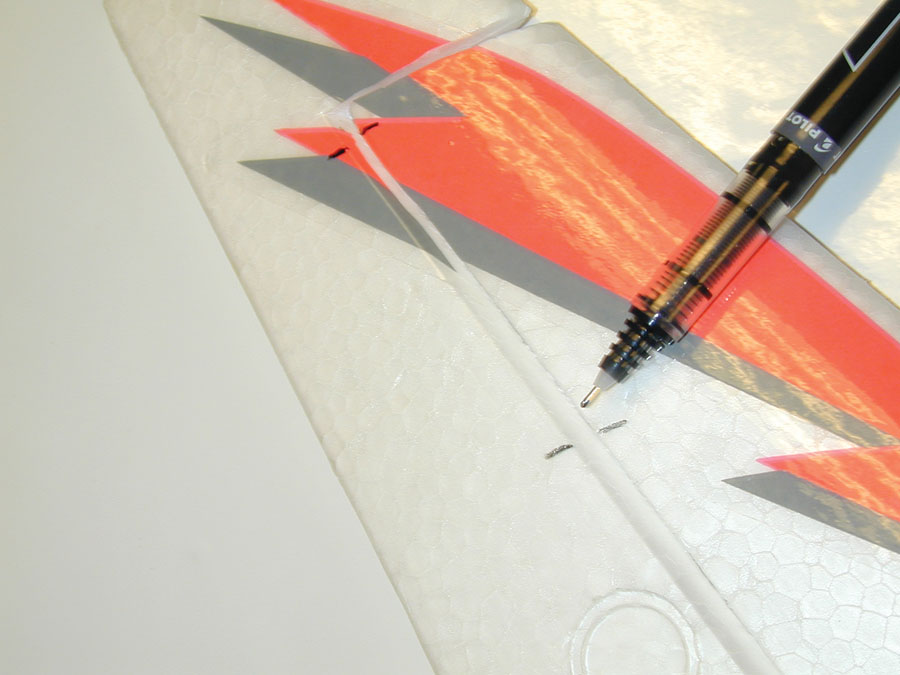

Step 1: It just isn’t attainable to restore a live-foam hinge, the place the hinge is molded in as a part of the management floor. It is finest to put in new hinges within the broken surfaces. Before eradicating the floor, mark the areas for the brand new hinges. For this rudder, three 1/8-inch Robart Hinge Points can be put in.

Step 2: After marking the hinge areas, take a pointy interest knife and slice by the molded hinge to separate the rudder from the fin. Use some sandpaper to easy the mating surfaces.

Step 3: Sharpen the tip of a 1/8-inch brass tube, and use it as a drill to supply the holes for the Hinge Points. This produces a lot neater holes than a wooden drill bit.

Step 4: Mix up some 15-minute epoxy, and use a toothpick to use the adhesive into every of the holes within the rudder.

Step 5: Insert the Hinge Points into the holes, and put aside till the epoxy cures. Make positive that no epoxy will get into the pivot pins. If it does, shortly take away the hinge and set up a brand new one. You have about 20 minutes earlier than the epoxy begins to thicken and set.

Step 6: Apply extra glue contained in the holes within the vertical fin, and slide the hinges within the rudder into place. Again, wipe away any adhesive that oozes out of the holes with paper towels and alcohol. Set apart till the epoxy units.

By the Model Airplane News Crew