Easy ARF Scale Makeover: E-flite Stearman

When I noticed the yellow E-flite Stearman from Horizon Hobby, all I may consider was repainting it within the marking of my son Nick Jr.’s full-size Stearman. I knew that, as a result of it was molded out of Z-Foam, this ARF remake can be pretty simple to perform. First off, the wings have the very same shade and markings as Nick’s Stearman, so this is able to save a whole lot of time. I’d usually use an airbrush for a challenge like this, however to avoid wasting masking and prep time, I used a brush to use all of the paint.

To begin, I eliminated the pilot bust for higher entry whereas portray the within entrance of the cockpit. The pilot was held in place with two screws and glue, however after eradicating the screws, it simply broke free. I then ready the windshields. The frames, like the remainder of the fuselage, wanted to be painted mild grey. I lined the surface glass surfaces with masking tape, rubbing the tape tightly into the corners of the glass and frames with a chisel-shaped mixing stick. I then reduce away the surplus tape with a pointy pastime knife to reveal the framework. I then sanded the surface of the frames.

PREP WORK

Before portray the fuselage, I wanted to peel off the numbers and letter decals. I rigorously lifted a nook of every merchandise and peeled it off, pulling it again over itself. Much of the paint got here off with the decals, however the foam wasn’t broken. The yellow coating of paint on this mannequin was fairly heavy, so I sanded all of the surfaces to be painted (besides the wings) with 240-grit moist sandpaper; you could possibly additionally use dry sandpaper used dry. The sandpaper was used to assist clean the areas the place the decals have been. I used 1-inch-wide strips of the sandpaper looped over my fingertip. I didn’t sand via the paint—simply sufficient to uninteresting the floor in order that the brand new paint would have higher adhesion. I didn’t use a sanding block as there have been only a few flat surfaces and I’d have sanded away the molded-in particulars.

When you take away the decals, a whole lot of paint may also come off. Treat these areas with some primer and further paint to fill within the foam floor.

| Tech Tip Before portray or priming a mannequin, examine any questionable paints by making use of somewhat paint on the within of a hatch cowl to see if it should react with the floor. Also, examine the paint adhesion with a bit of masking tape. |

PAINTING

Before making use of the paint, I used a primer to cowl over the naked foam from the decal areas. Kilz primer and Minwax Polycrylic semigloss helped cowl the froth, however I needed to be cautious whereas masking. For the primary scheme, I used cheap pattern jars of Behr Ultra Satin water-based enamel; these can be found in most home-care shops. I used the Misty Coast shade, which was match for the full-size Stearman; it adhered fairly nicely to the yellow paint. I used a 5/8-inch-wide flat artist brush and utilized the paint to the areas the place the decals have been to assist fill within the floor. I let this space dry after which sanded flippantly to mix it in earlier than making use of the remainder of the paint to the fuselage. I made positive the paint was fully dry earlier than sanding. I used smaller brushes whereas portray the struts, windshield frames, and different small areas.

Once the bottom coat of paint had dried, I wanted to masks off the perimeters of the pink band. I reduce some 1/4-inch-wide strips of masking tape and rubbed the adhesive facet with my fingers to detack it somewhat after which utilized the tape. This helped stop the tape from lifting the brand new paint. Don’t rub the tape down too arduous. While portray the band space, I utilized numerous coats alongside the tape edge, utilizing a fairly dry brush, in order that the paint didn’t run beneath the tape. (This is nice apply to comply with any time you paint alongside masked edges.) I subsequent masked off the fin and rudder blue in the identical means. For the tail, I used artist Matte Acrylic Award Blue paint; these paints are cheap and are available 2-ounce bottles. The blue was somewhat too darkish, so I added somewhat little bit of white to lighten it up. The horizontal stabilizer and elevators have been painted with the identical shade.

If any paint will get within the alignment gap for the underside wing, the attachment pin might not match. So I let the paint dry after which used a no. 6 drill bit to wash out the paint. With the wing in place, I masked off the underside of the wing and painted the stomach space to match the fuselage. As earlier than, I used slim strips of detacked tape.

I painted the cabane struts and the interplane N struts in the identical means. To paint the diagonal braces between the cabane struts, I masked off the cabane struts and sprayed on chrome silver earlier than brushing the grey paint on the struts. The backside mounting tabs for the N struts have been somewhat lengthy and wanted to be trimmed to suit into the wing sockets. I made positive to not drive them into the plastic sockets as a result of they may have damaged off from the wing. The struts have been secured as soon as they have been connected and fixed to the highest wing, and the N struts have been secured to the highest wing by 4 slide-in wire rods. I discovered that tapering the ends of the rods made it simpler to align them within the holes within the struts.

| Tech Tip Don’t use extra paint on the mannequin than obligatory. Paint provides weight to the aft finish and would require the addition of nostril weight to rebalance the mannequin. |

NEW MARKINGS

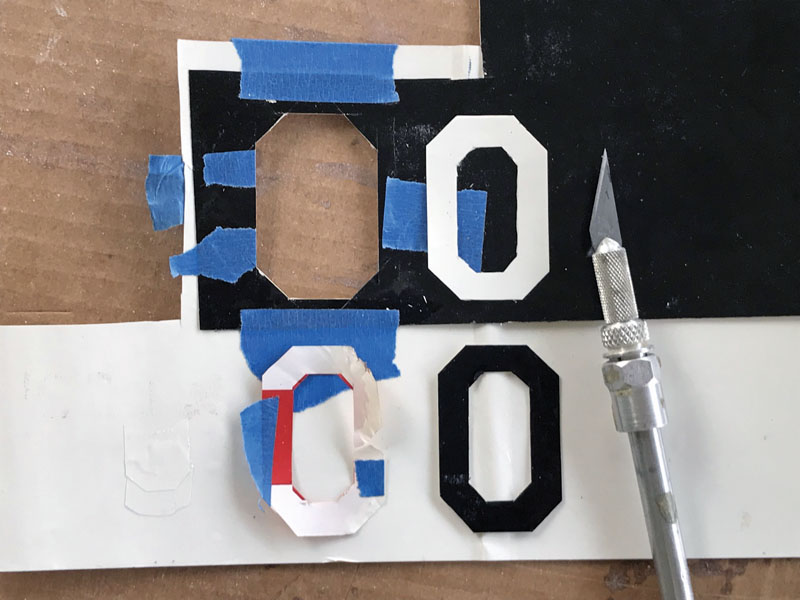

I reduce my new markings from some black-and-white MonoKote trim sheets I had available. To make the brand new numbers and letters roughly the identical dimension as these on the inventory mannequin, I stacked and taped a bit of white and black trim sheet collectively. I then used the inventory quantity “3” (from the outdated decals) as a sample since I may simply make the “0” and the “6” from the essential form of the “3.” I used a pointy mannequin knife to chop out the numbers, utilizing a straightedge to information me. The U.S. Navy markings have been executed the identical means.

To place the brand new markings, I used the highest of the fuselage hatch edge as an alignment information. For reference, the massive numbers have been 3/8 inch under this edge, and the U.S. Navy letters have been 7/8 inch under it. I utilized the brand new markings utilizing the moist approach, making use of glass cleaner to the floor after which sliding the markings round to the proper place. When glad, I pat and squeegeed the letters down, and let it dry within the solar for a few hours in order that they have been bonded tight.

After portray the fuselage, set it apart and begin slicing out your new markings. Here, I’m utilizing the inventory no. 3 decal as a information to kind the brand new numbers.

I used the flat fringe of the battery compartment as an alignment information after which used strips of tape to assist place the brand new markings.

ADDED DETAILING

I reduce out the part hand holds on the wingtips and heart part. A pointy knife blade was required. The 5/8-inch-long rear fuselage hand holds have been shaped from 1/16-inch-diameter aluminum tubing and glued into holes within the fuselage. This was additionally executed for the footsteps that challenge from the entrance of the higher landing-gear fairings. I painted the engine crankcase grey and the exhaust stacks a rusty brown shade. The fueling foot pad on prime of the nostril was simulated with a 1/2-inch-wide strip of black trim sheet sanded to uninteresting the end. There is a small black spec plate on the left touchdown gear fairing that was made out of a bit of trim sheet. The oil-fill cap within the higher rear nook of the left nostril facet panel was made out of a 1/2-inch-diameter disc of black trim sheet and a bit of three/8-inch dowel painted yellow and glued in place. I made the static scale propeller from an outdated Zinger 11x7W propeller. The outer tip was painted a darkish tan shade, and the forefront was painted brass. I didn’t add any weathering to the mannequin, as Nick’s full-size Stearman appears manufacturing unit recent!

Being neat when you do the masking, add small particulars, and paint the cockpit coaming contributes a lot to the look of the airplane. Taking your time makes an enormous distinction. For the small tail-number markings, I had a good friend reduce them out for me utilizing his desktop vinyl cutter.

Small particulars, just like the wing hand holds, might be reduce out and painted to enhance the mannequin’s scale appears.

WIND RIGGING

I made a decision that the Stearman would look higher with flying and touchdown wires. I replicated these utilizing semiflat plastic Creatology lacing materials from the native craft retailer. If you’re fortunate, you’ll find the fabric in chrome, silver, and grey.

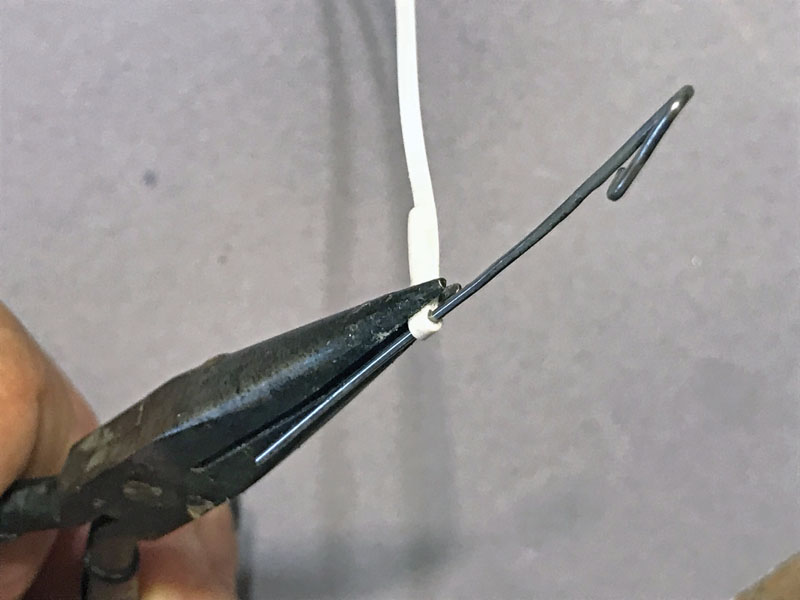

I used white lacing after which painted it with Krylon gloss smoke grey paint. Before portray, I shaped a loop in a single finish of an 18-inch size of the lacing for the wing clips. The lacing materials is flat on one facet and barely oval on the opposite. For higher glue adhesion, I sanded the flat floor utilizing 220-grit sandpaper. I folded the sanded finish over a size of paper-clip wire, utilized some Zap medium CA, held it collectively utilizing small-nose pliers, after which

utilized some Zip Kicker. I made positive the wire clip was free to maneuver, then coated all the overlapped part with CA and eliminated the wire; I didn’t let the glue fill the wire gap. I then pinned the wing rigging between two wooden blocks to color.

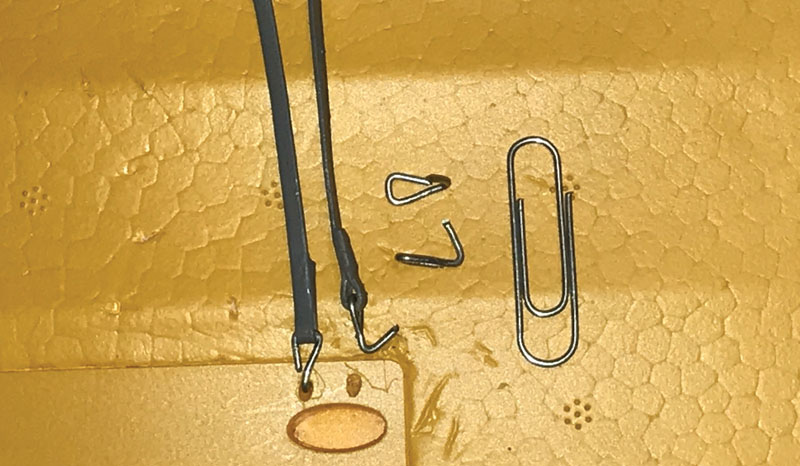

Make the wire clips from a paper-clip and bent to form as proven. My clips shaped simply and are lots sturdy for securing the rigging in place. Make two clips huge sufficient to suit two rigging traces. Assemble the clips to the rigging line loops and drill 1/16-inch holes within the backside of the highest wing on the cabane struts and the N struts. These needs to be positioned about 1/8-inch outboard of the cabane struts and centered on the entrance struts. The rear needs to be drilled in any case the opposite rigging is in place. Check the pictures to see the place the rigging traces are connected.

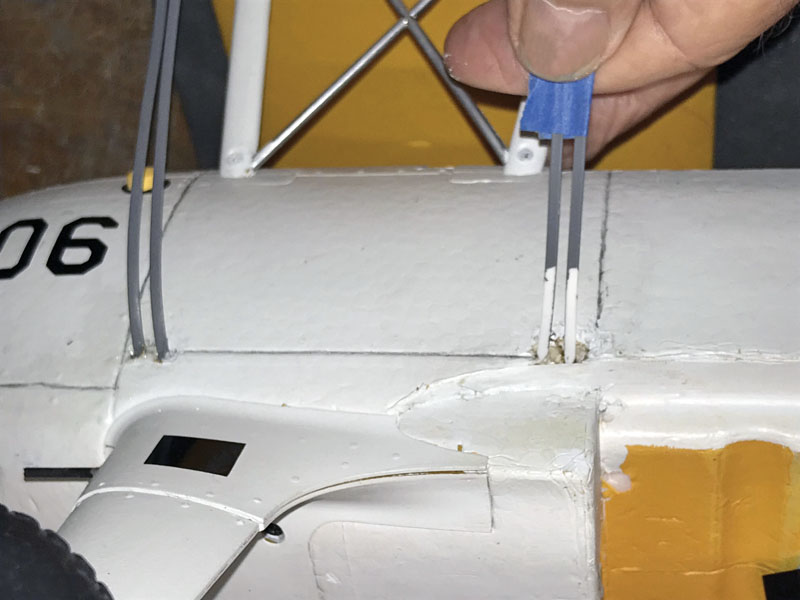

The double flying-wire traces have been epoxied into 1/8-inch holes shaped into the edges of the fuselage. I made these by pushing a small screwdriver 3/4 inch into the froth. (You must take away the underside wing for this. The holes are positioned on the backside corners of the outlined panel on the edges of the fuselage.) With the highest wing and rigging wires hooked into place, I pushed the inboard ends into the holes. I did one set at a time, wiping off the surplus epoxy. My aim was to have the rigging be about 1/2 inch quick. When the epoxy had cured, I stretched the rear flying wires and related them to the holes on the rear N strut. I connected the underside wing and related the double landing-wire traces to the decrease N-strut holes. I repeated the method till all of the wires have been in place.

You would possibly need to think about including 3/32-inch-diameter tie bars on the rigging crossovers. To do that, use a dowel or a rounded size of arduous balsa.

All the wing-rigging wires are actually in place. I additionally added the wire-spreader rod on the crossover part for an added little bit of element.

You can add scale wing rigging to the mannequin with plastic lacing materials. Here, I’m gluing the top loop utilizing a paper clip within the loop and holding the fabric collectively whereas the Zap glue dries.

I bent the wire attachment clips to form from a paper clip, and drilled holes within the plastic plates across the

strut sockets.

BOTTOM LINE

All this was a bit of labor, however the added particulars actually made an enormous distinction. If you’re taking your time and use these methods, you’ll be able to reproduce a scale model of your individual favourite Stearman biplane

|

With the makeover portray full, I rebalanced the mannequin. It flew nice, however it’s nonetheless somewhat plain Jane. The King of the Limo Planes |

Text & pictures by Nick Ziroli Sr.