DIY Smoke Muffler: Turn your plane into airshow performer!

Nothing provides pleasure to your RC flights greater than a smoke system. Do a loop or a roll and add that dense, long-hanging smoke path and you’ve got an airshow! Instead of shelling out the coin for a business smoke muffler, save a couple of dollars and modify your inventory muffler. Then apply your financial savings to the price of a very good smoke pump and the required {hardware}. Here’s how I made my smoke muffler for my Zenoah G20–powered Hangar 9 1/4-scale J-3 Piper Cub.

Image above: A smoke system is a good way so as to add loads of enjoyable to your RC flying.

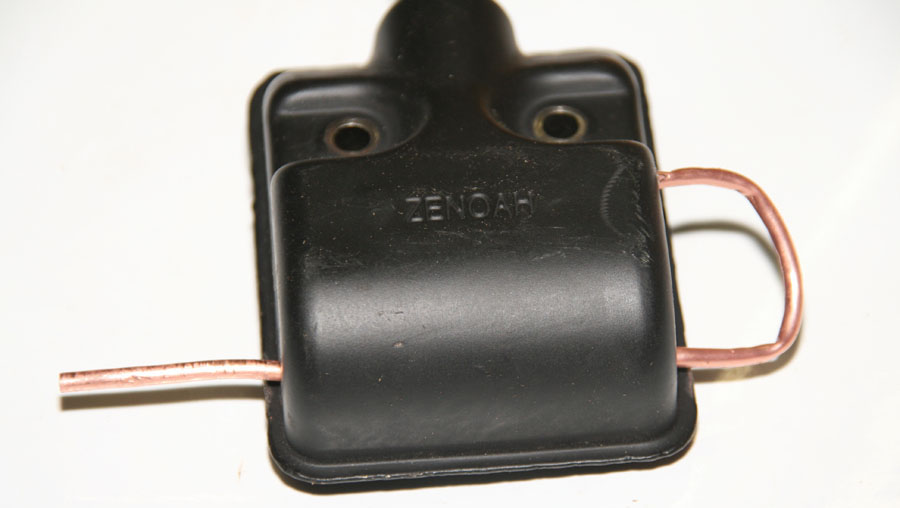

proper: The inventory muffler that comes with the Zenoah G20 engine makes an ideal smoke muffler.

Getting Started

Remove the inventory muffler from the engine, and clear it up with some acetone solvent to degrease it. I used a brand new single-edge razor blade to fastidiously take away the previous exhaust gasket. Here, you’ll be able to see the brand new one which will probably be used after the muffler has been modified.

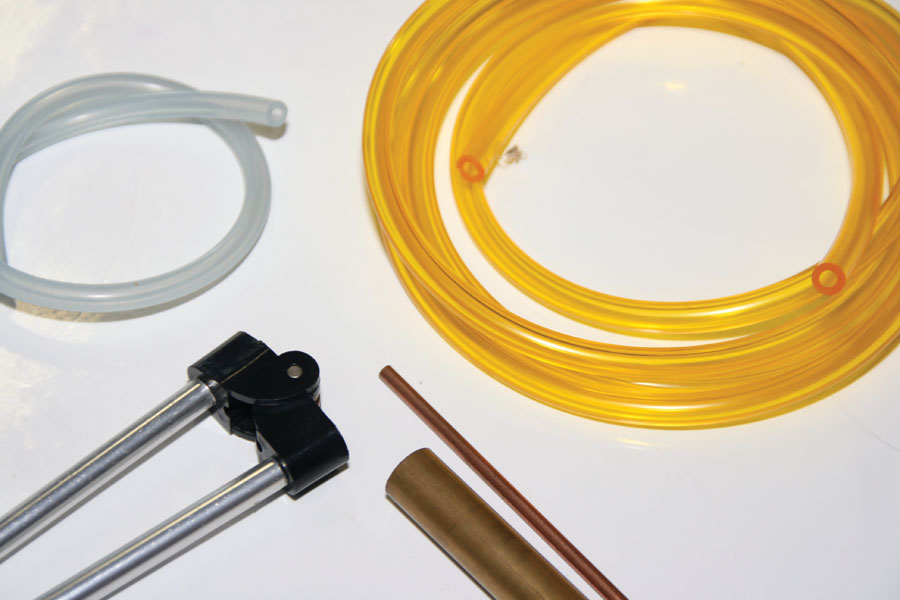

For plumbing, you’ll want a mixture of Tygon gasoline gasoline line and heat-resistant silicone tubing that holds up effectively to the warmth of the muffler. To modify the muffler, all you want is a big brass tube that matches into the muffler’s exhaust pipe (used as a baffle tube) and a size of skinny 3/32-inch copper tube for the oil preheat and injection tube. I used Du-Bro and Ok&S instruments to bend and cleanly lower the metallic tubes. For the smoke oil tank, I used a Sullivan 10-ounce tank with a typical two-tube setup. Be certain to make use of tie wraps to safe your tubing. A chunk of plywood together with double-sided foam tape or Velcro makes your tank and smoke system straightforward to take away for servicing.

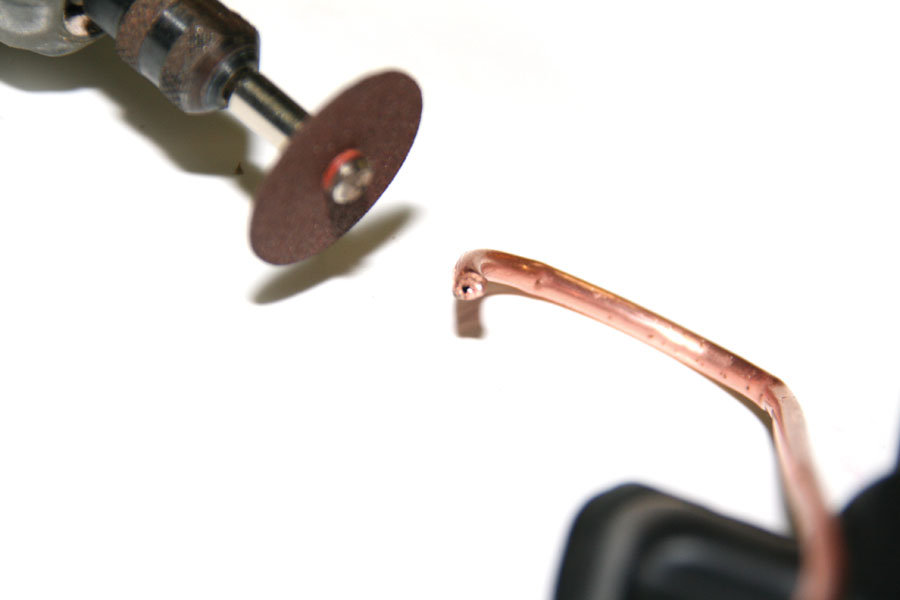

Injector Tube

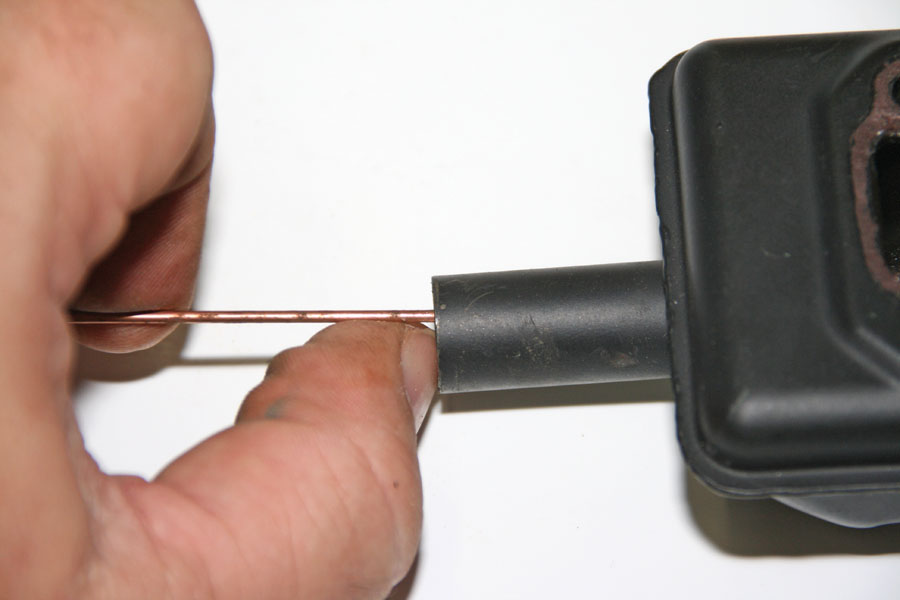

Start by bending and making ready the top of the injector tube. To make a tremendous atomized spray mist of oil contained in the muffler, I used a wire cutter to snip off the top of the copper tube; this squeezes and seals the top and provides it a fishtail form. Use a skinny cutoff disc along with your rotary device to make a small nick in the midst of the fishtail; this produces a gap about half the scale of the inventory tube. Bend the tube to form in order that it’s lengthy sufficient to enter the aspect of the muffler, cross by means of to the opposite aspect, and bend 180 levels to re-enter the muffler.

Drill three holes within the sides of the muffler. Depending in your muffler and engine set up, these holes must be customized laid out. On mine, the only entry gap is on the muffler’s aft aspect, and the 2 others are on the entrance aspect. Drill the holes barely bigger than your injection tube’s diameter. I used a drill bit barely smaller than 1/8 inch (about 0.1 in.). Using a grinding bit, take away the black end on the muffler exposing the naked metallic. This gives a clear floor for the metallic epoxy to stay to.

Here, the injection tube has been put in and is able to be sealed with J-B Weld metallic epoxy. Clean the injection tube in addition to the floor of the muffler with extra acetone, and when dry, combine up some epoxy and construct up neat fillets across the tube/gap areas. Smooth the fillets with a moist finger after which set the muffler apart to totally treatment (about 24 hours).

Baffle Tube

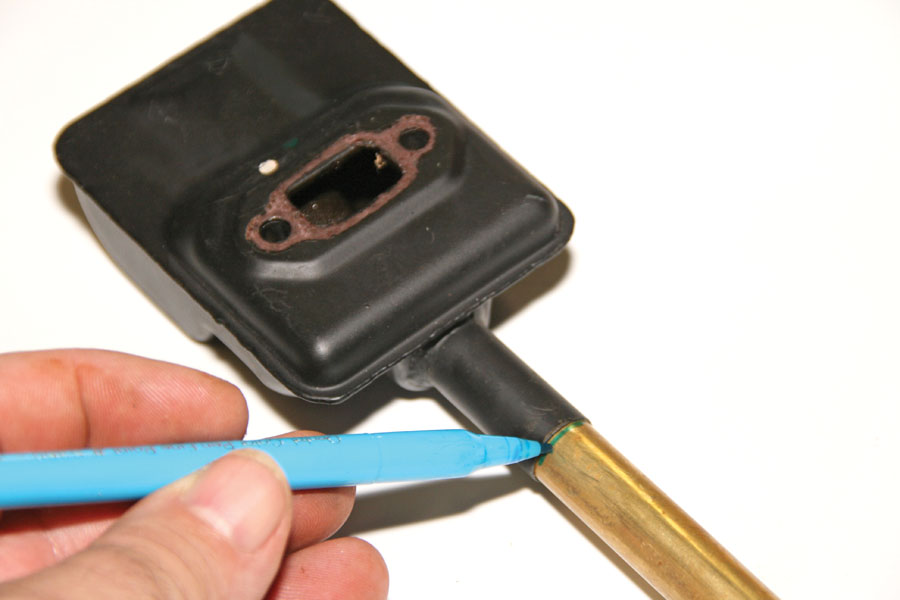

Increasing the metallic space to assist switch the warmth to the smoke oil inside the muffler produces denser smoke. The simplest way to do that is so as to add a baffle tube. Slip a snug-fitting brass tube into the muffler’s exhaust pipe; the tube must be longer than the exhaust tube already inside the muffler. Slip the baffle tube into place till it bottoms out in opposition to the within of the muffler, and mark the size. Use a Ok&S tubing cutter, and lower it to size.

To decide the size of the inner tube, bend a chunk of wire as proven and slide it into the exhaust pipe. Feel for the top of the inner tube, and along with your thumbnail, use the wire as a depth gauge. Transfer the size to the brass tube.

This small space on the finish of the brass tube is the baffle part, and several other holes should be drilled by means of the tube. I used a 1/8-inch drill bit to drill eight holes across the finish of the tube. Remove any burrs from the holes after which sand easy.

Slip the baffle tube into the muffler till it bottoms out and is flush with the top of the exhaust pipe. Drill a gap within the aspect of the pipe and thru the tube, and safe in place with a panhead sheet-metal screw. Loosen the screw barely, add a drop of purple thread-lock, and retighten.

Reattach your DIY smoke muffler to your engine, and if crucial, trim the engine cowl in order that it doesn’t contact or intervene with the smoke plumbing.

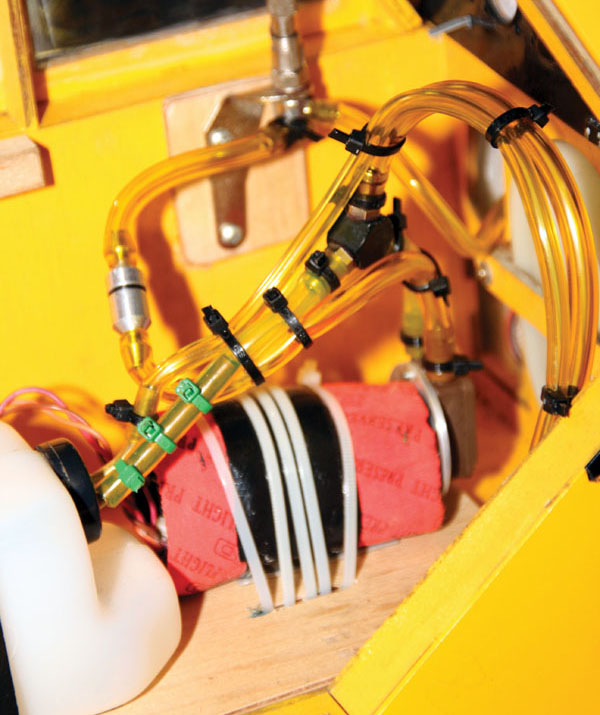

Internal Setup

A detachable smoke system is an effective solution to go as you’ll be able to take away the general system for servicing. It is so much simpler to work on every part outdoors of your mannequin than with it crammed into the fuselage. For my Piper Cub, I merely eliminated the cabin particulars and seats, and used the pilot space for the smoke-system set up.

You want to control your smoke-fluid move. Injecting an excessive amount of smoke oil into your muffler is worse than utilizing too little. The extra oil truly cools your muffler, and this reduces the quantity of smoke it generates. This additionally shortens your “smoke-on” time by burning up the fluid quicker than wanted. I used an auxiliary needle-valve meeting from an previous glow engine to fine-tune the quantity of oil coming into the muffler.

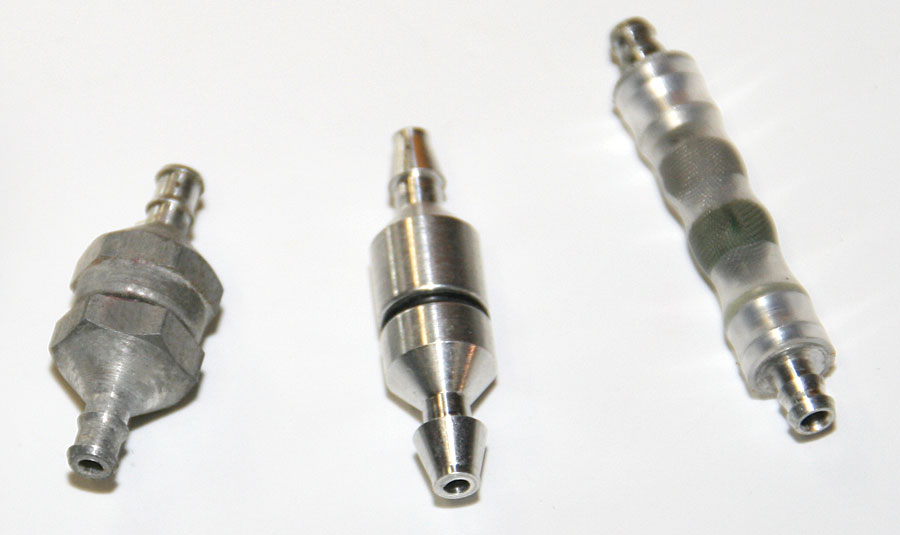

Be certain to make use of gasoline filters between your smoke tank and your switch pump. Try to not change in your smoke pump when your engine is at low throttle or at idle; this could trigger the engine to drown on the unburned oil, which will increase again strain. A good suggestion is to combine the smoke change along with your throttle channel and set the “on” place to 1/4 to 1/3 throttle.

Final Installation

Drill a gap within the firewall, and route your smoke traces into the cabin space. A stiff size of wire fed by means of the opening can be utilized to information tubing into the cabin. Attach the smoke line to the wire, and pull it into place. At the muffler finish of the smoke line, insert a brief size of aluminum tube and slip on a 1-inch-long piece of glow-fuel silicone. Attach the silicone tubing to the muffler’s injection tube. Silicone stands up effectively to the muffler’s warmth. Connect the smoke line to the needle-valve meeting, and join the needle valve to the output becoming of your smoke-oil pump.

Attach the smoke-oil tank to the pump’s enter becoming, and plug the pump’s energy lead into your receiver. I exploit a T-fitting between the tank and the pump for filling and emptying the tank, and use a gasoline dot to seal the fill tube. Be certain to additionally connect a vent tube to your smoke tank, and route it out of the fuselage.

Check out the smoke density! This is what it seems like when the oil move is decreased (just one flip open). This provides an ideal “smoke-on” time, and my 10-ounce smoke tank lasts for greater than 10 minutes.

Give this system a attempt! This DIY smoke muffler works simply in addition to any commercially out there muffler. Smoke on, and have enjoyable