With the advent of 3D printing, there are a plethora of printers that can be purchased. Because of the number of printers to choose from, it can be a daunting task to pick the right one for your application. For a few years I have been using 3D printing and design for my RC aircraft, mostly designing and printing small new or redesigned parts. I wanted a larger build platform, and chose the Creality3D CR-10S Pro 3D printer, a 300 x 300 x 400mm build platform. Its tall build area lets you design and print larger pieces, like wings and tail surfaces, in one piece. This $599 printer is also “hackable,” meaning the printer is completely open source, allowing for add-ons or upgrades of almost all the components.

OVERVIEW

The printer came pre-assembled and packaged well. It was ready to print in about 20 minutes, after I screwed to the base and connected a couple of cables to the stepper motors and a large ribbon cable next to the filament runout detector.

The aluminum gantry frame is excellent and anodized black. The frame has two 2040 extrusions for the sides and a single 2020 extrusion for the top. I find the use of dual z-axis screws a plus as they provide a much more stable x- axis for the hot end and carriage. Creality uses a stepper motor for each z-axis lead screw instead of using a single motor and a belt.

This PC-21 canopy printed flawlessly and is the best printed part I have made to date. The detail is amazing.

This PC-21 fuselage section is the second part I printed, and it also came out really well.

A built-in touch screen in the base allows fast and easy access to printer functions and settings. You can also level the bed without a G-code file: you press one of the five positions and adjust the bed height using the four wheels on the four corners of the bed. The printer comes with a feeler gauge for this, however I found that using a piece of A4 paper gave me a better print. When you have completed the manual level, press the “check level” button and the printer will automatically check the bed level at 25 different points.

The CR-10S Pro comes with a BondTech anodized red aluminum extruder and Capricorn Teflon PTFE tube that allow the printer to handle high-performance products that melt at a higher temperatures. An aluminum runout sensor is in front of the extruder, and the hot end has a dual fan setup for cooling.

The CR-10S Pro comes with a boot loader pre-installed should you want to flash the firmware. I haven’t done this yet, but I am going to since the factory-installed firmware does not have the Thermal Runaway protection installed.

The last item to mention is the bed. The CR-10S Pro comes with an aluminum plate with a rough surface build sticker applied. The surface works quite well and I had minimal issues with parts coming loose. I always clean the surface with 80% alcohol before every print, use a bit of Elmer’s purple craft stick glue on the bed, and slow the print down to about 40% when it starts printing the first few layers.

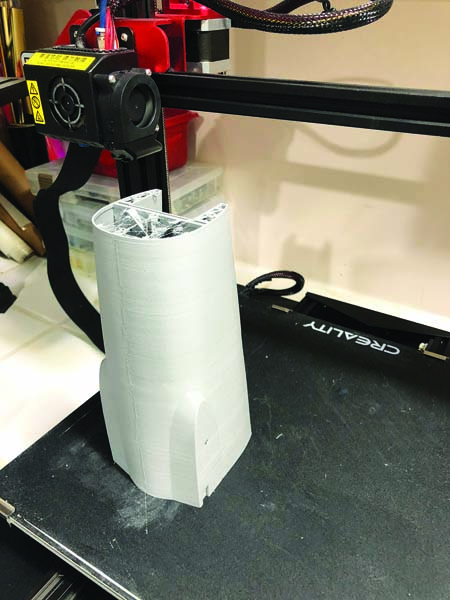

PRINTING PARTS

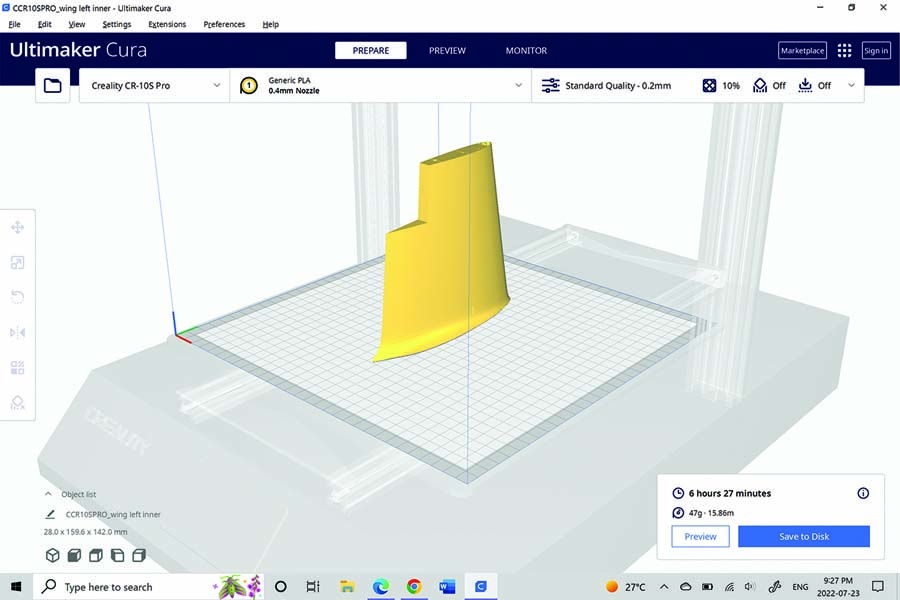

It’s quite simple, the printer just works the way that you would expect it should. I used Ultimaker Cura as my slicer program, this is a simple setup with the CR-10S Pro within Cura. I wanted to print an aircraft for this article with the CR-10, so I worked with Mark from 3D_Aeroworks on Instagram. He is a 3D printed RC aircraft designer with a wide range of aircraft on RC3DMarket.com, including a P-47, a Spitfire, and the Pilatus PC-21 that I used for this article.

The printer came with a large assortment of filaments but I wanted to use the material intended for this aircraft: lightweight PLA (LW-PLA) so I bought some from MatterHackers separately.

The CR-10S Pro that I tested is a Version 1. Version 2 has an upgrade to BLTouch to help in leveling the print bed. However, if you still have issues, the YouTube site “Tiny Machines 3D” has a great tutorial. I also have leveling advice on my Instagram page, all.rc.aircraft.

I used Ultimaker Cura as my slicing program, and it was easy to set up with the CR-10S Pro.

Here is the completed 3D_Aeroworks PC-21 before the first flight and before painting and decals.

Printing was straightforward with minimal issues. The MatterHackers Creality CR-10S Pro is definitely a top pick for your RC 3D printing needs. Overall, the printer is quiet, easy to use and provides great print quality out of the box without much fuss.

matterhackers.com

By John Dueck