Hard landing? You need these easy repair tips!

My 1/3-scale Fokker Triplane that I constructed from the Balsa USA equipment flies properly and has a formidable presence within the sky and on the flightline. If there’s something I’ve discovered piloting this World War I tail-dragger, is you can’t rush the landings. Recently, I acquired just a little excited on touchdown at a brand new flying subject, and I bounced the landing. Before I knew it, my tire was operating down the runway, and I had a bent touchdown gear. That was the tip of flying for that day!

Before you pack up your dented fowl, remember to choose up each single piece of runway confetti and place all of the little bits and items in a bag for the journey house. Back within the workshop, you may clear up your mannequin and take away the touchdown gear. The subwing is made out of balsa and light-weight plywood, so the restore supplies you want are your typical assortment of sandpaper, primer, interest knife, and razor noticed. To piece the damaged components again collectively, I take advantage of Zap CA, 1-oz. fiberglass material, and automotive spot putty.

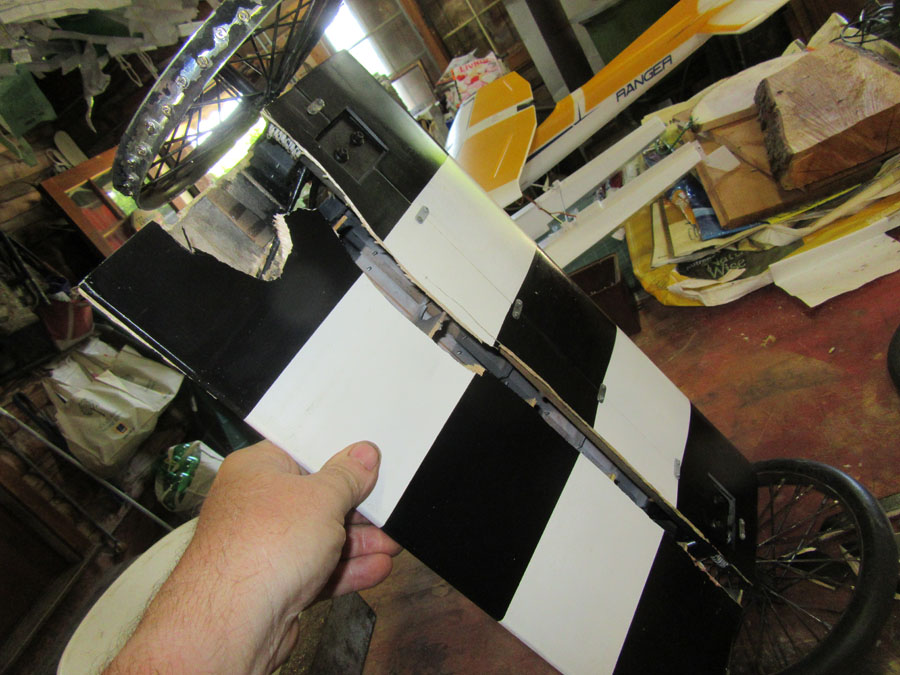

ONE:

This isn’t a fairly sight. You can see right here that the landing-gear struts (3/16-inch music wire) are fairly bent up and the subwing is damaged in a number of locations. The tire additionally peeled off the rim. So the very first thing to do is to take all the things aside and examine for different broken components.

TWO:

The aft part of the subwing was cut up in two, so I eliminated the damaged components and unscrewed the ahead and rear sections in order that they may very well be separated from the gear.

THREE:

The wire struts are pretty straightforward to straighten utilizing a bench vise, a pair of vise grips, and perhaps a ball-peen hammer. Here, you see the gear is sort of completely straightened with just a bit tweaking to do.

FOUR:

To examine the gear alignment, I reattached the touchdown gear to the fuselage (nonetheless within the trailer) after which took measurements between the axles and the tail put up. Once happy, it was again to the workshop.

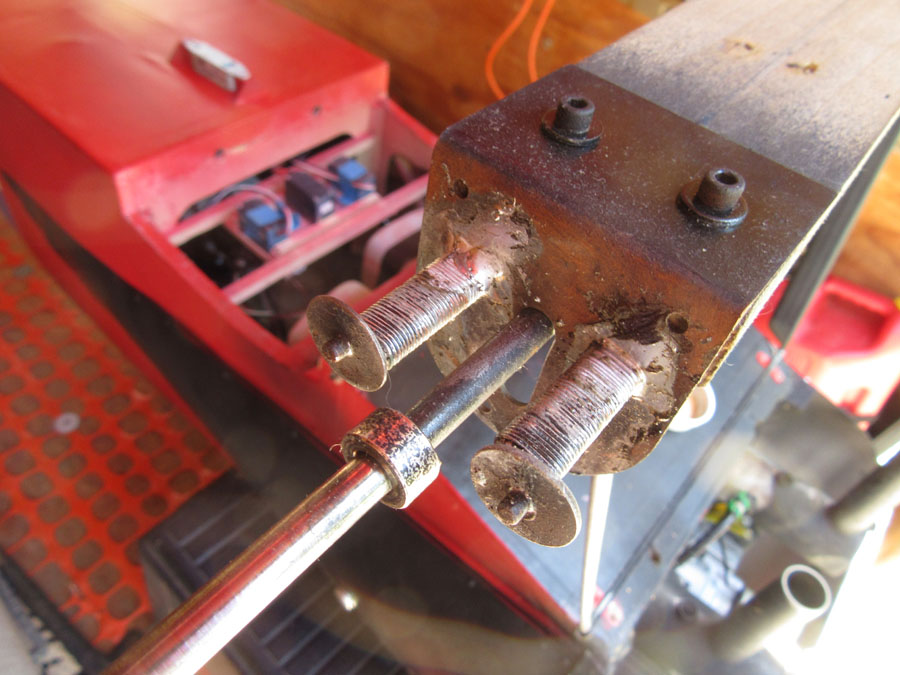

FIVE:

A better inspection additionally revealed some cracked solder joints for the bungee standoffs. After I cleaned it utilizing a wire brush and a few sandpaper, I resoldered the joints utilizing some Stay Brite flux and my 60-watt soldering iron. The high-silver-content solder flows simply into place.

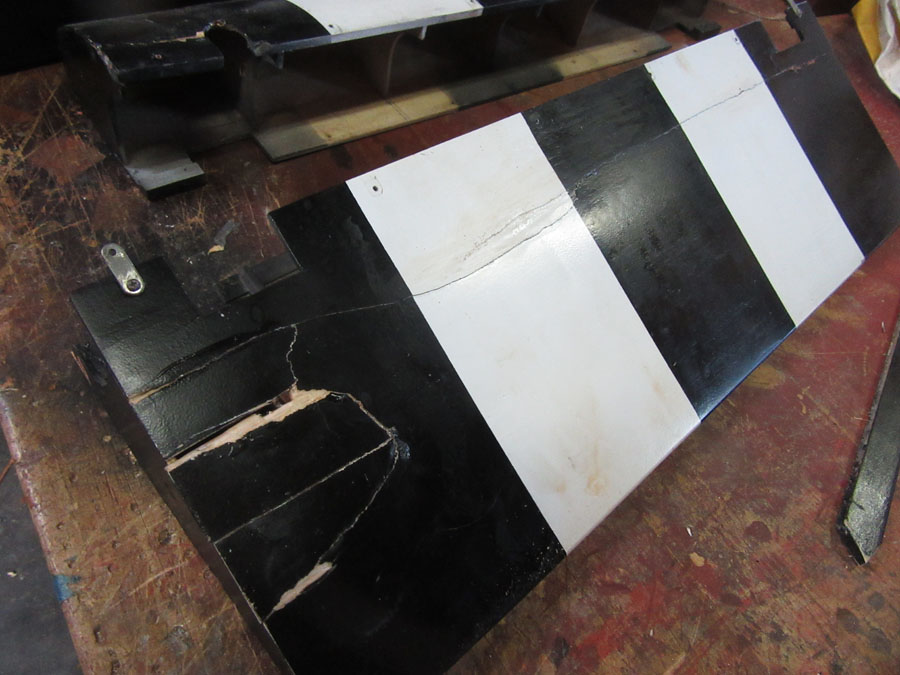

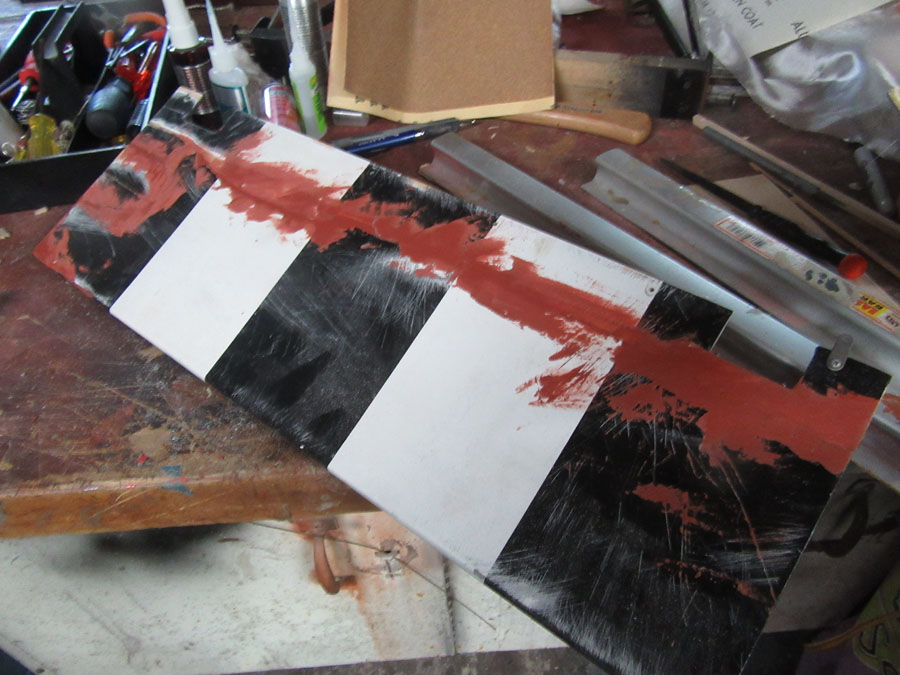

SIX:

Back to the subwing fairing, I reevaluated the injury. Most of the damaged items have been usable, however some simply weren’t.

SEVEN:

Here, the underside floor has some items glued again into place. I used skinny Zap glue and punctiliously flowed it into the cracks to carry the components collectively. Once they have been in place, I added some swatches of fiberglass material to the within to bolster the restore areas.

EIGHT:

For areas that have been too badly broken to piece again collectively, I lower away the injury and changed the sections with new 1/8-inch balsa sheeting. Here, you see the balsa glued in place and a tenet to outline the position of the brand new gear-strut slot.

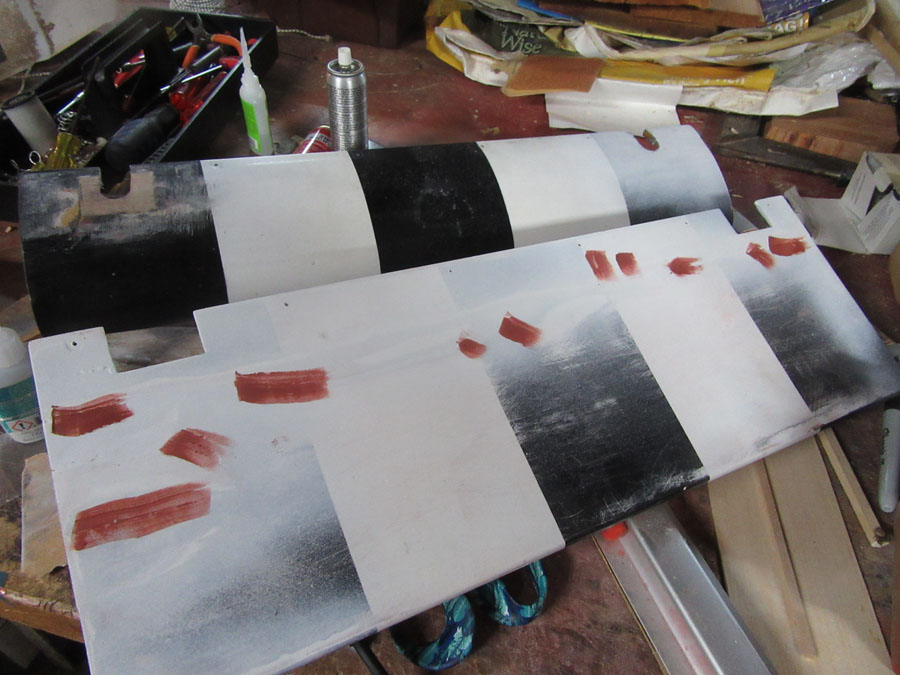

NINE:

With just a little sanding and a few spot putty to fill the cracks, this part was then lined with two layers of fiberglass material. Each layer was glued in place with cautious utility of skinny Zap glue. This goes shortly, and you may see white areas of the fabric’s weave the place extra glue is required.

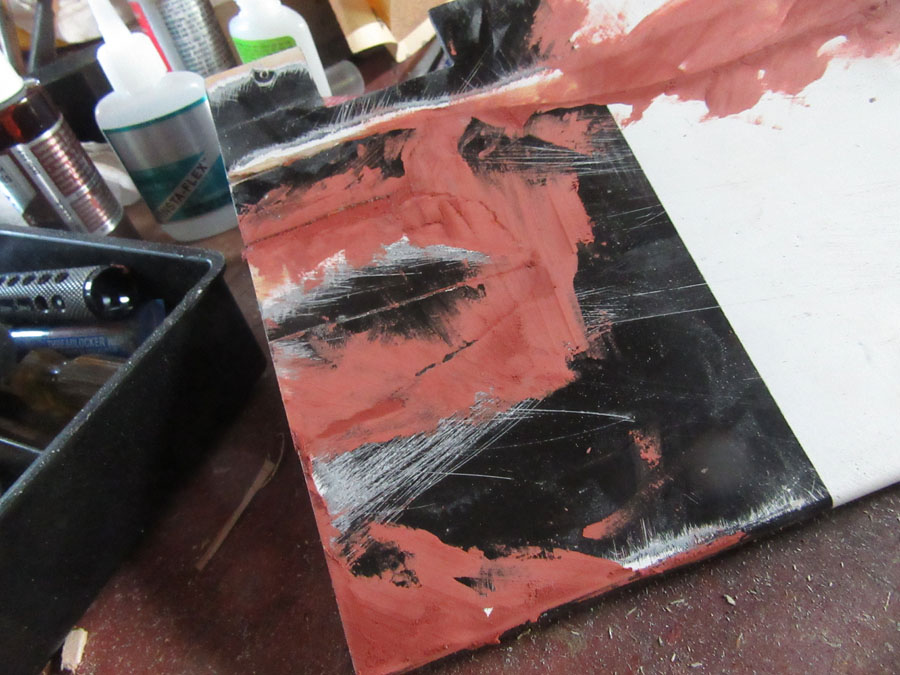

TEN:

On the alternative aspect, much more materials needed to be eliminated and changed with new balsa. Again, the restore space is sanded easy, with some spot putty utilized to the cracks. Everything is sanded easy and flush with the remainder of the fairing.

ELEVEN:

I utilized skinny coats of spot putty to the restore areas after which let it dry fully earlier than sanding.

TWELVE:

Here, the world has been sanded easy; only a few areas want just a little extra putty.

THIRTEEN:

On the underside of the fairing, the broken areas get the identical therapy of a number of coats of spot putty and sanding.

FOURTEEN:

Here, the lengthy break line obtained extra putty and sanding till the broken space was constructed again up easy and flush once more.

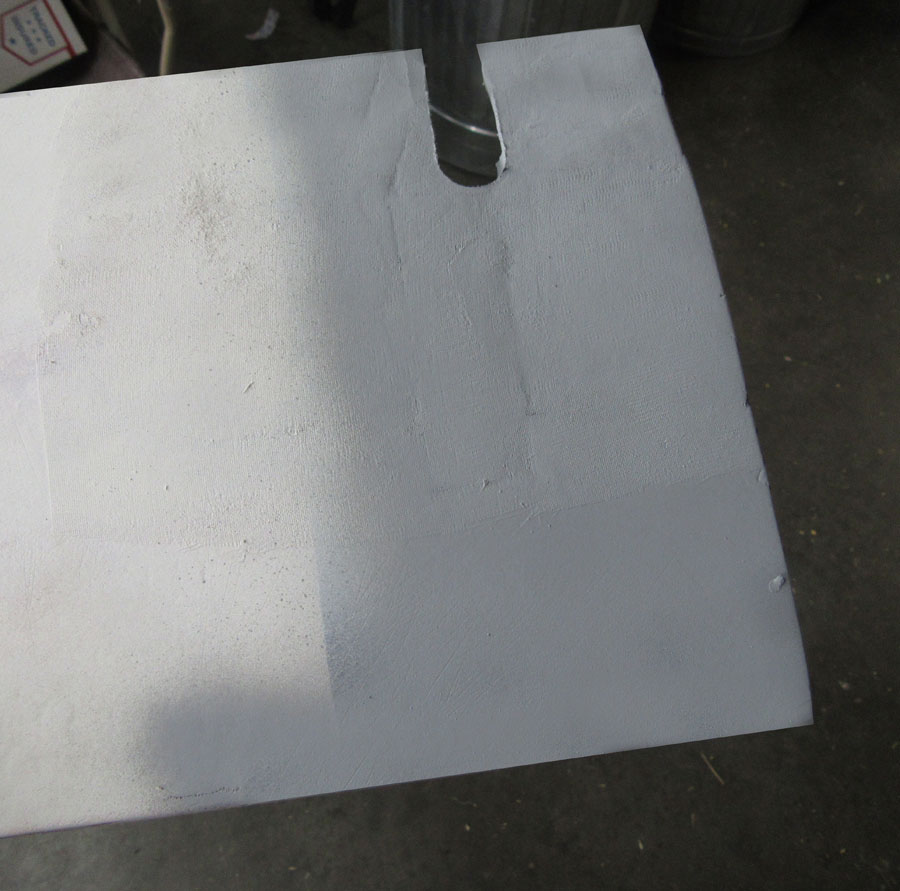

FIFTEEN:

Once the repairs look good and easy, shoot on a light-weight coat of sanding primer (I take advantage of Krylon). Areas that want extra filling present up with tiny pinholes; these are, once more, handled with a skinny smear of putty and extra sanding.

SIXTEEN:

The restore space is all patched up, however the floor isn’t easy and even. Yep, extra putty and sanded is required.

SEVENTEEN:

The space is now good and easy, and a contemporary coat of primer exhibits that there’s little to no signal of the restore. The identical method was used with the opposite broken part till I had a easy and properly primed subwing. I let the primer dry for a day or two earlier than portray.

EIGHTEEN:

The remainder of the method is fairly simple. Apply the lighter-color paint first, let it dry, after which masks and apply the darker colour. I let freshly painted components dry in a dust-free space away from the workshop. Let every colour dry for a day earlier than making use of the subsequent colour. Then let all the things dry once more for a day or so earlier than making use of a protecting clearcoat. Three coats of clear does the trick.

NINETEEN:

With the painted components drying, I went again to the landing-gear struts and added new landing-gear-strut fairings. These are constituted of strips of basswood which have grooves lower within the edges to simply accept the wire struts. I used 15-minute epoxy to connect them in place, then I wrapped them and the wire struts with a layer of fiberglass material. Here, they’ve been primed and sanded. A few remedies with spot putty, adopted with extra sanding, and the gear might be prepared for portray and clearcoat.

TWENTY:

Before the subwing fairing may be reattached to the touchdown gear, I needed to lower new bungee cords to size, bind them collectively to kind a loop, then wrap them across the standoffs and over the axles.

TWENTY ONE:

Back on the flying subject, the freshly repaired touchdown gear helps the triplane as soon as once more. Slightly extra silicone adhesive has been utilized to the free tire, and it’s again in place across the wheel’s rim. In all, this restore took a few days unfold over two weekends to finish.

Bottom Line

So that’s it: one other landing-gear restore made and the triplane is once more airworthy. I’m getting good at all these restore; I simply must do higher within the touchdown sample! So don’t really feel down in case you injury your plane. It’s all a part of the interest, and as they are saying, “What doesn’t kill you (or your model) makes you stronger!”

Text & pictures by Gerry Yarrish