Back to Basics Tech tips for engine & radio installation

Continuing our constructing undertaking for the Phoenix Model Sonic Mk II low-wing sport flier, we get again to the fundamentals. In our “Build it Right” article within the August 2021 concern, we went from components within the field to a totally assembled airframe.

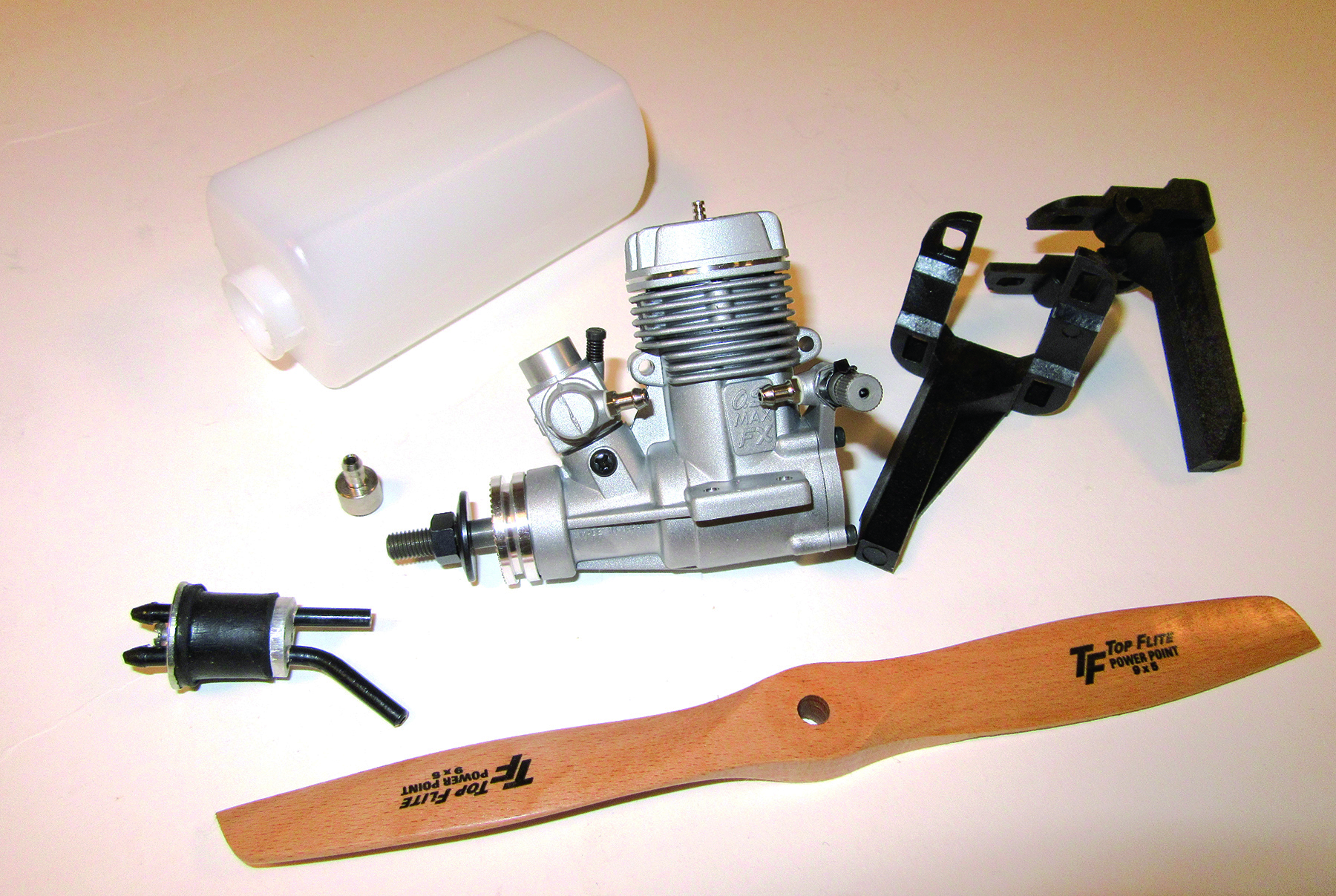

With this text, we’ll spotlight the set up of the facility system consisting of the O.S. Max .25 two-stroke glow engine, its motor mount, the gasoline tank, and the gasoline strains. We’ll additionally set up the receiver and the remainder of the servos within the airplane to regulate the rudder and elevator, and fix all of the management linkages. Let’s get began.

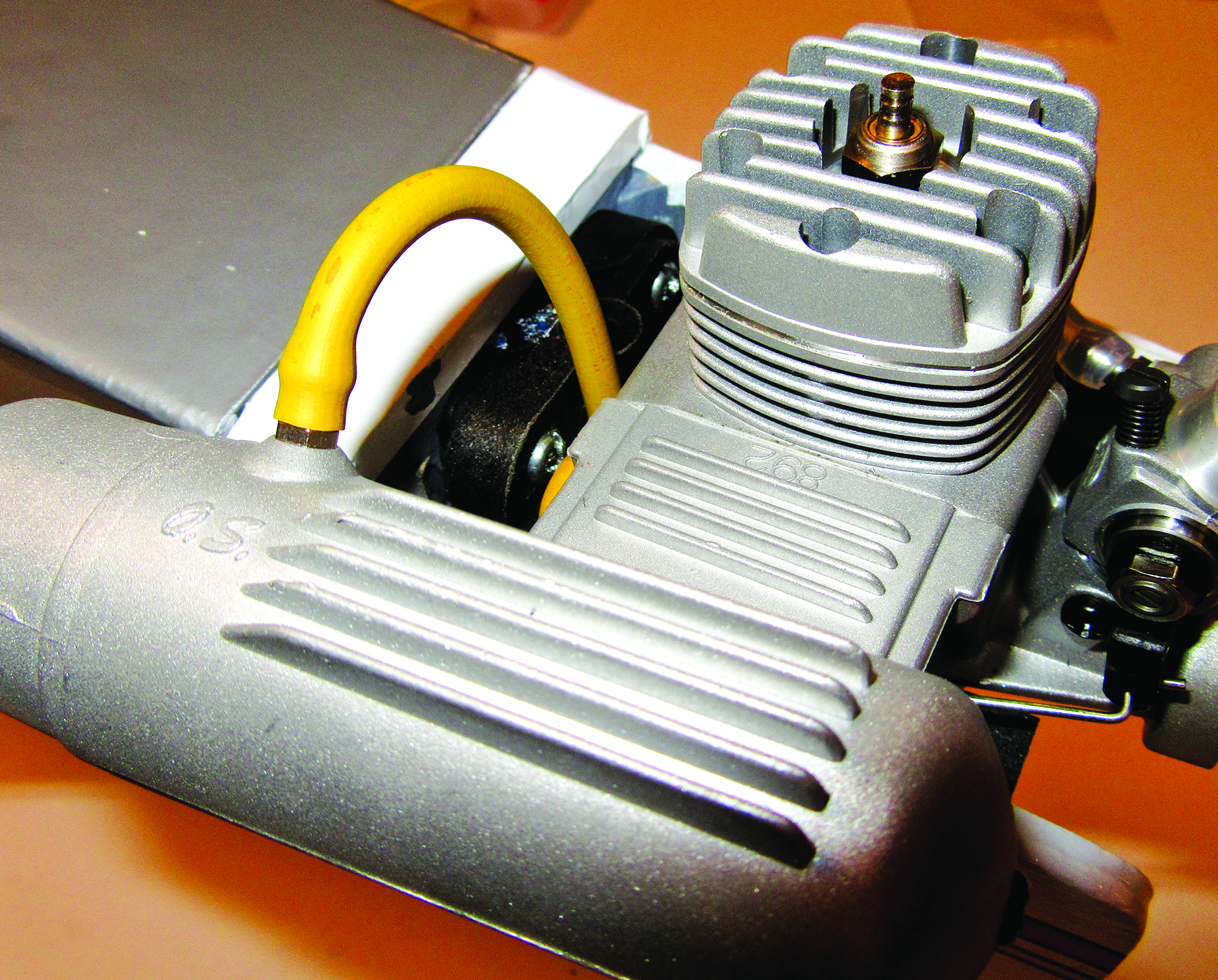

ENGINE INSTALLATION

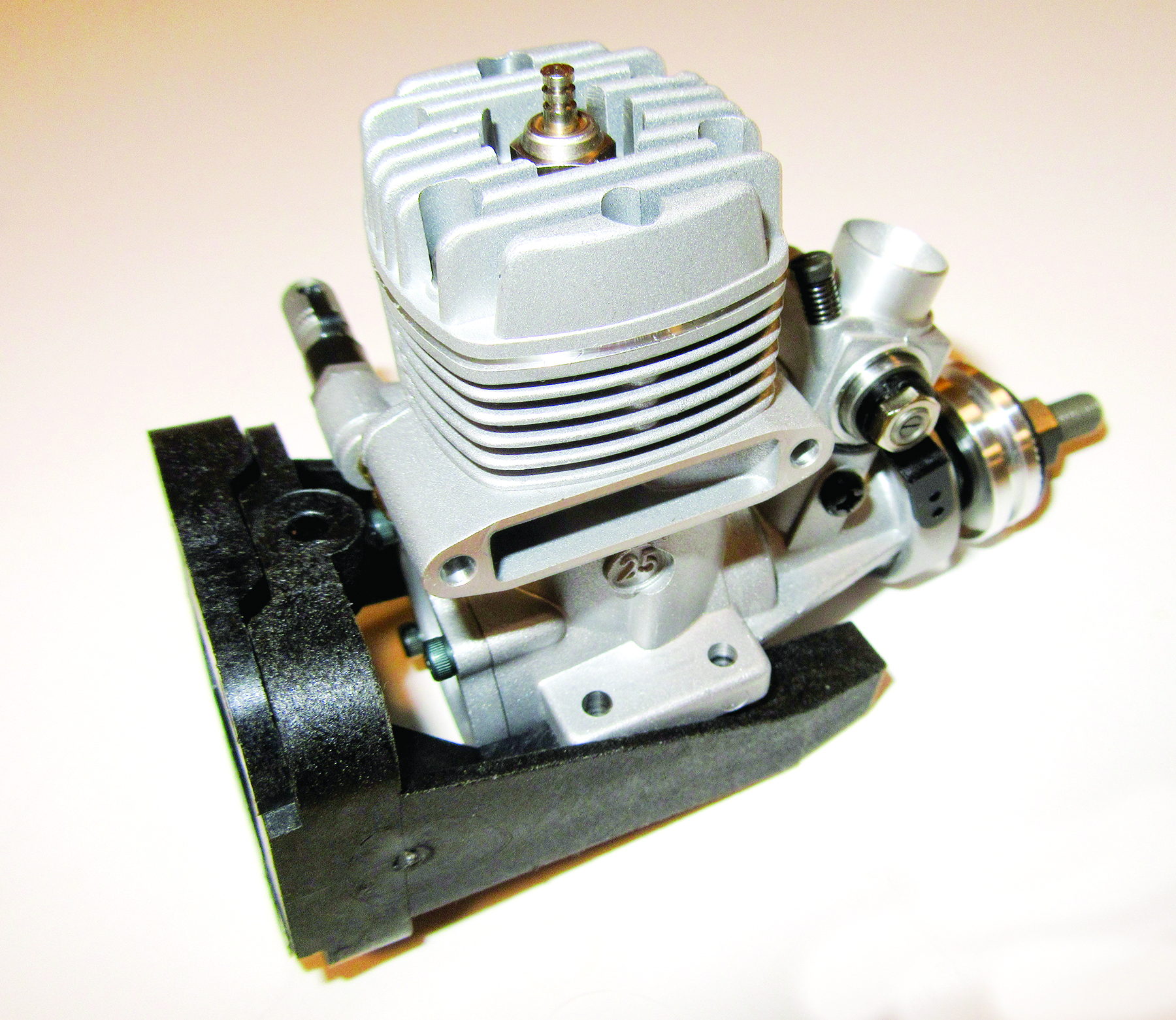

The Sonic ARF comes with a composite engine mount, and it’s molded in two items in order that its width might be adjusted to accommodate a wide range of engines. The two back-plates overlap and may slide backwards and forwards, altering the space between the 2 rails. Slip the 2 halves collectively after which place the engine in the midst of the rails in order that it suits between the 2 aspect webs.

Once you’ve gotten the engine-mount components “sized,” take away the engine and place the again of it on a flat floor; press the components collectively in order that the again is flat with the 2 items flush to one another. Now add a few drops of skinny Zap CA glue, and spritz with a bit of Zip Kicker to carry the components collectively.

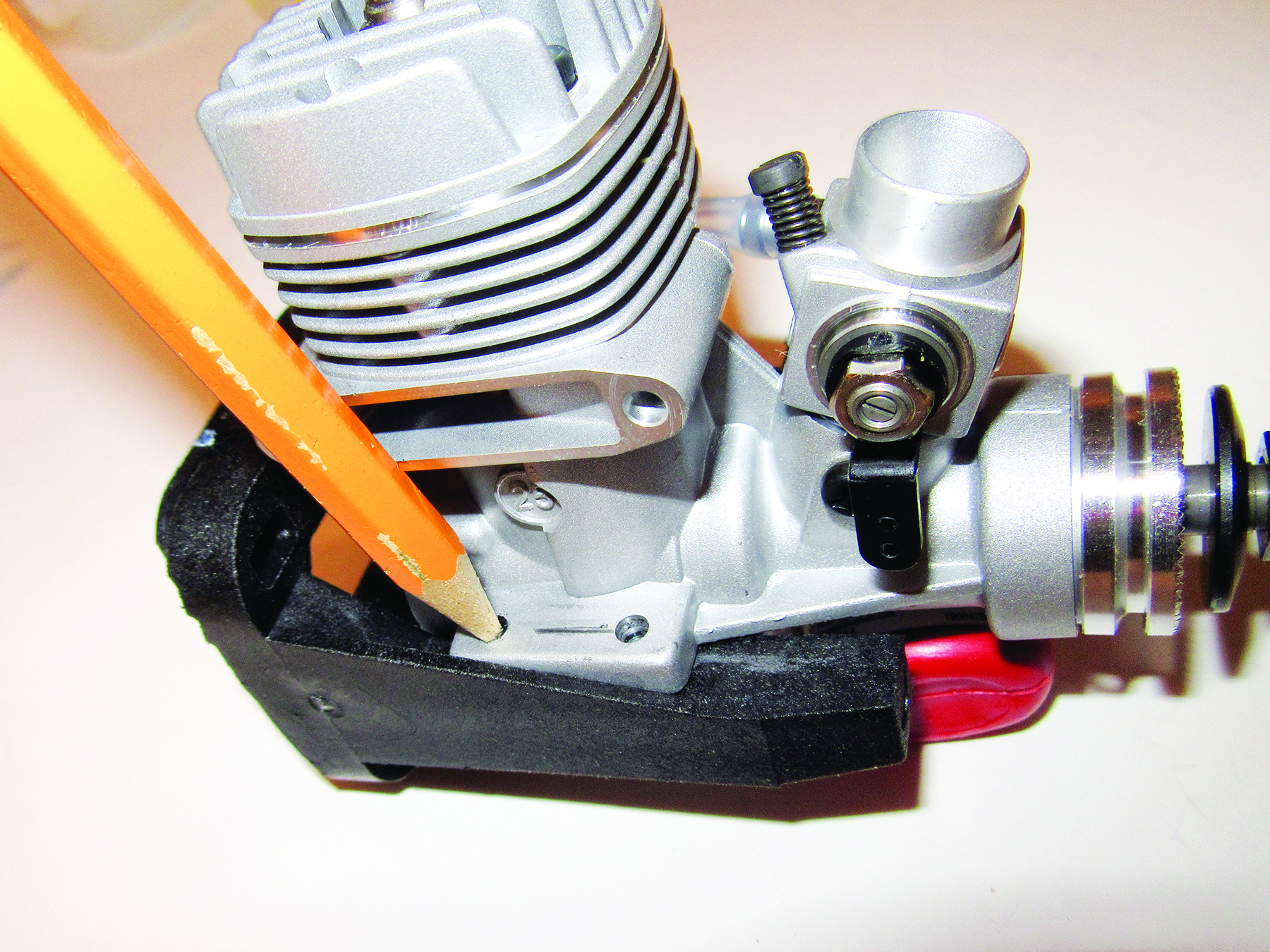

To connect the engine to the engine mount, you first should drill holes into the rails and use the included screws to safe it into place. Position the engine on the engine mount in order that the engine’s attachment tabs are in the midst of the rails, then use a pointy pencil to switch the areas of the outlet onto the tops of the rails.

Using a 3/32-inch drill bit, rigorously drill the 4 holes. Make positive you drill the holes in order that they’re straight vertically and sq. to the rail tops.

Use the 4 2mm x 3/4-inch-long self-tapping screws; insert one by one, and screw them into place a few quarter inch deep to begin the threads. Then take away them.

There are 4 lengthy 4mm screws that maintain the engine mount in place. Insert the screws into the mount and thread them into the blind nuts put in within the firewall. If there are any burrs, it could be tough to string the screw into place. Replace the blind nut with a brand new one. As you thread the screws into place, add a small drop of Zap thread-lock on the tip of the screws, and use a crisscross sample to tighten the screws snugly into place.

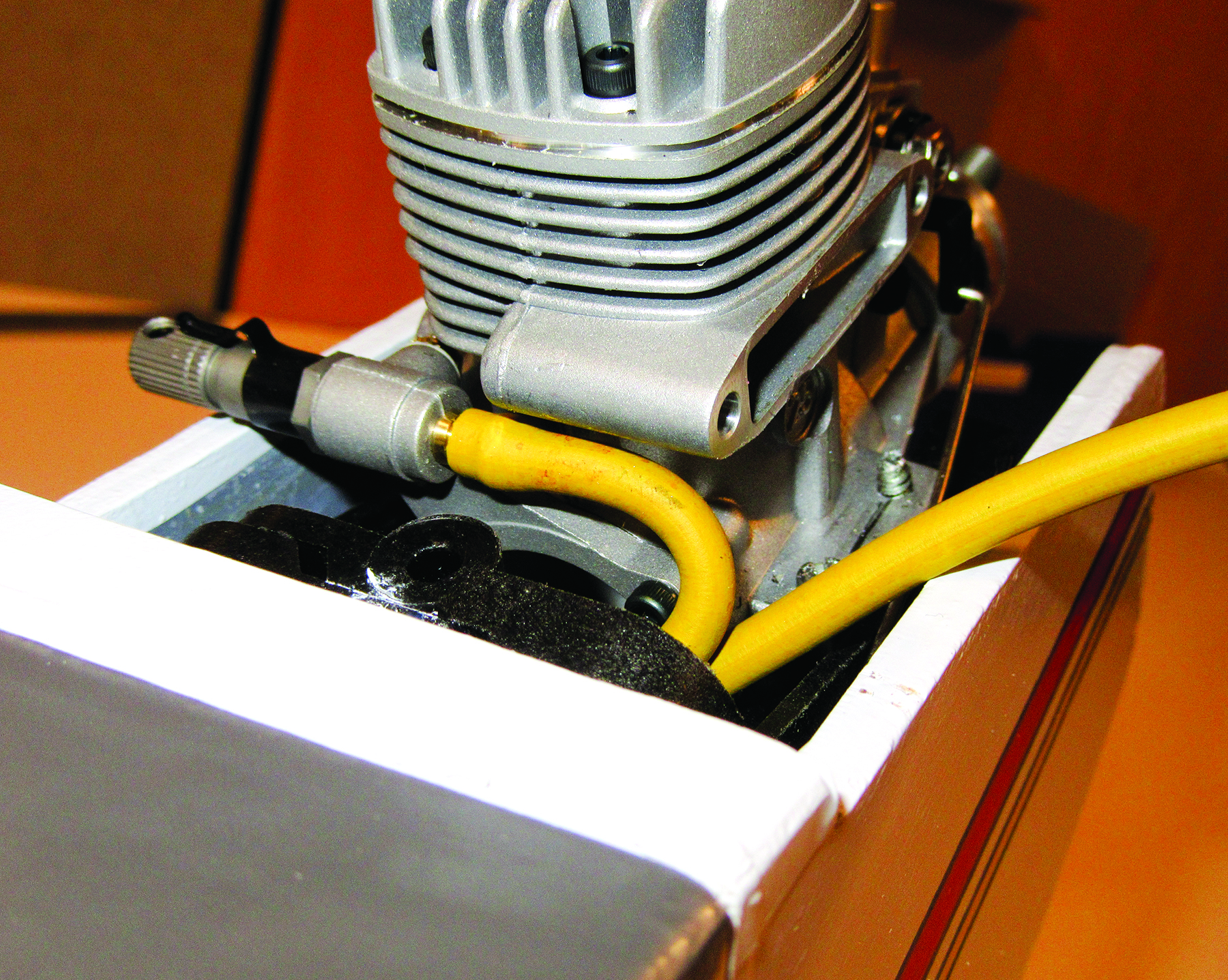

With the engine mount safe, connect the Z-bend finish of the throttle pushrod to the engine’s throttle arm, and place the engine on the mount whereas slipping the pushrod into the information tube. Reinstall the engine on its mount, and tighten the attachment screws snugly into place. (Note: To forestall damaging the gasoline line connecting the carburetor to the needle-valve meeting, take away it earlier than screwing the engine in place.)

TECH TIP 1

Although the included {hardware} is greater than robust sufficient for the job, it’s possible you’ll discover it simpler to exchange the engine attachment screws with 2mm cap-head screws with the intention to use a ball-driver Allen wrench to string them into place. With fixed use, the slots in Phillips-head screws will usually start to wear down.

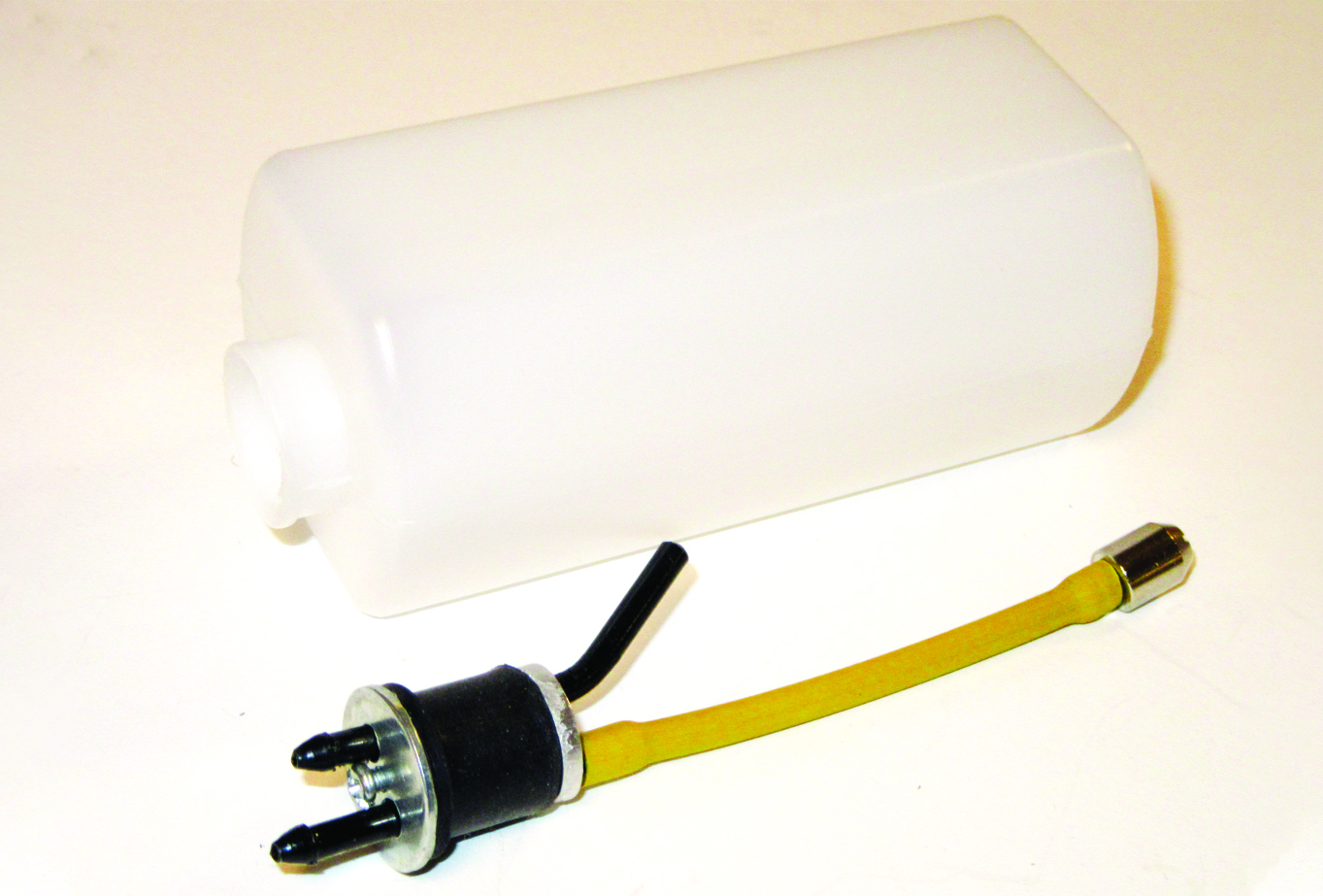

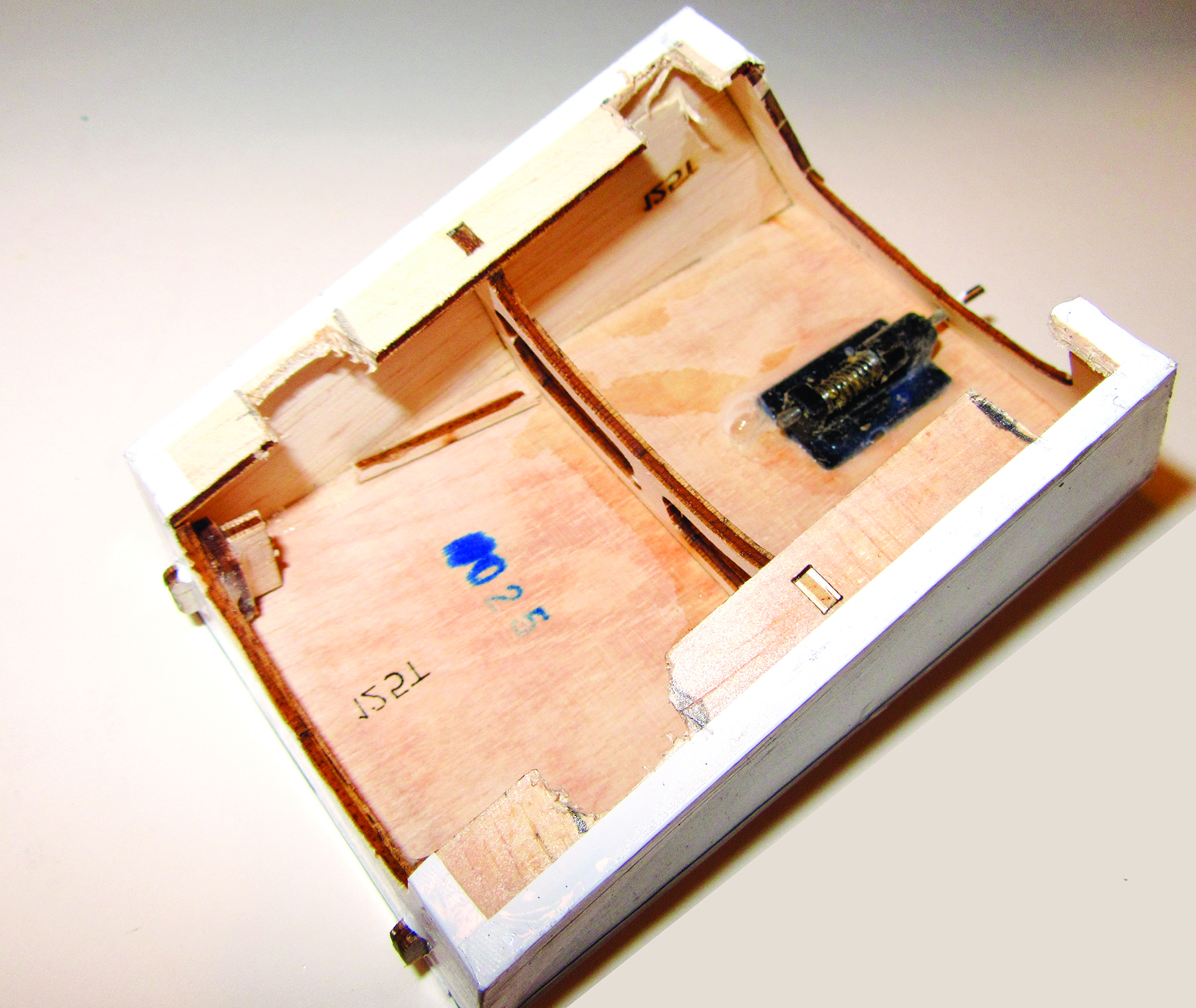

FUEL TANK

The Sonic ARF comes with a gasoline tank and its stopper and outlet tubes, however you must provide the gasoline line. Any glow gasoline tubing will work, however I’ve discovered that the brand new ProFlex Universal Fuel Line works extraordinarily effectively. It doesn’t harden over time and is extraordinarily versatile, which helps forestall it from slipping off of the gasoline fittings.

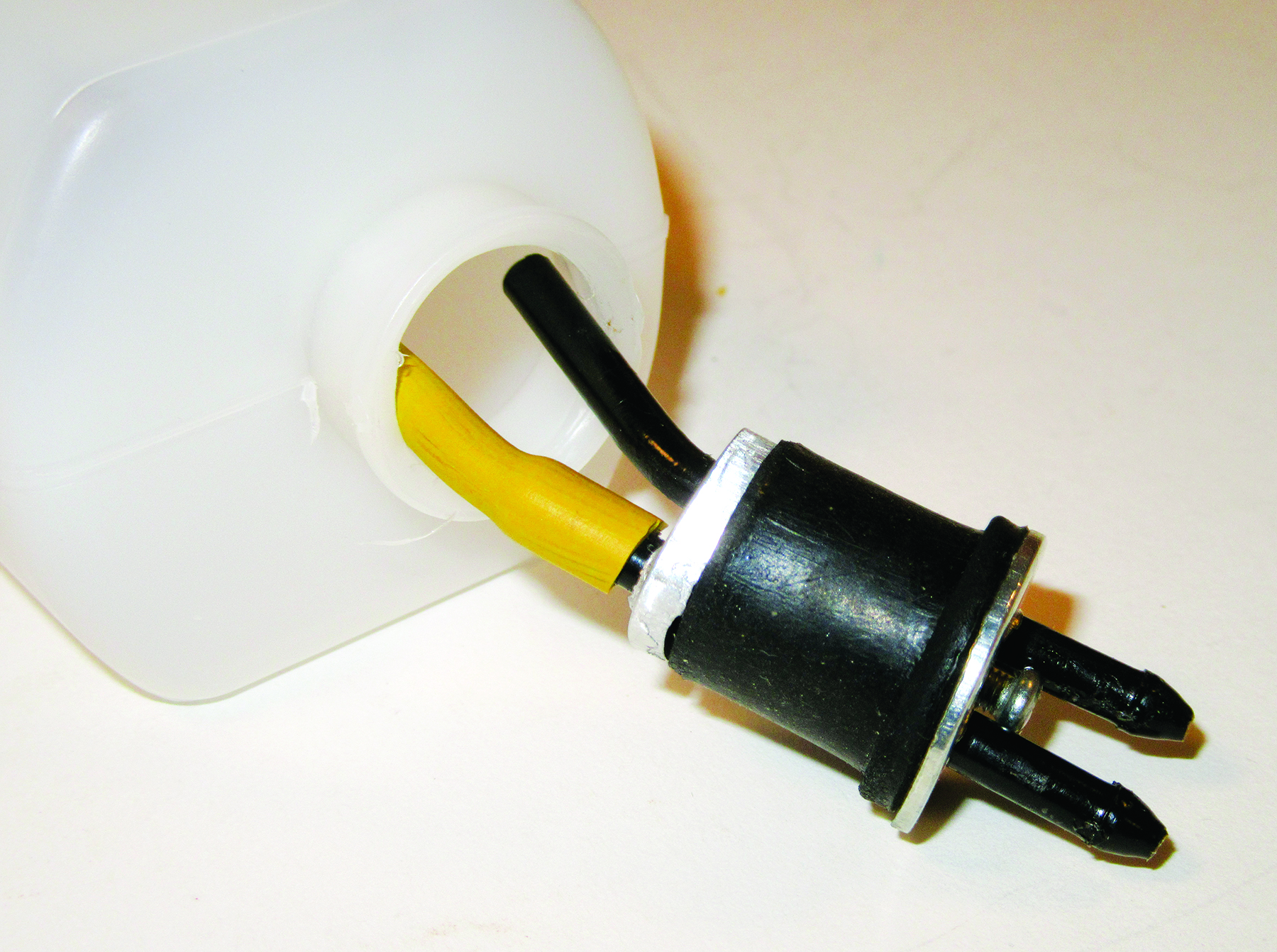

Check the opening of the tank to see if there’s any sharp flashing current. This might lower into and harm the rubber stopper. If there’s, use a pointy interest knife to chop it away, producing a slight bevel on the internal edge. Cut a chunk of the ProFlex gasoline line to size in order that, whenever you slip it onto the outlet tube, it’s about half an inch shy of reaching the again of the gasoline tank. Slip the steel gasoline pickup “clunk” into the tip of the pickup line after which slip the stopper into place to verify the pickup line’s size. With the stopper pushed all the best way in, the clunk must be about 1/4 inch shy of hitting the again of the tank. If it touches the underside, take away the meeting and shorten the pickup line.

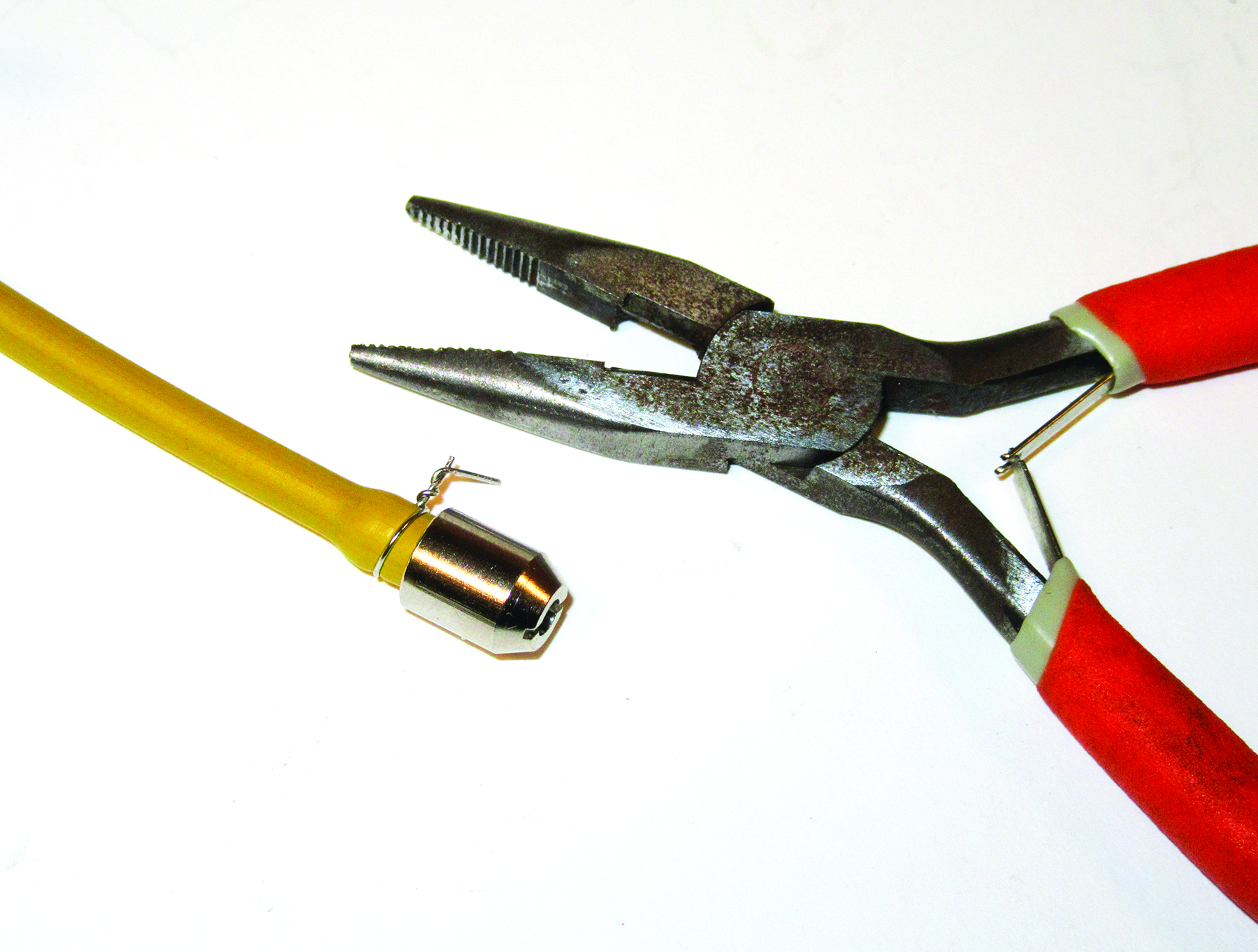

The ProFlex gasoline line comes with skinny items of wire that you simply wrap round and twist into place across the neck of the clunk. Using long-nose pliers, twist the wire tightly into place in order that it clamps across the line, then snip off the tip in order that about 1/8 inch stays. Since the outlet and bent vent tubes are made out of plastic, don’t use the clamping wire at these line attachments. Do not connect any gasoline tubing to the within of the vent tube.

The high of the tank is closest to the stopper and tank neck. Insert the gasoline line and stopper unit into the tank, and place it in order that the vent tube is on the high of the tank, then tighten the screw till the stopper is tightly safe within the neck of the tank. You shouldn’t be capable to twist or flip the stopper.

Before putting in the tank within the fuselage, lower two lengths of gasoline line about 6 to eight inches lengthy and slip them onto the gasoline outlet’s tubes. Add some tape to the vent line, and establish it with a “V” to assist forestall attaching the gasoline line incorrectly to the engine.

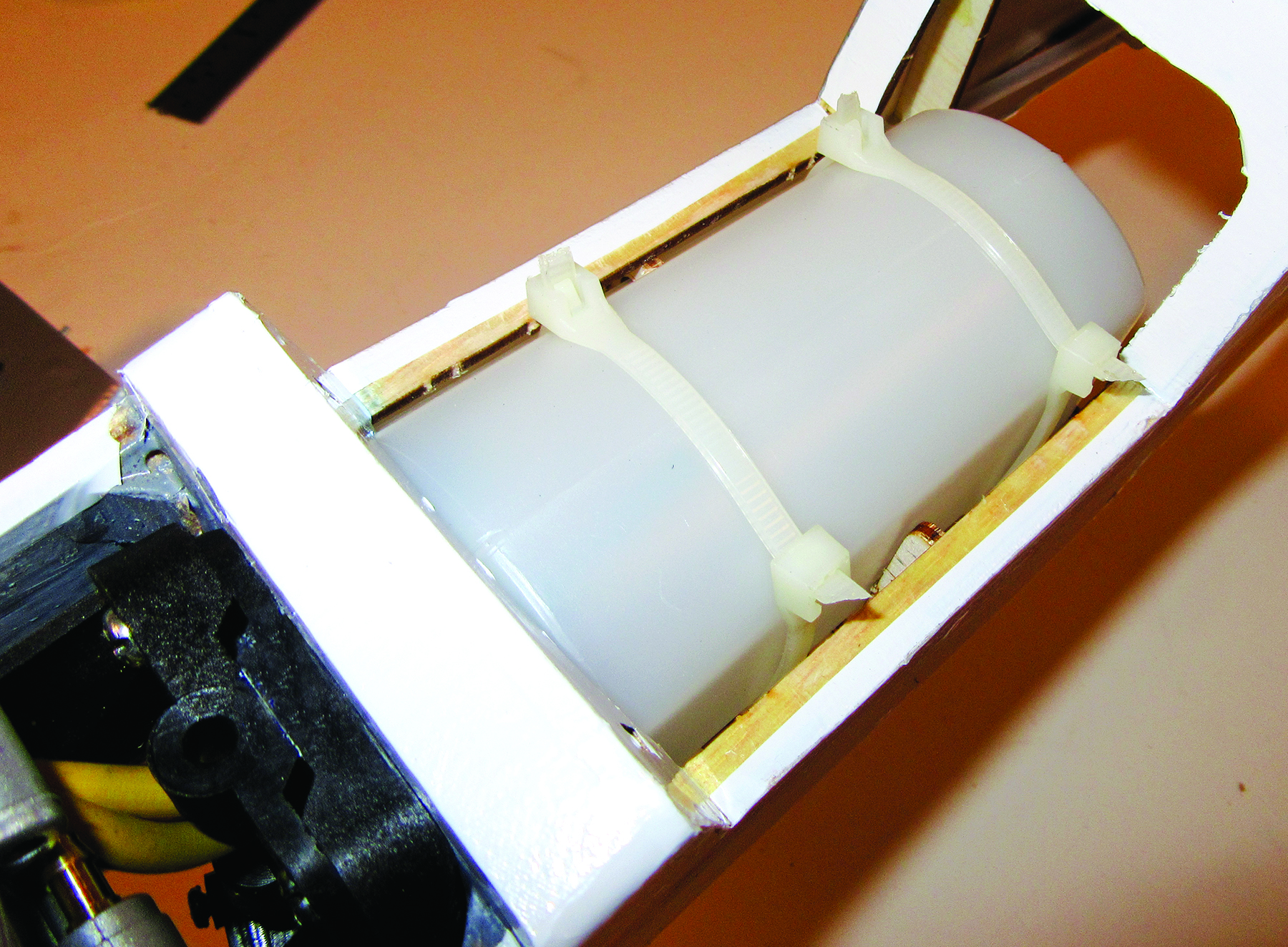

To set up the gasoline tank within the fuselage, loop two heavy-duty cable tie-wraps beneath the fuel-tank tray by way of the aspect notches in order that the ends prolong out of the fuel-tank compartment.

Slip the tank into the fuselage, and push it again in order that the entrance can clear the entrance of the hatch opening. Insert the 2 gasoline strains by way of the opening within the firewall, and pull them out as you slide the gasoline tank ahead. The neck and stopper of the tank suits into the firewall opening. Add a second tie-wrap to every of the opposite two, and tighten them in order that they maintain the tank firmly into place.

Snip the ends off of the tie-wraps, then trim away some materials from the underside of the hatch cowl in order that it clears the tie-wraps. The hatch cowl is held in place with a spring-loaded latch.

Allow about 2 inches of extra size and lower the fuel-supply line to size, and slip it onto the gasoline becoming on the again of the engine.

Install the muffler on the engine, securing it with two black machine screws and lock washers, and join the vent line to the muffler’s stress becoming, additionally permitting a few inches further size.

To full the power-system set up, all you must do is set up the included spinner and a Top Flite 9 x 5 Power Point propeller. The gap within the spinner backplate must be enlarged barely in order that it slips over the engine’s prop shaft with little to no play. Place the backplate in opposition to the engine’s thrust washer and the slip the propeller in place, adopted by the prop washer and prop nut. Tighten the prop nut down snugly, then give it one other quarter flip to essentially tighten it into place.

There are two molded-in prop guides within the channel across the backplate, which the lip of the spinner entrance suits into. The propeller must be positioned in between these guides in order that the blades match within the spinner cutouts. Position the entrance of the spinner in place after which screw it to the backplate with the 2 2mm x 1/2-inch screws.

RADIO INSTALLATION

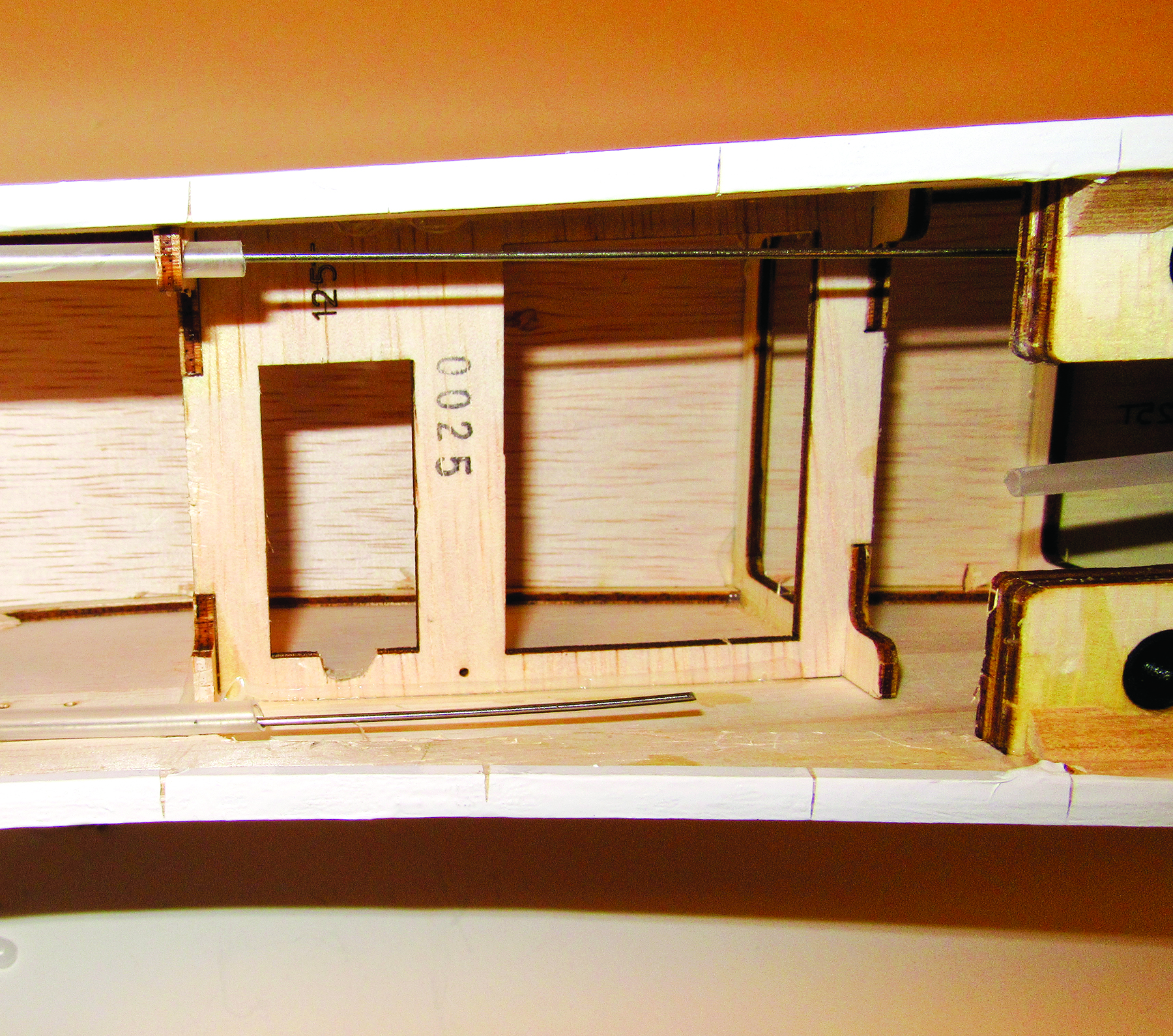

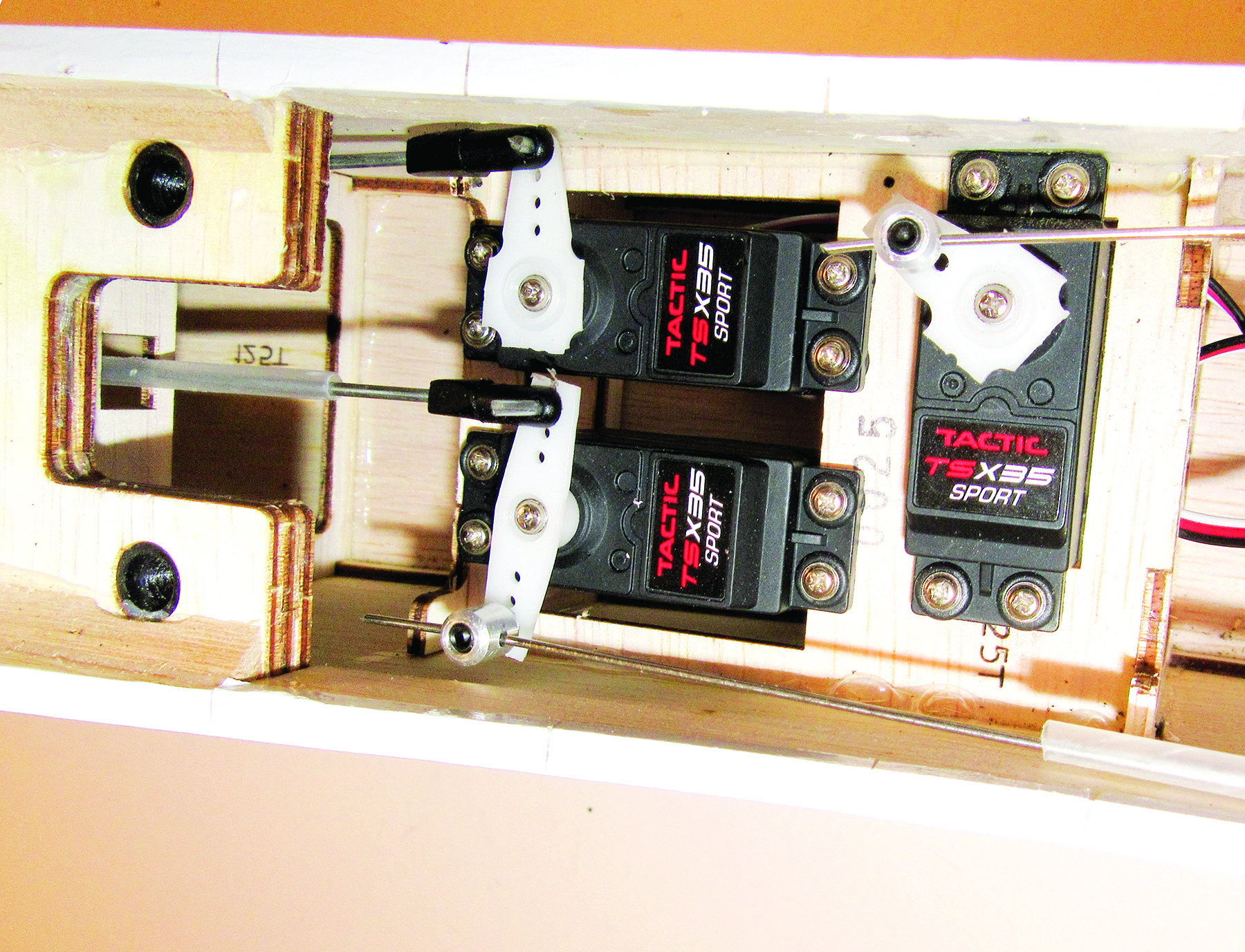

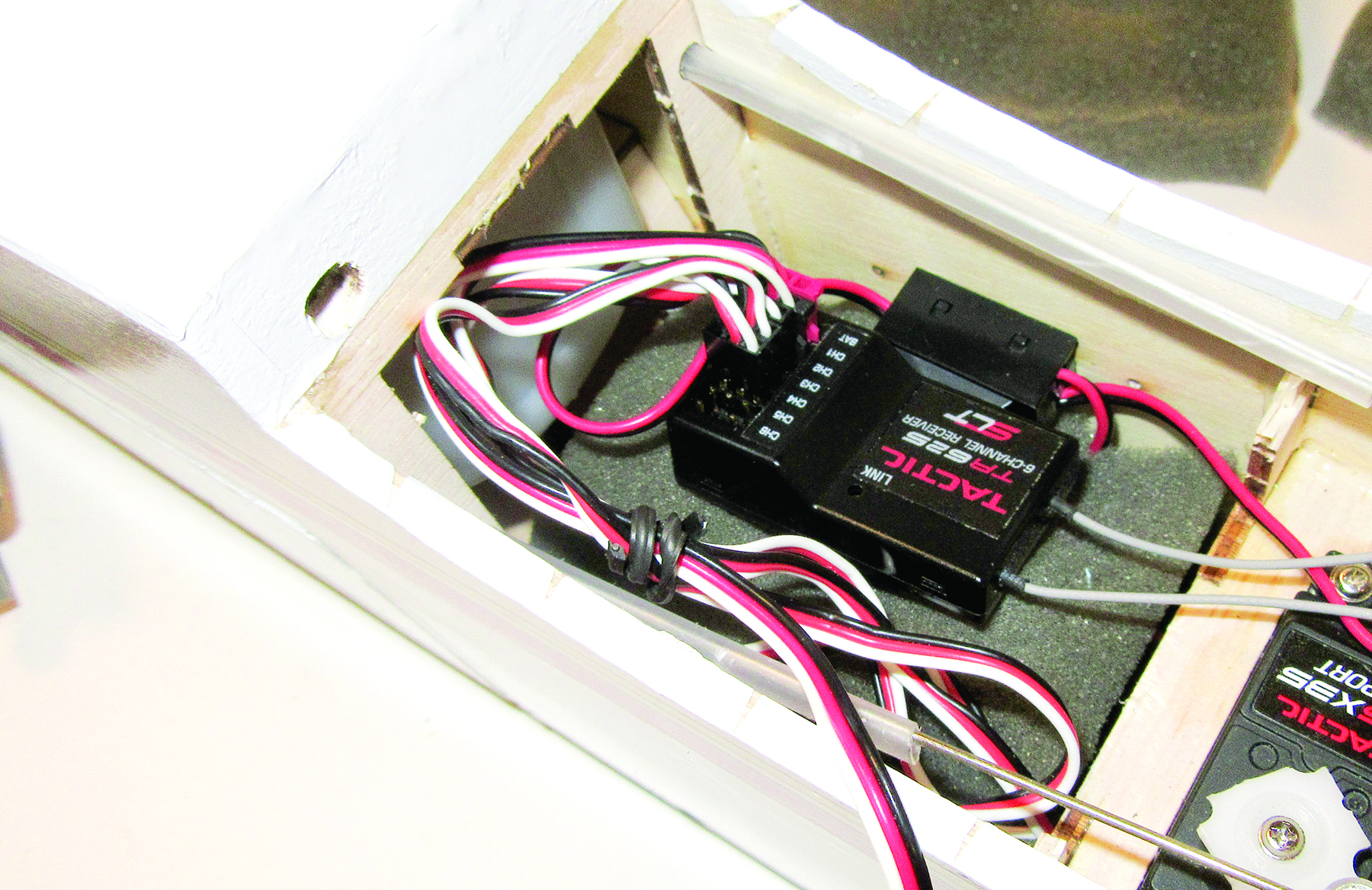

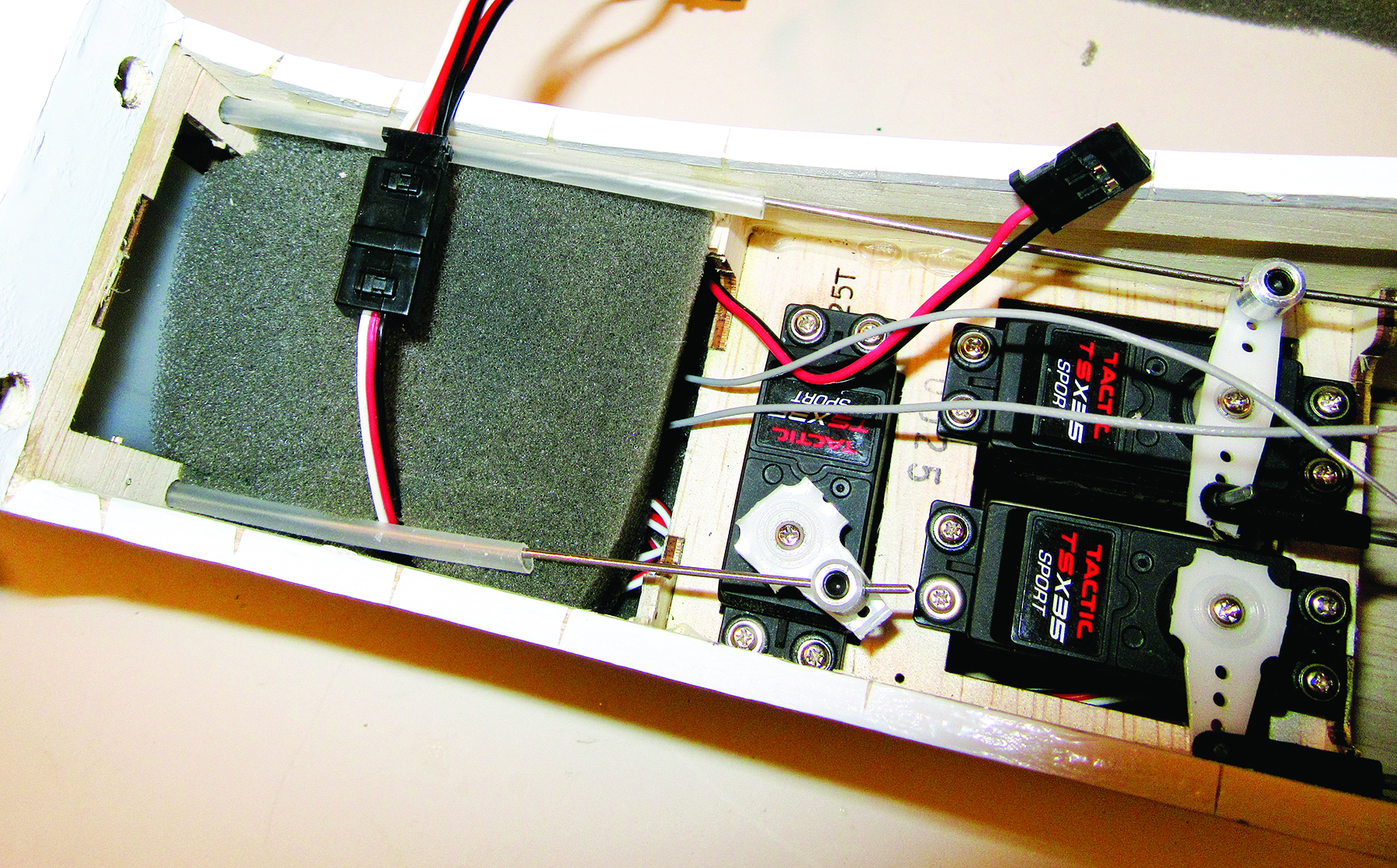

The subsequent factor to deal with is the set up of the management linkages for the elevator, rudder, and throttle, together with their servos and the remainder of the radio gear. Again, as we talked about within the final concern, all of the grommets and brass inserts should be put in appropriately within the servo-mounting tabs. Plug the servos into the receiver, and energy up the transmitter and receiver to heart the servo output shafts. You also needs to jot down which servos hook up with which receiver ports. With the Tactic TTX650, the aileron lead mates with port 1, the elevator plugs into port 2, the throttle goes into port 3, and port 4 is for the rudder. Once that is finished, we’ll set up the servo arms after we work out the management linkages and attachment factors.

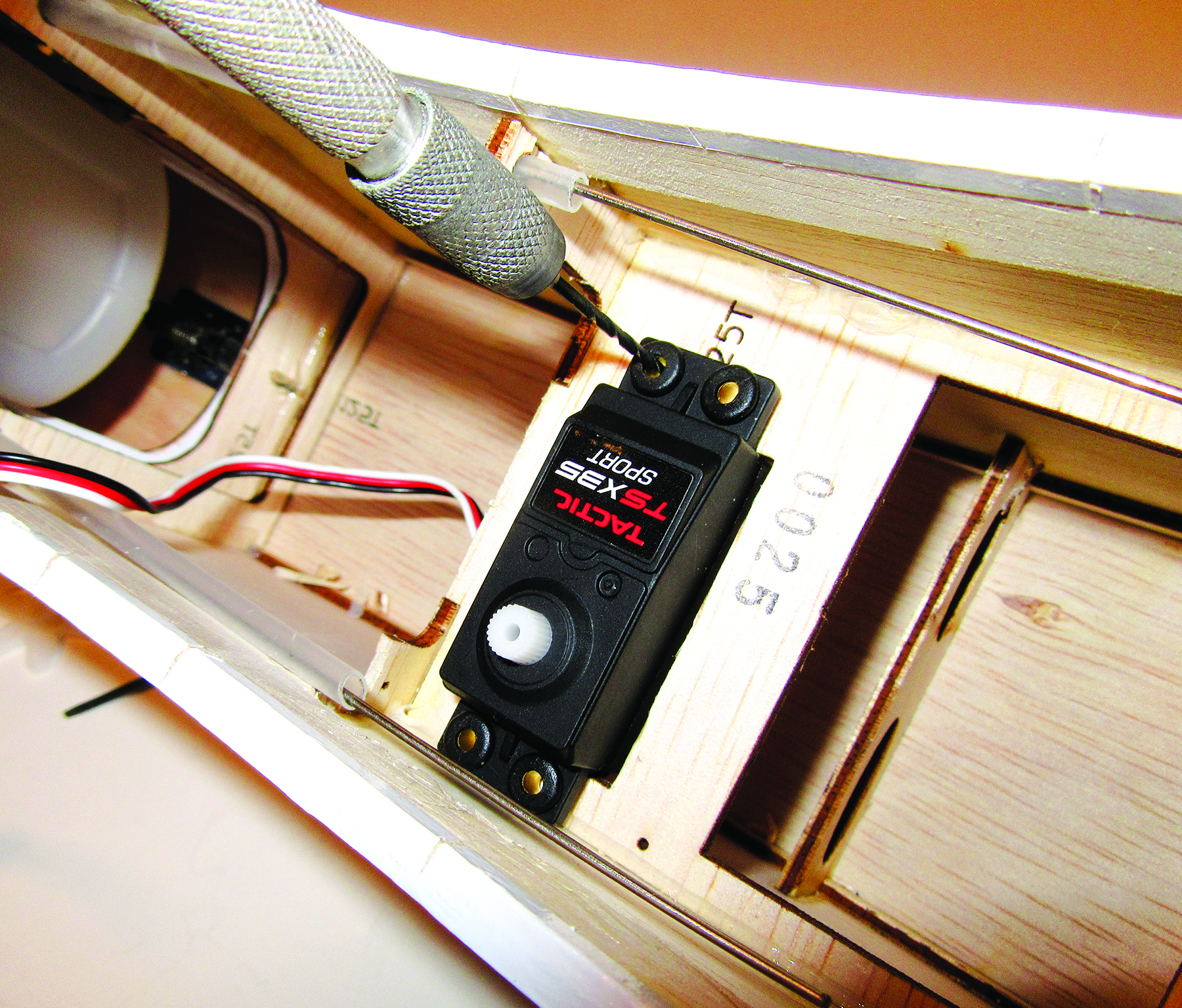

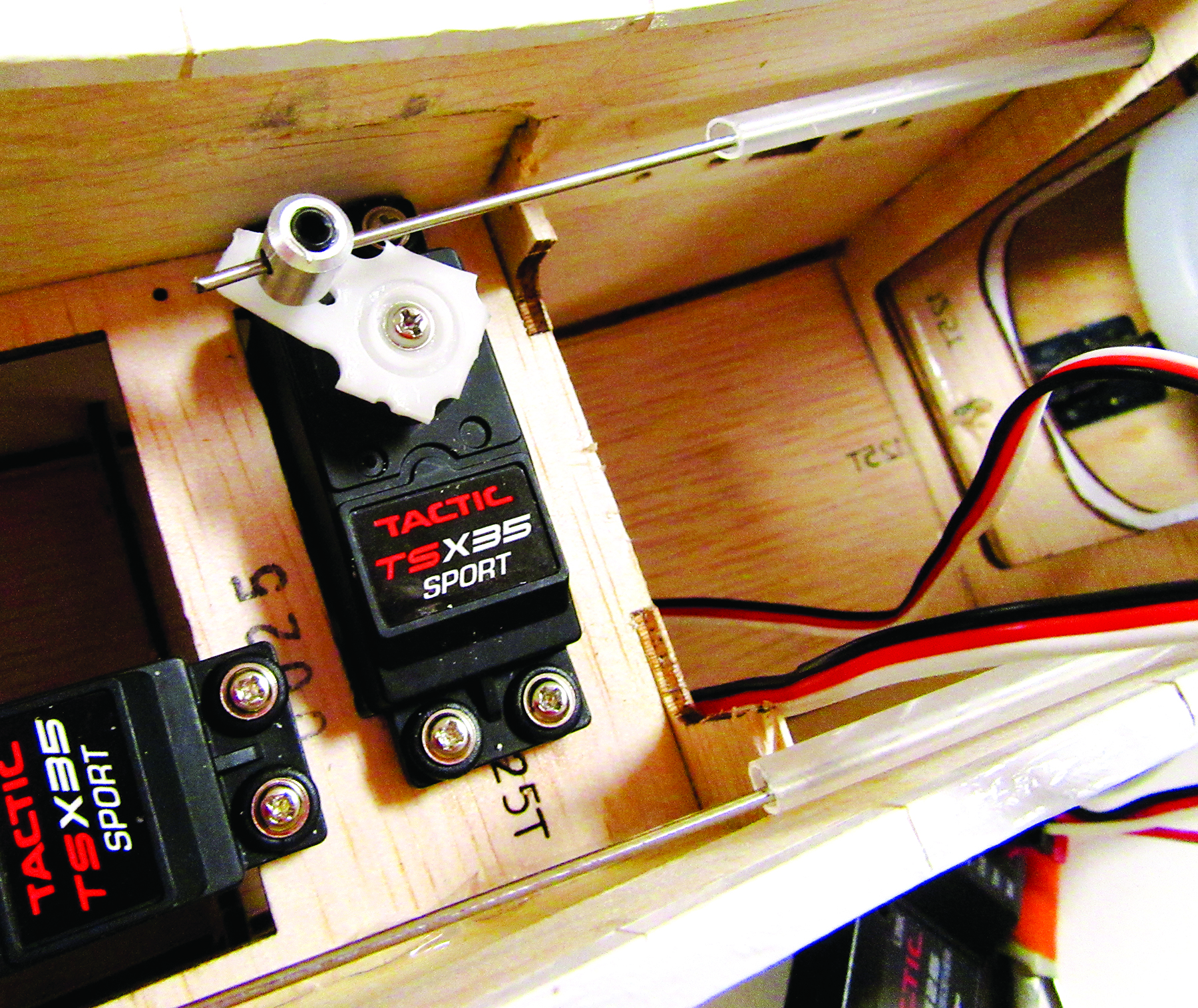

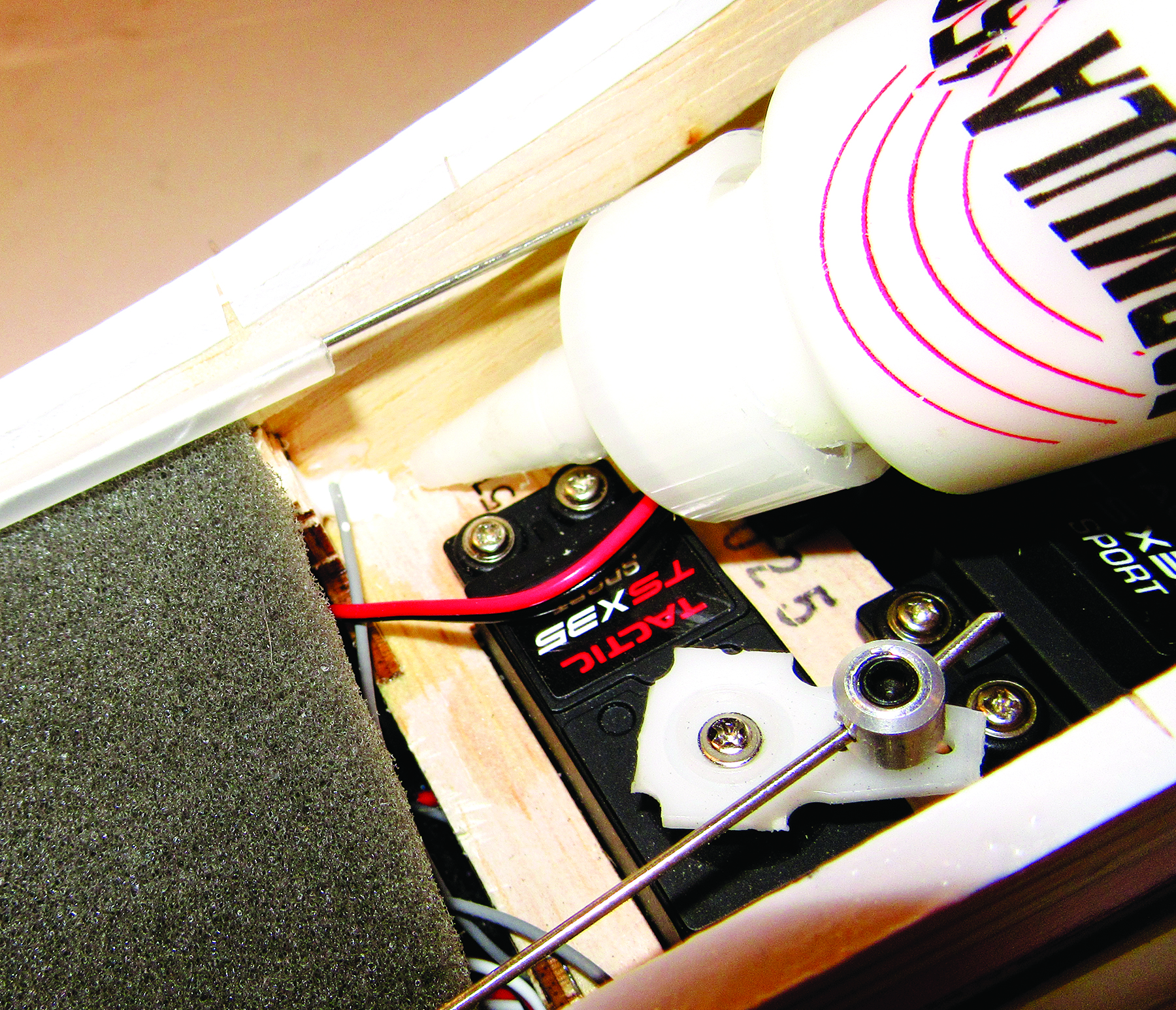

SERVO INSTALLATION

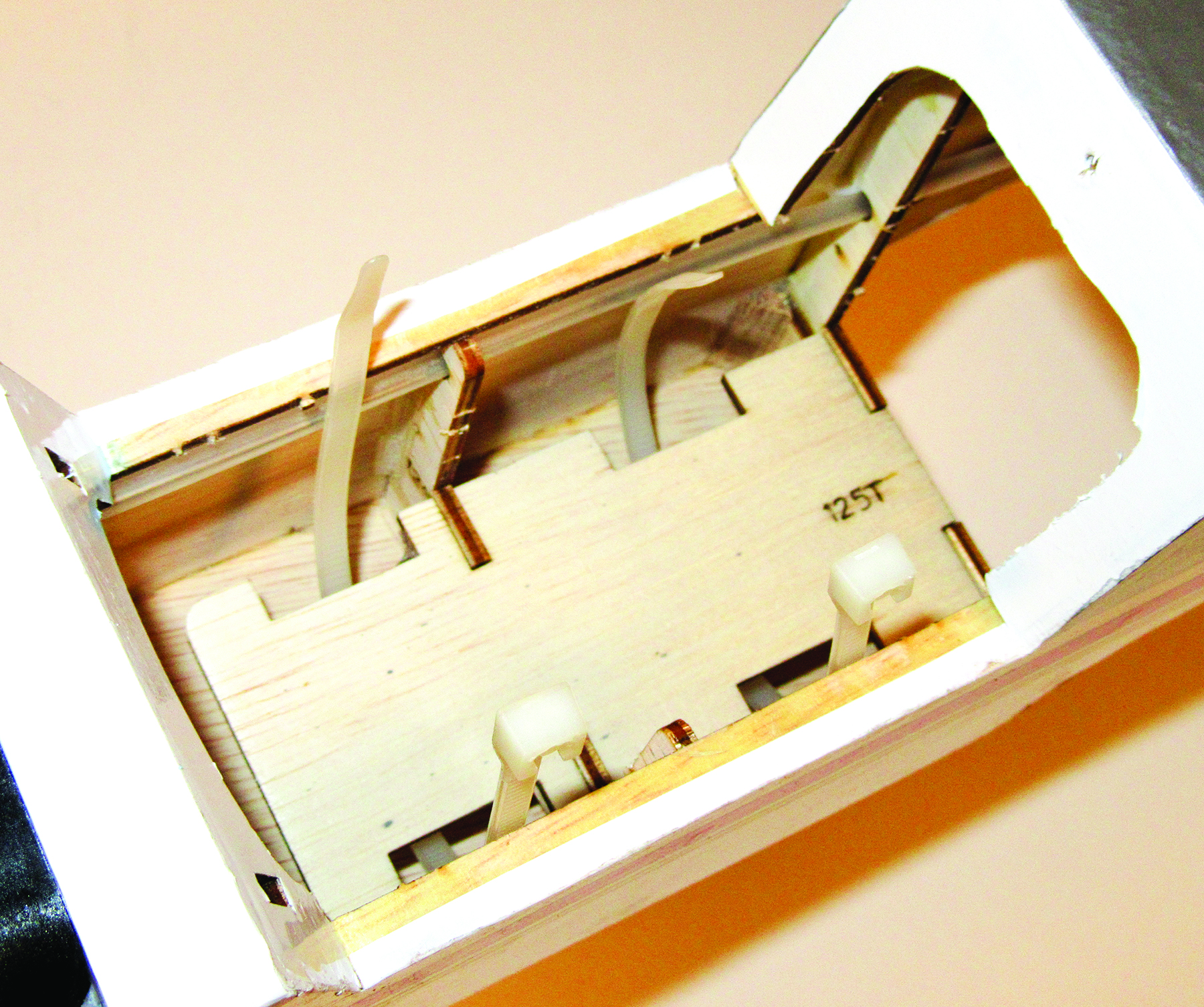

Before putting in the servos it’s a good time to put in the rudder and elevator management horns and the wire pushrods. You must lower away the masking from the information tube exits so you may slide the pushrods into place. Screw the clevises to the threaded ends of the wire pushrods and you might be able to go. Inside the radio compartment there’s a servo tray glued into place. Using the instruction booklet as a information, place the servos as proven. I discover that including one servo at a time after which including its management linkage is the best option to work within the confines of the slim radio compartment. You take away the wing after which work by way of the open wing saddle.

I began with the sideways-mounted throttle servo as it’s a tight match and the tray wants a bit of trimming to clear the servo leads. Using a pointy interest knife, notch the servo opening as proven; this enables the wires to be routed beneath the tray with out pinching.

While holding the servo in place, use a 1/16-inch drill bit and drill by way of the servo grommets into the tray; screw the servo into place.

Center the rudder, and mark the pushrod for the servo-arm gap location. Bend the pushrod 90 levels at this mark, then connect it to the servo arm with a pushrod keeper.

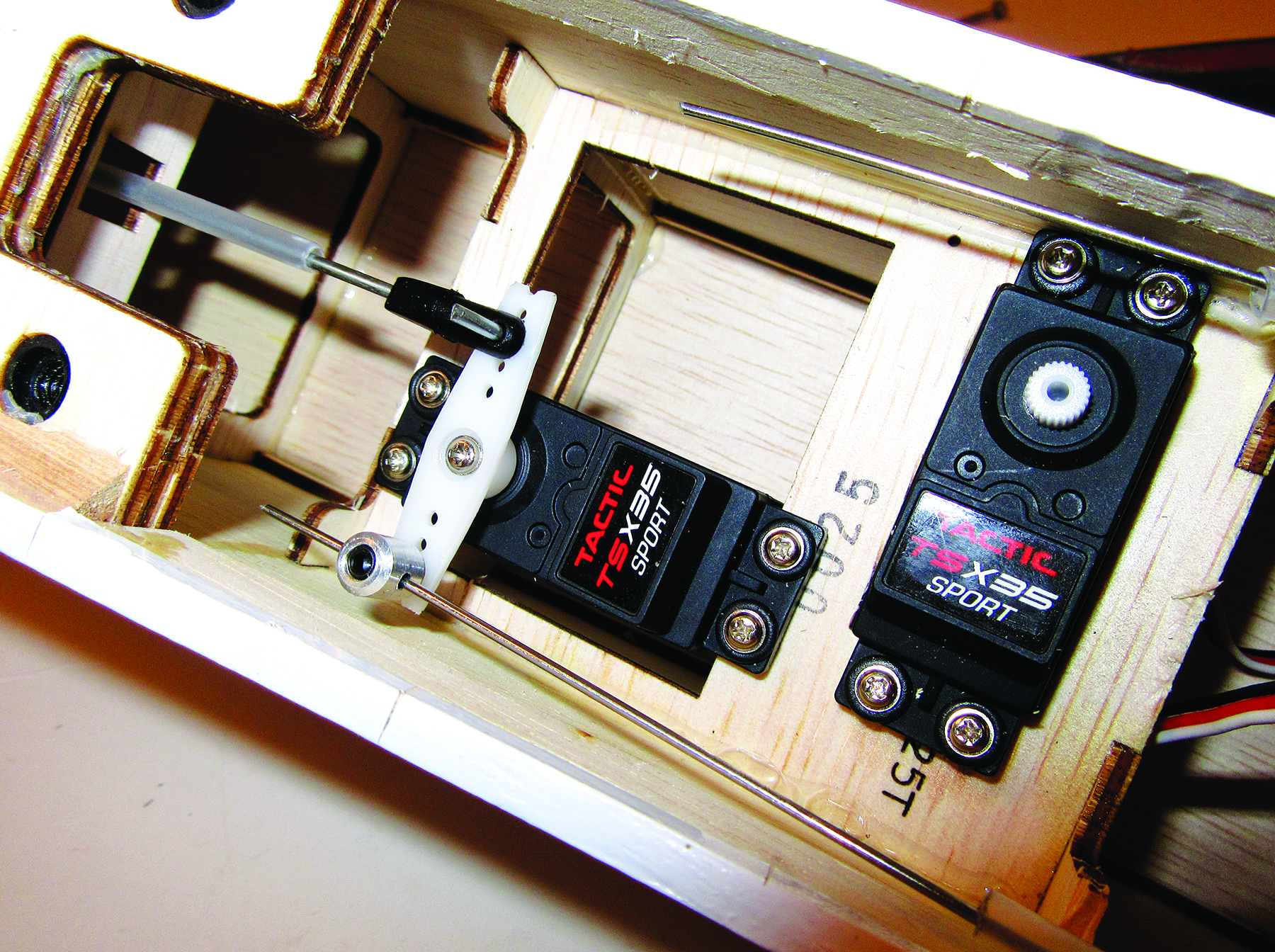

Next, set up the rudder servo. You want to make use of the twin servo arm because the servo will management each the rudder and the nosewheel steering. Position the rudder servo in order that the holes within the servo arm align with the wire pushrod and the steering linkage for the nosewheel. While holding the servo in place, drill the holes and screw it into place. For each the throttle and the nosewheel steering linkage, threaded linkage connectors have for use. These have threaded studs and locknuts used to connect them to the servo arms.

You must enlarge the holes within the arms utilizing a 1/16-inch drill bit. Insert the stud within the arm, and with one locknut above and beneath the arm, use two long-nose pliers to tighten the connector into place. There are holes within the sides of the connectors that settle for the management linkages, and on the highest is a setscrew to safe the linkage into place. Center the servo, then regulate the nosewheel in order that it’s centered pointing straight forward; tighten the setscrew.

TECH TIP 2

With ARF fashions just like the Sonic, the servo trays are sometimes made out of softer wooden, similar to laminated balsa or gentle plywood. After you drill the servo-mounting screw holes, add a drop of skinny Zap CA to every gap. This will soak into the wooden and harden it the place the holes are drilled, giving the screws a stronger “bite,” which helps forestall the screws from stripping out the holes.

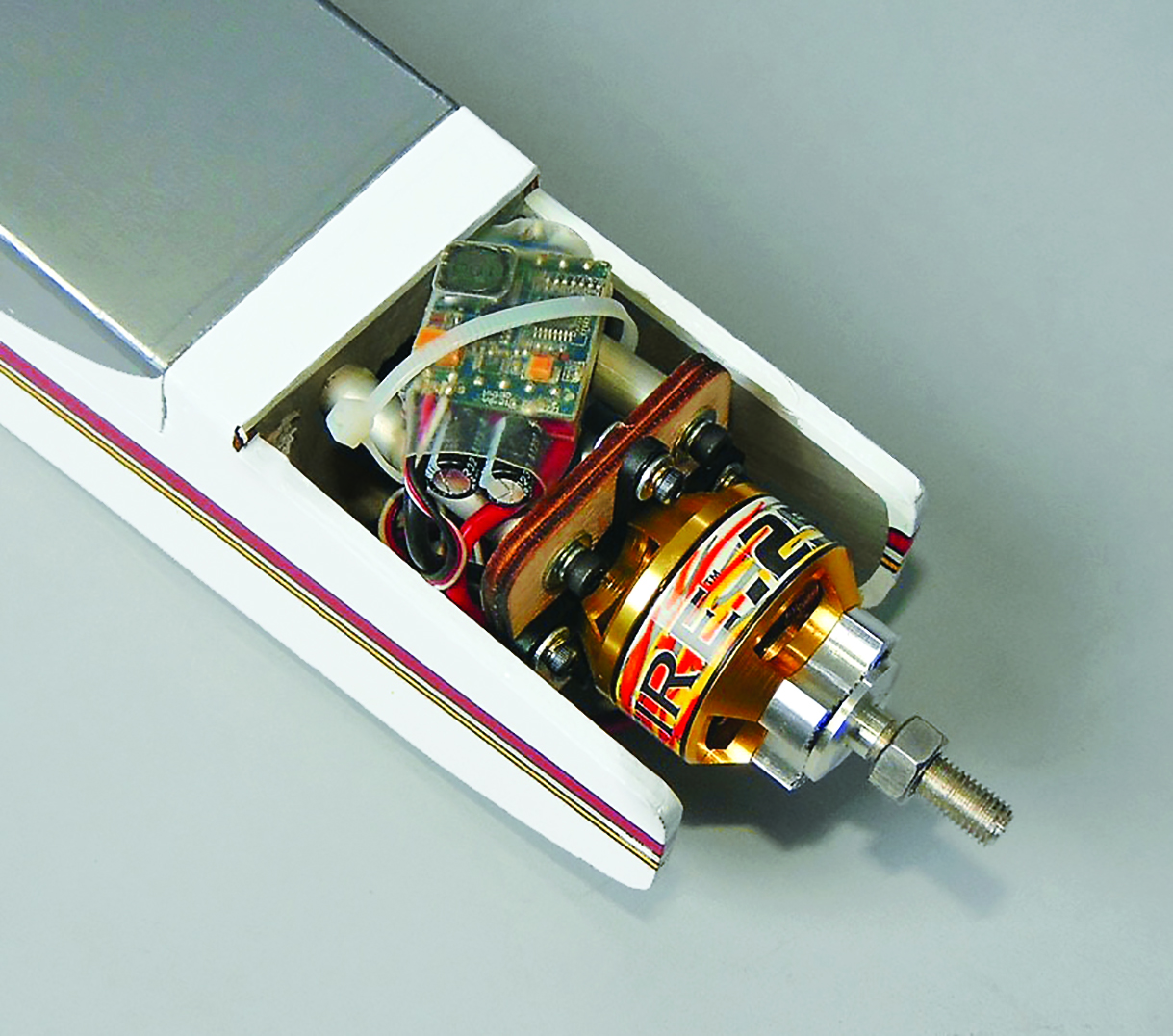

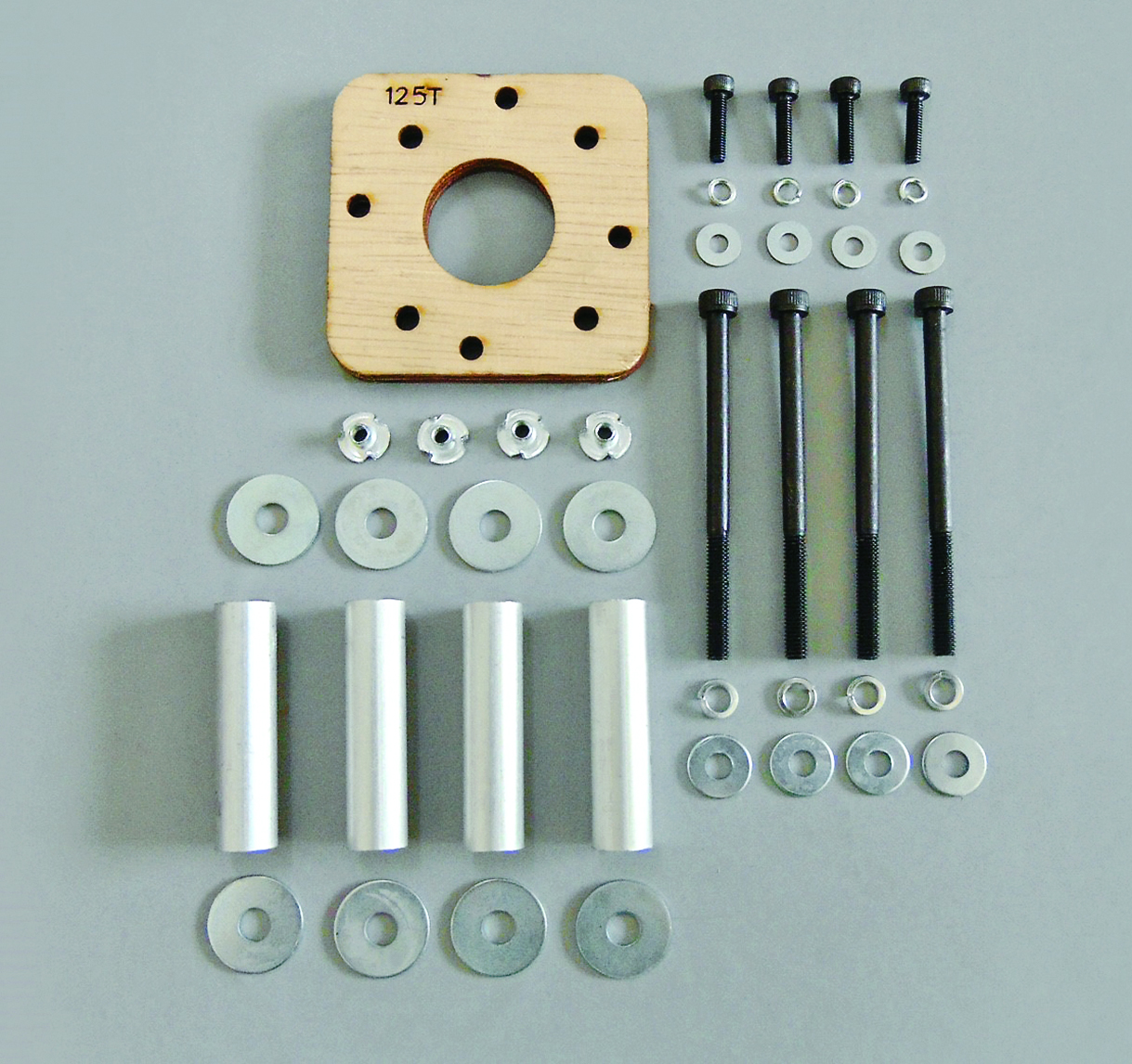

ELECTRIC POWER

As the Sonic is designed to make use of both a glow engine or an electrical energy system, listed below are a few pictures to point out the e-power setup. The mannequin additionally comes as a part of the {hardware} bundle, with all the required components to put in an electrical motor. These embody all of the aluminum standoffs and screws wanted to connect the electrical motor. For the Sonic, an ElectriFly RimFire .25 is beneficial together with an ElectriFly 30A to 40A velocity management. The wiring is simple as it’s a plug-and-play and the velocity controller is connected to the standoffs behind the mannequin, out within the breeze for plentiful cooling. Since the gasoline tank is just not wanted, the tank tray is the place the 3S 2000–3000mAh LiPo flight pack is put in. To choose the correct e-power propeller, verify the directions that include the motor.

THROTTLE LINKAGE

The throttle servo is completely different from the remainder of the servos because it doesn’t relaxation within the centered place. To set up the throttle linkage correctly, you first have to make use of the transmitter and produce each the throttle stick and the throttle trim right down to the idle positions. Typically, the throttle arm on the carburetor has a comparatively quick journey, so you need to use a brief servo arm, or you should use the second-to-last internal gap within the arm because the attachment level and lower the servo arm in order that it clears the aspect of the fuselage.

Install the linkage connector after which insert the throttle pushrod. Pull the linkage again in order that the carburetor closes absolutely, and tighten the setscrew on the high of the connector. Move the throttle stick all the best way ahead and verify the motion of the carburetor’s throttle opening. It must be absolutely open with the stick all the best way ahead; if it isn’t or if the pushrod strikes too far and bows barely on the full-power place, you may regulate the servo journey later in order that there is no such thing as a binding within the linkage.

The elevator servo and linkage is the following one to do, and it’s finished in the identical manner because the rudder servo. Position the servo, utilizing the arm as a information in order that it doesn’t contact the fuselage aspect, and drill the holes and screw it into place. Center the elevator place, align the pushrod with the servo-arm attachment gap, and mark the pushrod wire. Bend 90 levels on the mark, and fix the pushrod to the arm utilizing the keeper to safe the linkage. At this level, you may activate the radio system and verify the motion of the servos and the management surfaces and linkages. There must be no binding all through the servo arms’ motion.

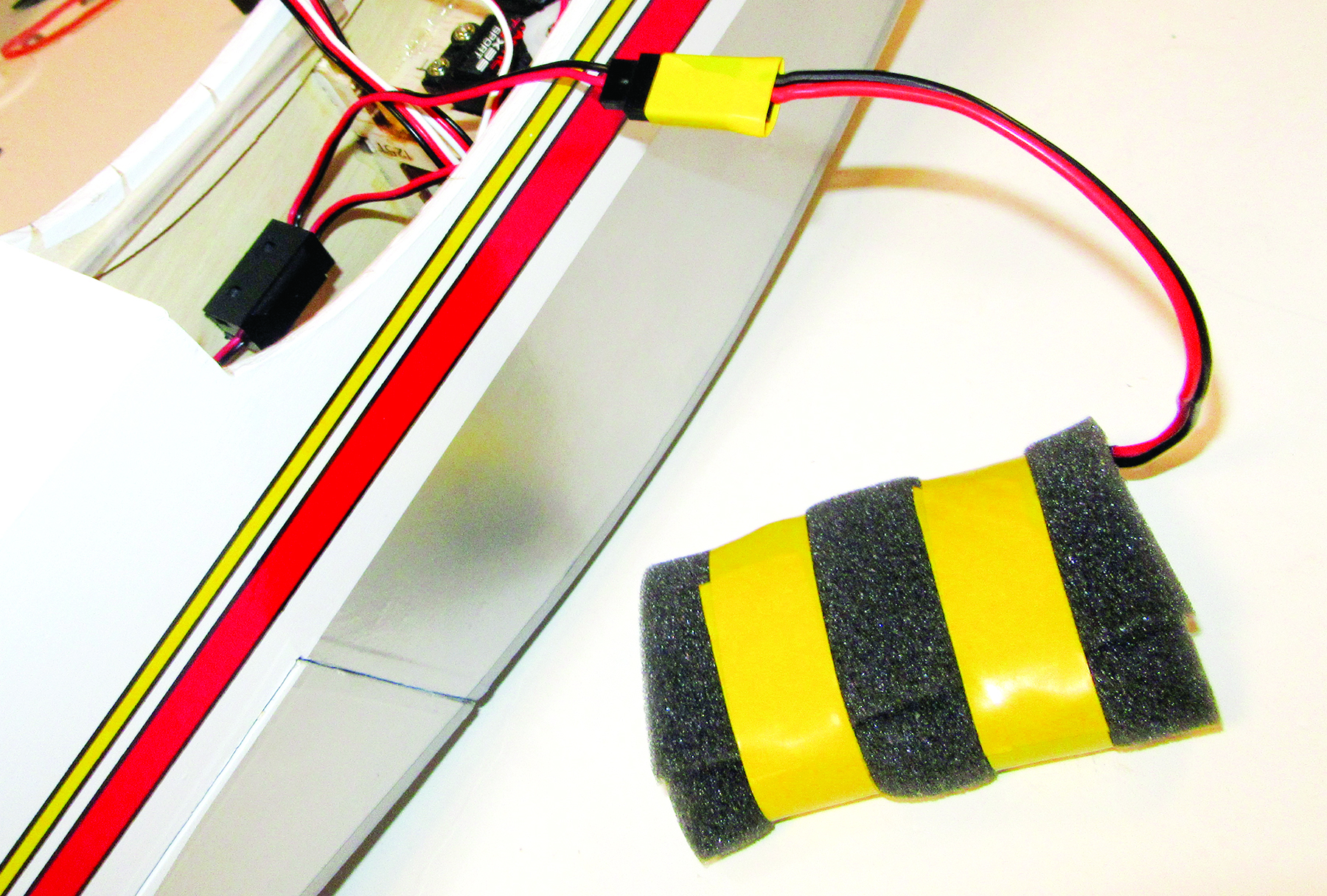

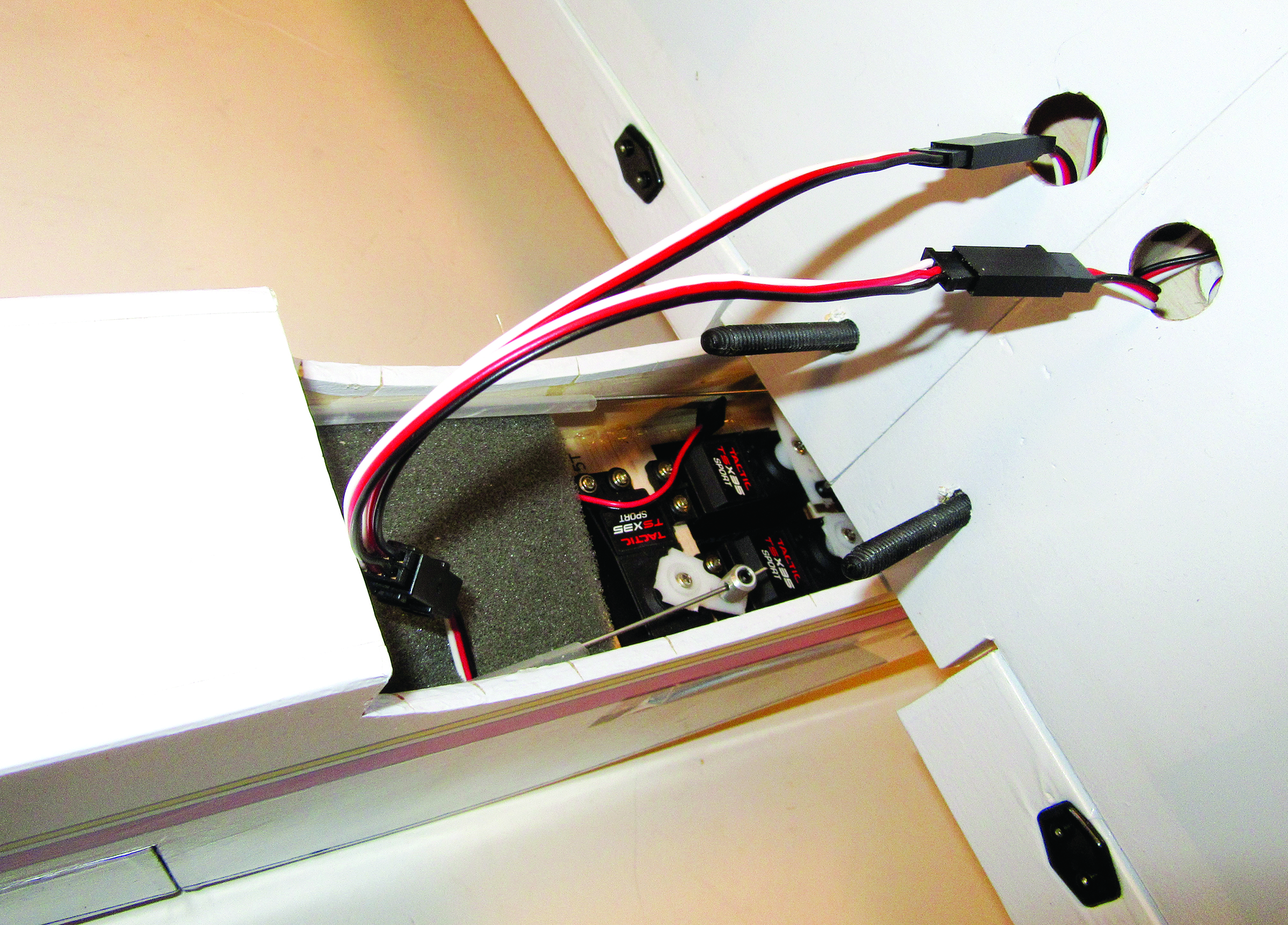

RECEIVER AND BATTERY PACK

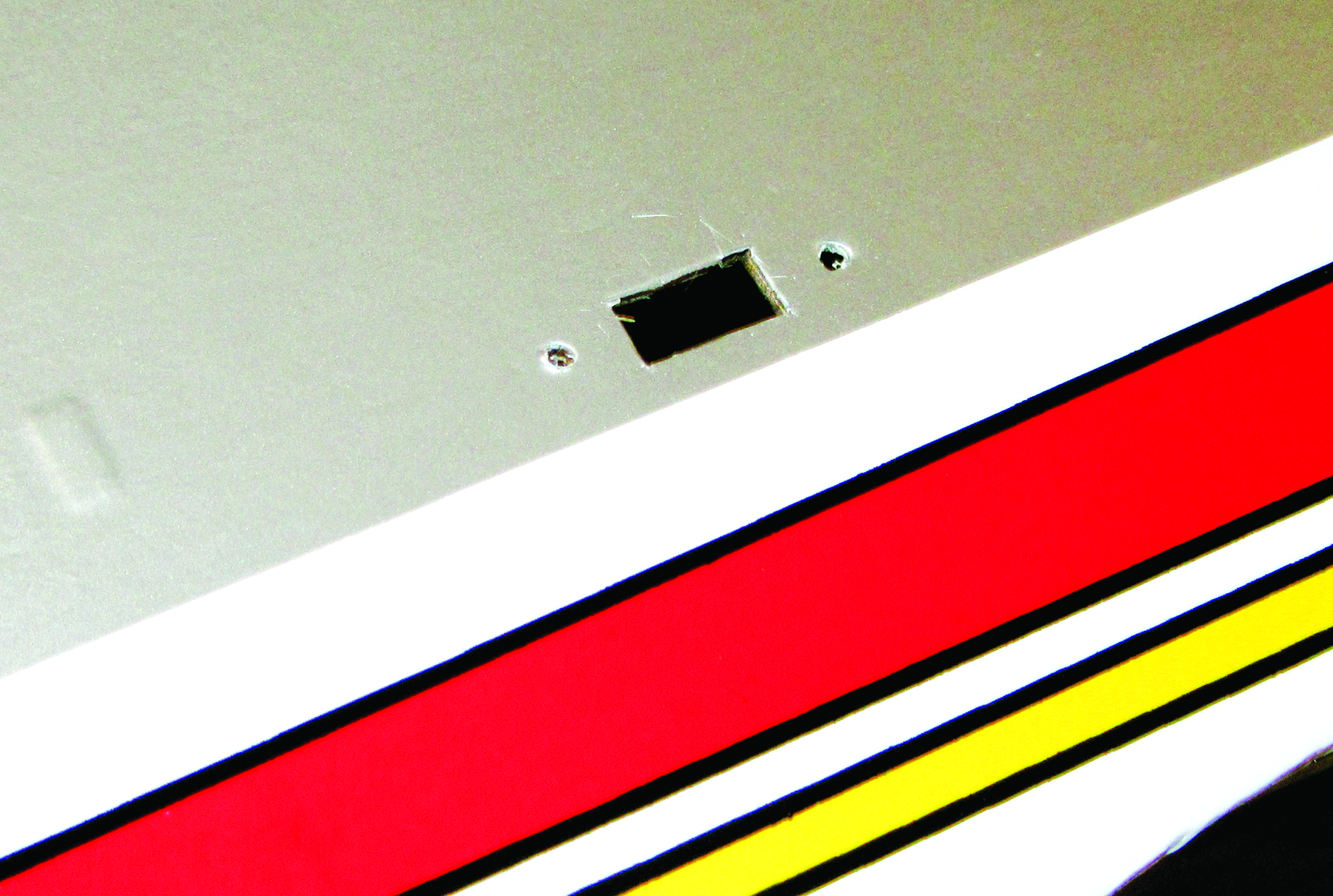

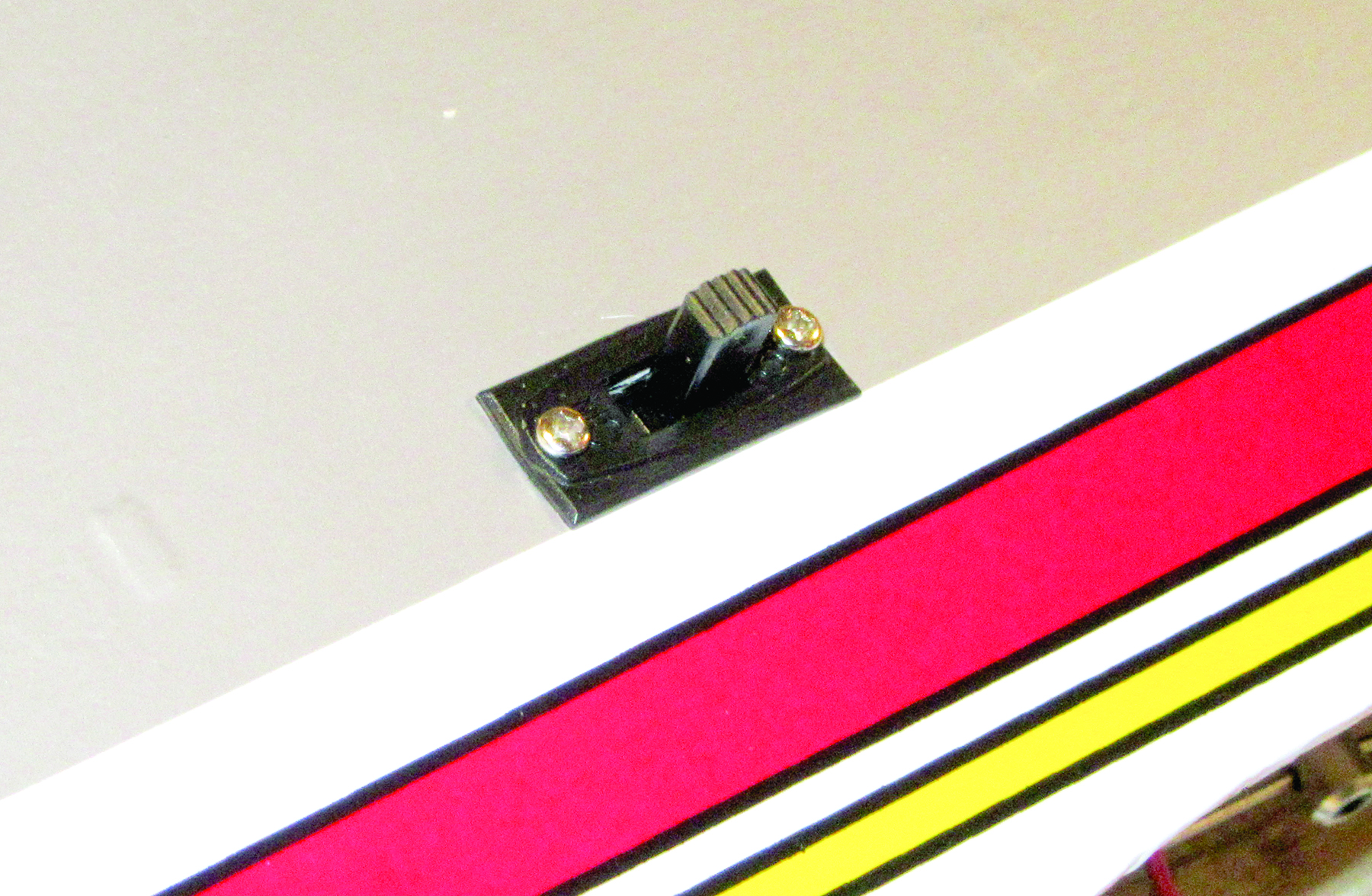

There is a sq. opening within the aspect of the fuselage, and that is the place the radio energy change is put in. There are additionally two holes on the sides of the opening, and you’ll pop them open with a small screwdriver.

Remove the change cowl, and place it with the “off” place dealing with the rear of the airplane. Insert the change harness from inside, and screw the change and change cowl collectively.

For a little bit of security throughout flight, use a chunk {of electrical} tape and safe the battery pack’s result in the change harness feminine connector. This will forestall vibration from inflicting the wires to return aside. Wrap the battery pack with 1/8-inch-thick packing foam, and safe it in place with two lengths of tape. Place the pack within the backside of the radio compartment in entrance of the servo tray. Check all of the servo leads in addition to the switch-harness connector, ensuring they’re correctly and fully plugged into their receiver ports.

Place a 1-inch-thick piece of packing foam over the battery pack. This piece must be oversize by about half an inch in order that it stays in place when inserted into the radio compartment. Position the receiver within the heart of the froth. Using one of many wire wraps that comes with the brand new servos, collect and bind the servo leads collectively. This retains the radio set up neat and helps forestall any of the servo leads from getting chafed by the servo linkages.

Place one other piece of 1-inch foam over the receiver, ensuring that the twin antennae, the charging plug, and the aileron Y-harness are all accessible.

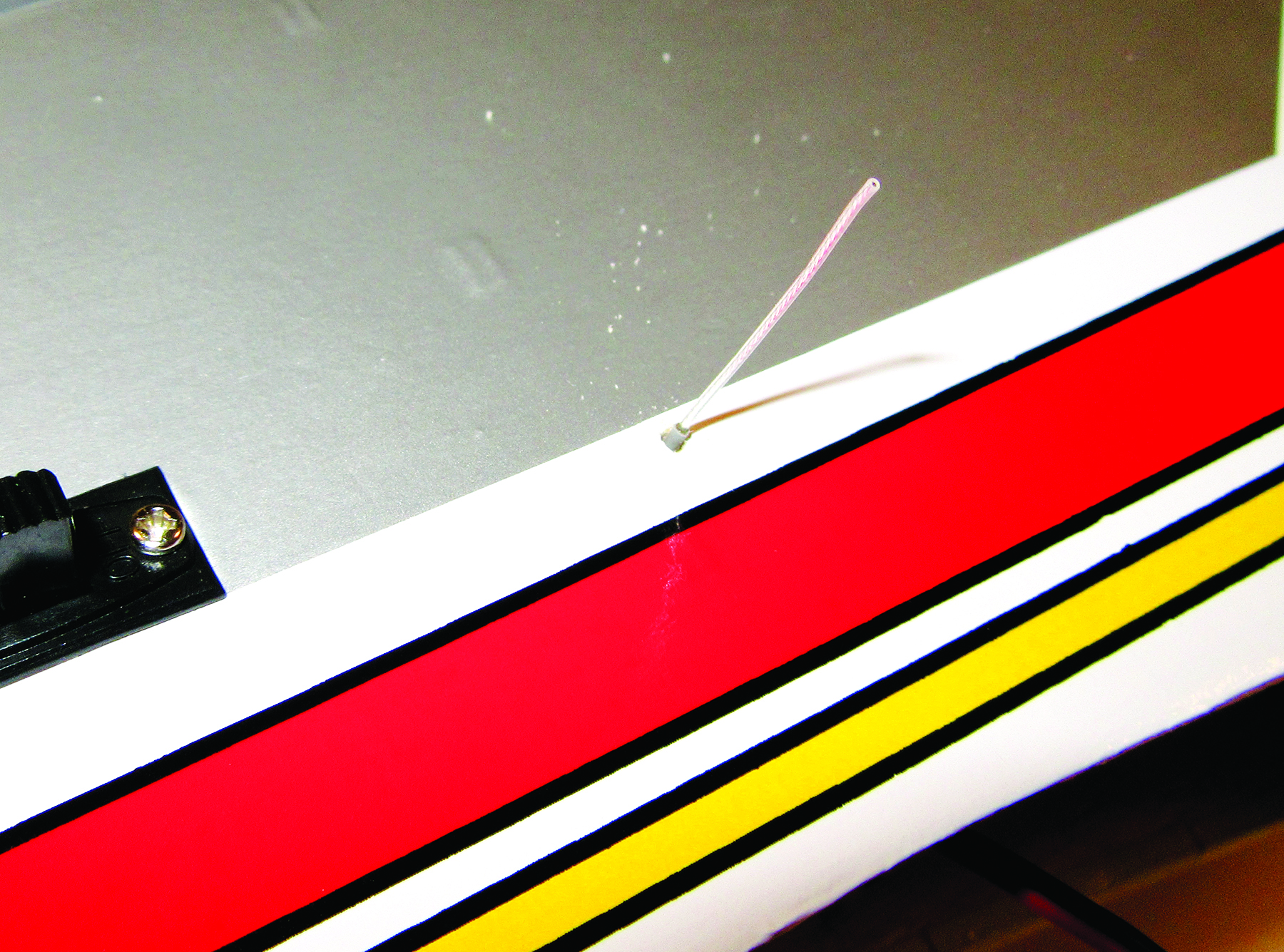

There are two antenna leads with the Tactic receiver, they usually should be put in in order that the 2 outer ends are positioned 90 levels to one another. The simplest way to do that is to drill small holes within the sides of the fuselage and information them by way of to the skin. Pull one all the best way out, and tape it to the skin of the fuselage in order that it factors to the tail. Be positive to not have any rigidity on the antenna the place it’s linked to the receiver.

For the opposite antenna lead, insert it within the gap on the opposite aspect of the fuselage in order that solely the very finish of the antenna is uncovered and it factors 90 levels from the fuselage aspect.

Use just a few dabs of Zap Canopy Glue to safe the antenna leads the place they undergo the holes, and let dry. This glue stays versatile when cured and holds the antenna leads in place, however it’s straightforward to take away in a while.

FINAL ASSEMBLY

All that’s left to do is to attach the aileron leads popping out of the wing to the Y-harness after which connect the wing to the fuselage. Make positive you push the wire leads again into the holes within the high of the wing, and be certain to not pinch the wire leads between the wing and the wing-saddle sides. When every little thing is aligned, tighten the 2 wing attachment bolts. You at the moment are finished constructing your Sonic ARF sport airplane.

Bottom Line

So that’s it, our Sonic is able to go. All that’s left to get it able to fly is to interrupt within the engine, and make the ultimate radio and servo changes with the Tactic radio’s programming. But that’s one other story. The duties and methods proven on this article are relevant to most any ARFs accessible right now. If you’ve gotten any questions, we’d love to listen to from you. Email us at MAN@airage.com.