OVER THE TOP MUSTANG MAKEOVER — THE UPS AND DOWNS OF MODIFYING A GIANT-SCALE WARBIRD

An exquisite article by our outdated and late good friend Frank Tiano. Enjoy and Happy New Year!

Yea, it’s simply me and the chook. The Hangar 9 Mustang ain’t small, and it flies nearly as good because it seems.

I promise that you’ll take pleasure in this text. After discussing article concepts with the MAN editors, we agreed that this shouldn’t be a assessment of an ARF as there are simply too lots of them already. Nor ought to or not it’s an entire package construct (which I really love) as a result of they’re few and much between, now that producers don’t make kits anymore. This article is an entertaining, fun-to-read story of my improve of a preferred ARF warbird: the attractive Hangar 9 P-51 Mustang.

My concept was to take the favored Hangar 9 P-51D Mustang and provides it an entire makeover, utilizing nothing however the most interesting of upgrades within the course of. Best of all, when accomplished, the challenge would produce an ideal airplane excellent for all of the warbird occasions by which I take part. The Hangar 9 Mustang spans 89 inches, has 1,420 sq. inches of wing space, and requires a completed weight of about 28 kilos. I do not know what how a lot it may cost at your favourite pastime store, however the instructed retail value is $939, with a median avenue value of about 800 bucks. Have I acquired your consideration?

CLEARING THE BENCH

When the Mustang arrived, the very first thing I did was clear a bench within the workshop and requested my good friend John Banner to strip the iron-on ARF masking. He additionally strengthened areas that he thought wanted it, then completed all the airframe with 1.5 oz. fiberglass material and Z-Poxy Finishing Resin. While he was doing that, I seemed for an engine. I needed an excellent moose motor manner out of the extraordinary that might match into the engine compartment. I’ve a number of associates within the trade who distribute varied manufacturers of engines, and through the search course of, Michel, at AMR (Aircraft Modeler’s Research) in Canada, provided a brand new ZDZ 80cc inline twin-cylinder at a value that I merely couldn’t refuse. Michel warned me that there have been no mufflers accessible but, so I must fabricate by myself one thing that might match the P-51. Challenge accepted, I advised him to ship it. (And talking of AMR, you’ve simply acquired to take a look at its stock of engines and kits!)

LANDING GEAR

Anyway, someday quickly after that, I spoke with Dennis Crooks at Robart Manufacturing and requested if the corporate may need a set of air-operated retractable touchdown gear for the Hangar 9 Mustang. He mentioned, “Not yet, we’re still working on them, but we do have the electric version.” I mentioned I’d be blissful to attend as a result of I’m not a fan of electrical gear—but. A couple of weeks later, the touchdown gear confirmed up, and it took lower than an hour to suit them into the wing. The landing-gear doorways had been one other story! There had been some severe challenges in getting them to shut—and keep closed—correctly, however Jimmy Prive, my latest store rat, labored it out with some small Robart air cylinders and bellcranks (see sidebar on p. 37).

ENGINE INSTALLATION

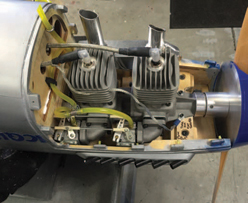

The most tough process turned out to be the set up of the ZDZ 80 twin into an space initially designed for one thing else, primarily the Evolution 60cc. But I used to be decided to make use of that ZDZ 80 twin! Before explaining how I did that, listed here are some particulars concerning the engine. It is a compact 80cc inline engine with two carburetors sharing throttle and choke linkages. The carbs sit on the facet of the engine, making it somewhat difficult to mount it in fashions with slender entrance ends. It is engaging in so some ways—look, workmanship, and the truth that it has a really lengthy snout and a low profile. It has a backplate mount, and the carbs sit farther to the rear than the mount. When it got here time to put in the ZDZ, we discovered that there have been bulkheads and items of motor mount from the airframe in the best way. Remember, this airplane was by no means supposed to be powered by a bit of equipment like this 80cc twin. The engine compartment was extra apt to carry comfortably a single-cylinder 55 to 70cc engine. Anyway, as I used to be pulling out what little hair I’ve left, Denny DeWeese, who was engaged on one other challenge in my store, advised me to cease whining, get misplaced, and depart him alone with it for a bit. A day or so later, he had the dual nestled in place, with correct reinforcements added, and advised me the set up was prepared for the carburetor linkage and muffler fabrication.

This exhibits the inventory masking stripped from the airframe.

Here, we see the mannequin because it exits the delivery field.

Here are all of the airframe elements glassed and primed, prepared to color.

CUSTOM EXHAUST

With such a confined space, the muffler needed to be customized made. I made a dummy muffler from balsa, made with precise notations the place the exhausts and mounting bolts had been wanted and despatched my sample off to the grasp, Al Young, at J-Tec, in Mooresville, North Carolina. In a matter of some weeks he despatched me a brand new muffler for my ZDZ 80. It match the slender confines of the Mustang’s cowl space completely! The throttle and choke linkages required some outdoors the field considering, however finally all of it got here collectively and operated easily. The radio set up was uneventful, simple as per the package guide so all that was left to do was to take away all of the gear and get the Mustang prepared for primer and paint.

Here is the painted fuselage full with Pro-Mark markings. We used Klass Kote epoxy paint all through and have discovered it to be the easiest for warbirds.

This exhibits the dummy muffler I comprised of wooden to suit the engine and the house accessible within the engine compartment. I despatched it to J-Tec, and the corporate despatched me a functioning muffler that matched completely.

This exhibits the compact set up of the ZDZ engine, together with the difficult carb linkage. You will discover the cylinder heads have the fins positioned incorrectly (by 90 levels). I didn’t notice the error till the primary take a look at flight!

Here, we’ve got the magnificent Evolution 60cc single-cylinder engine, which made the Mustang come alive. No overheating, loads of energy, and a really neat set up, as nicely. It is an ideal engine to take the place of the trusty outdated Zenoah 62cc we’ve got been utilizing for years!

Here, we see the Shulman Aviation tailwheel unit, put in and out of the Mustang. These are simply two of the gear selections or combos you possibly can select from. I’ve actually come to like these tailwheel models. They will match a wide range of giant warbirds and although they’re electrical, they work simply the best way I like. They don’t require any extra gizmos to make them go up and down! Just plug them in, and hit the retract swap. They bolt in the identical bolt sample as an air-operated Robart tailwheel unit.

PAINT AND FINISH

Just to fortify your reminiscence, please do not forget that this isn’t a package assessment. Although, if I needed to make some feedback, I’d say that this ARF P-51 is nearly as good as something that I’ve seen so far and has good define accuracy. All parts appear to be of above common high quality, and the few “parts” you have to take care of match completely. So, getting on with my story, all the airframe was given a coat of PPG K36 mild grey primer, wet-sanded, then given a light-weight coat of Klass Kote aluminum paint. (Klass Kote, in truth, makes greater than six dozen scale Federal Standard colours for U.S. and international navy plane.)

The landing-gear mount plates are fairly strong. Grinding them to accommodate the Robart gear doesn’t weaken their integrity.

Notice that the strut lies precisely the place it’s presupposed to when retracted—a great indication that the whole lot will work as per the unique.

Landing Gear Option

There are a lot of guys on the market who’re reluctant to alter over to an all-electric touchdown gear system—and I’m one in all them. For me, it’s an set up factor. With an air-operated system, I can transfer the gear strut from as much as down at will, and might verify wheel and tire clearance and landing-gear door clearances just by activating a valve. With electrical gear, most often, you need to hook up a battery—and typically a gizmo field—and function the transmitter to activate the retract swap. Often when organising a brand new mannequin, it’d take a number of retraction cycles to get issues becoming completely. I admit it: I simply don’t have the persistence! So I go for the air-operated techniques and get on with the set up with a lot much less stress.

There is not any Hangar 9 pneumatic gear system provided with the Hangar 9 Mustang, so I contacted the gear guys over at Robart Manufacturing. After a number of minutes with CEO Dan Wenzel, it was decided that Robart was actually solely days away from releasing a set of air-operated gear for this chook however that they’d not merely drop into place. Some “modeling” work wanted to be accomplished. In avenue phrases, because of this solely those that don’t construct with a knife and fork ought to try this conversion.

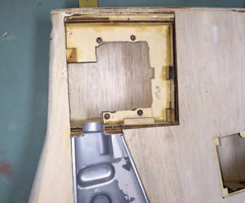

The main distinction within the retract pockets for the Hangar 9 electrical gear is that they’re only a bit too small. So within the wing, two areas have to be enlarged for the Robart air models to slide in comfortably (that means with out the usage of a hammer and chisel). In one of many photographs, you possibly can see the place I marked the landing-gear plate to point the place it needed to be trimmed. What you can’t see is that I additionally needed to considerably enlarge the outlet via which the air cylinder would move, however all of this was completed, slightly simply, with a Dremel Moto-Tool. A right-angle attachment is an actual assist on this space.

Once the gear plates had been trimmed as proven, the gear dropped in casually with just a bit ultimate massaging of the nook areas in order that the attachment holes would line up. Note right here that the blind nuts that had been already in place are 4mm. This requires the mounting holes within the Robart chassis to be drilled out respectively. I used 4 socket-head bolts to carry the Robart gear in place. The further two heart holes weren’t used. The nicest factor about this conversion is that the full time to finish it’s lower than 45 minutes. The second nicest factor about it’s that each one the landing-gear doorways match as they’re presupposed to, with no modifications. Only the hyperlinks for the strut-door connect factors want adjusting, that means that the ball hyperlinks have to be screwed in or out a bit.

I hope you discover this account fascinating, informative, and enlightening. If you had been on the fence about buying one in all these magnificent flying warbirds however discovered the electrical gear intimidating, you now don’t have any motive to withstand!

Perfection! What an ideal sense of accomplishment we felt after we retracted the struts and closed the primary wheel doorways.

Here’s the Robart air-operated fundamental gear (decrease proper), alongside a set accessible from Sierra Precision. The Shulman tailwheel is proven at prime proper, alongside a Robart unit.

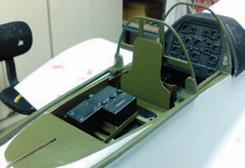

This exhibits what might be finished with the inventory Hangar 9 cockpit package and a few cans of Tamiya spray paint.

We then used Chartpak drafting tape—the 1/64-inch stuff—to make all of the panel strains. We first decided the situation of the foremost panel strains utilizing a ruler after which penciled them in place. We then laid down all of the Chartpak tape and sprayed all the airframe with a medium coat of Klass Kote aluminum paint, making use of somewhat further over the panel strains. Once cured, we utilized the trim colours and invasion stripes utilizing Klass Kote black, white, olive drab, and blue paints.

Once all of the paint had cured, we peeled off the drafting tape to disclose excellent panel strains. By this time, the paint masks and vinyl markings from Pro-Mark had arrived, so we rubbed down the end utilizing metal wool and put the markings in place. Pro-Mark makes great-looking markings and was capable of make them precisely the dimensions we would have liked. (We use Pro-Mark for the whole lot—whether or not or not it’s dry switch, Mylar, vinyl, or paint masks! If you ever deal with a paint scheme that requires particular markings, take a look at its merchandise at pro-mark.com.)

Denny insisted that the Mustang wanted to be somewhat soiled, although it was thought of to be a very-well-looked-after airplane. So I reluctantly turned it over to him and his artistic weathering abilities. I have to admit that I used to be fallacious: The delicate weathering added a ton of realism to the mannequin!

OFF WE GO!

The ZDZ 80 engine sounds unimaginable, and it has loads of energy for quick takeoffs from the grass runway.

For the primary flight, we waited for a day with mild wind, no rain, and a few sunshine. We had already accomplished a preflight inspection within the store, together with operating the engine. The ZDZ 80 has an unimaginable sound, virtually like a race motor, and I couldn’t wait to listen to it within the air. After our quick trip to the native flying discipline, we had the Mustang fueled and prepared for its first flight in lower than 10 minutes. The engine began simply, and the airplane tracked easily. There was merely no motive to not flip it into the wind and advance the throttle. Takeoff was slightly fast—I didn’t count on that form of energy! You’ve learn different accounts of how this chook performs, so I received’t bore you. It actually does the whole lot nicely, together with remarkably sluggish and smooth landings when the flaps are totally deployed. My first flight was, sadly, minimize somewhat quick. The powerhouse ZDZ 80 began making humorous noises, like when a glow motor goes too lean, and began breaking apart. Without hesitation, I acquired into the touchdown sample and accomplished a protected—and slightly good—touchdown (if I do say so myself).

Here’s the primary touchdown gear set up. It is fascinating in that it exhibits how we acquired a safer closure for these big fundamental landing-gear wheel doorways. We ran a medium-size Robart air cylinder connected to a bellcrank to get clearance away from the size Robart tires.

A SLIGHT HICCUP

It seems that the engine had overheated! I knew that I had loads of cooling space, so I used to be baffled—that’s, till we took it again to the store and one in all our store rats requested, “Why do the cylinder heads have the fins ‘going across’ instead of in line with the airflow?” Yup, are you able to think about? Not one in all us ever observed that the fins had been 90 levels off from the place they need to have been in! So we yanked out the ZDZ, and after quite a lot of work changing the entrance finish construction to the place it was earlier than the surgical procedure, we put in an Evolution 60 and wraparound muffler—very like the guide instructed within the first place!

BOTTOM LINE

We returned to the flying discipline two weeks later, and put in 4 uneventful flights. The engine carried out flawlessly—not one hiccup! This “Mustang Makeover” took little or no time. Remember, the airframe was already constructed, so all we needed to do was fiberglass it and paint it. What are the 2 issues I’ve now that I didn’t have earlier than? A extra sturdy airframe and a coloration scheme that no person else has! So on the few warbird occasions I’ve introduced it to, I’ve had enjoyable explaining that this was a Hangar 9 Mustang, not some new secret airplane being examined for anyone else! I’m guessing that of the a number of dozen who’ve seen it fly by now, eight of them have purchased one for themselves—and all of them are doing a makeover, as nicely. Who says that there are not any builders left?

TEXT & PHOTOS BY FRANK TIANO