Whether your purpose is to fly large 3D aerobatic planes or to pilot

giant-scale warbirds, understanding how gasoline engines function and tips on how to correctly set them up is extraordinarily essential. Besides their nice gasoline effectivity, gasoline engines are dependable, straightforward to start out and total are very user-friendly. Like all energy methods, nonetheless, they should be put in and arrange the best approach to preserve your airplane airborne. Let’s take a better have a look at what’s bolted to the firewall.

Getting Started

Gas engines are pretty straightforward to function. If you’ll be able to function backyard tools and chainsaws, there’s no cause you’ll be able to’t correctly arrange and run an RC gasser. Your primary gasoline engine operates utilizing the “fire triangle” principal, that means it wants air, gasoline, and warmth to run. Take any considered one of these away and it’ll not run. These three fireplace parts are introduced collectively utilizing the engine’s ignition system, carburetor, and spark plug. I like to put in a brand new engine on a take a look at stand and alter it earlier than bolting it onto my airplane. It is then a lot simpler to work out the linkages, gasoline line attachments, take a look at varied propellers and set the highest finish for max energy utilizing a tachometer.

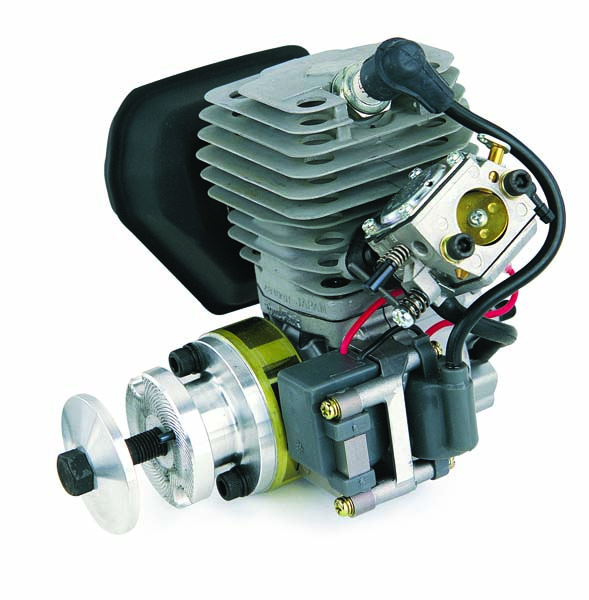

This Zenoah G45 is an older mannequin engine that makes use of a magneto setup. It’s a workhorse that requires little or no upkeep.

The new breed of smaller gasoline engines, like this RCGF Stinger 10cc side-exhaust powerplant from Legend Hobby, come outfitted with digital ignition methods.

Engine sorts

Gas engines use both a magneto spark system or an digital ignition system. Engines that use a magneto setup are just a little heavier, however very straightforward to make use of and require nearly no upkeep. There isn’t any battery required for a magneto, however you do have to put in a grounding kill swap to show the engine off and forestall it from unintentionally beginning. If you’ve gotten a helper, all the time have them fastidiously deal with your airplane and present them the place the off swap is. Newer engines with digital ignition methods are a bit lighter, however they require a separate battery pack and an influence swap to function the engine.

Always have a buddy provide help to begin your engine. Securing the mannequin’s tail prevents it from shifting ahead when the engine fires up.

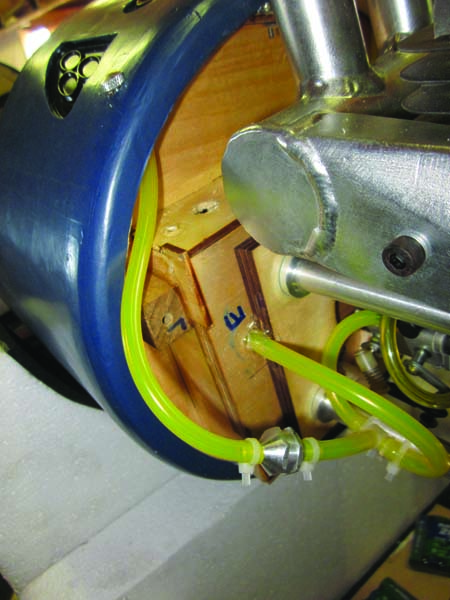

A gasoline gasoline tank with a pickup and vent line, T-fitting for the engine provide line, and a gasoline filter.

Startup

When you fireplace up your engine, the airplane can transfer ahead, so all the time have a buddy safe your airplane earlier than you begin the engine. Position the propeller blades (in relation to the magneto magnets or the digital ignition’s triggering module) because the engine handbook suggests. When you swing the propeller by compression, the spark plug ought to fireplace. If the blade place is off, it could actually make beginning the engine tougher. For elevated security, use a correct measurement electrical starter as an alternative of hand-propping the engine. But when you do hand-start it, use a glove or hen stick.

To forestall particles from clogging your engine, place filters in your gasoline container’s pickup line and between the gasoline tank and your engine.

Prop care

Always steadiness your propellers, and when you ever nostril over your airplane, verify the prop suggestions for harm. Use the dimensions and pitch really useful in your engine and test-fly utilizing that propeller earlier than attempting a unique measurement. After the primary few take a look at flights, recheck the prop bolt(s) for tightness. It is all the time a good suggestion to do that earlier than your first flight of the day.

Fuel

Regardless of your sort or measurement of gasoline engine, all the time use clear, filtered gasoline. Install a filter in your gasoline container’s pickup line in addition to between your engine and the gasoline tank. If you employ a T-fitting within the engine provide line and a gasoline dot for filling and draining your tank, place one other filter between the dot and the T-fitting.

It can also be essential to correctly combine your gasoline utilizing the engine producer’s really useful ratio for gasoline and oil. For the primary couple of tanks of gasoline, use a ratio of 30:1 to 40:1; after that, use 50:1 or regardless of the suggestion is. Some dearer artificial oils have superior safety qualities and can be utilized as much as a 100:1 combination, however I’ve solely used common 2-stroke oil out there at most backyard provide and {hardware} shops with glorious outcomes.

FAST FACT

There are 128 ounces in a gallon. For a 30:1 combine ratio, add 4.2 ounces of oil to 1 gallon of gasoline. For a 50:1 ratio, add 2.56 ounces of oil.

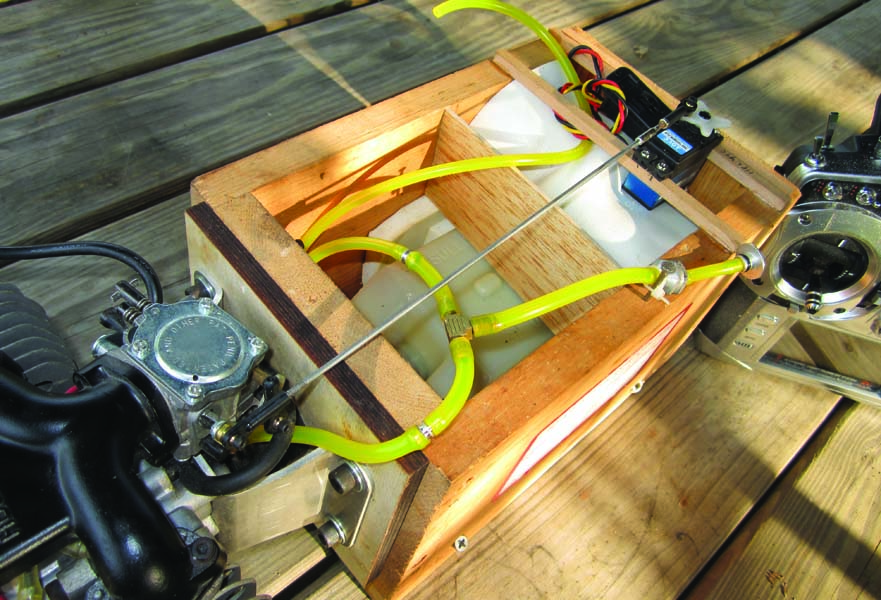

Test Rig

The finest association I’ve discovered for operating gasoline engines is an easy wooden field construction. I make the bottom from thick plywood or pine with a face (the place the engine is hooked up) that’s the identical thickness because the mannequin’s firewall. The face is supported with plywood aspect items glued and screwed collectively. I then set up the engine and screw the construction to a picnic desk. I take advantage of all the identical RC {hardware} utilized in my airplane and I set up the gasoline tank and engine ignition system contained in the field. I take advantage of a throttle servo and linkage managed with my transmitter and a receiver or an digital “servo driver” and battery to regulate the throttle. Getting to know your engine utilizing a take a look at rig is rather a lot higher than attempting to determine issues out earlier than your first flight on the flying subject.

After sorting every thing out on the take a look at rig, I then set up the engine on my airplane and take a look at run the engine as soon as extra with the engine cowl eliminated. This approach I can verify the mannequin’s linkage setup, gasoline line runs, and the tank’s plumbing for correct operate. If all of it checks out, you’ll be able to button all of it up, set up the cowl, and head to the flying subject. You’ll impress all your pals with how simply your engine fires up.

A easy, sturdy field makes an amazing take a look at rig for establishing gasoline engines. Notice the throttle servo and linkage used.

After establishing your engine on a take a look at rig, you’ll be able to set up it in your airplane and take a look at run the engine once more earlier than putting in the engine cowl.

Spark plugs come in several sizes and scores. Be positive to make use of the sort and measurement really useful by the engine’s producer.

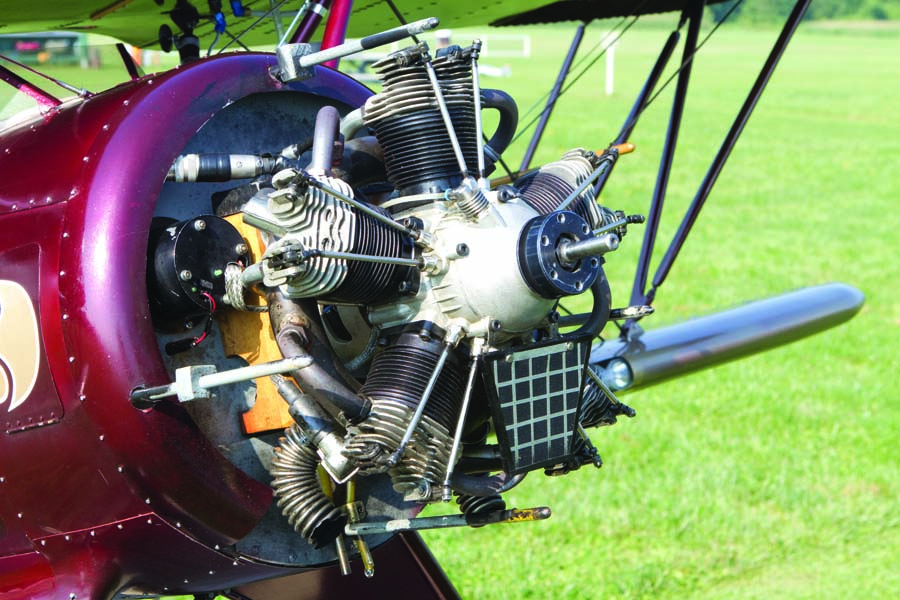

Big and spectacular multi-cylinder radial engines are very fashionable. Most are 4-strokes however they use the identical primary setups and procedures to function. Most use a single carburetor to feed the entire cylinders.

Hand-starting is the norm for many giant-scale modelers. If you do hand-prop your engine, you should definitely put on a heavy leather-based glove for elevated finger safety.

Spark Plugs

The spark plug is the center of the gasoline engine. It was essential to make use of resistor-type plugs to assist forestall radio interference that was widespread with 27 and 72MHz radios. With trendy 2.4GHz radio methods that is not a problem, however you need to use the spark plug really useful for and equipped with the engine. It can also be a good suggestion to verify to verify the spark hole is inside specs based on the directions. Should the hole be too slender or too large, it could actually have an effect on the efficiency of the engine. common setting is between 0.02 and 0.03 inch. Spark hole gauges are available at auto half shops and small engine retailers.

Needle Settings

When the engine has began, permit it to heat up a minute or two, advance the throttle slowly to full energy, and observe the response. If the engine sags, masses up and dies, it’s too wealthy. Lean the low-end needle about 1/8 flip clockwise, and check out once more. If, nonetheless, the engine makes a hole burbling sound and dies, then the combination is simply too lean. Open the needle barely counterclockwise.

Next, alter the high-end needle till the rpm peaks out and again off the needle, reducing rpm by 200 to 300. All engines unload throughout flight, so don’t attempt to get each single rev out of your engine on the bottom operating static. Once you’ve gotten the high-end needle set, verify the low-end setting once more, since adjusting both needle can have an effect on earlier setting changes you’ve made. What you’re searching for is a clean, barely delayed transition to full throttle after which stable efficiency with out the engine overheating.

Running Radials

Some of the larger RC large scale fashions at the moment are being powered by large 4-stroke, multi-cylinder radial engines. These spherical engines are very fashionable however are additionally affected by engine temperatures. With enclosed engine cowlings, it’s advisable so as to add baffles between the cylinders to channel the incoming airflow directed by the cylinders’ cooling fins. This setup lets you preserve the really useful rule of utilizing “two times the cooling air exit area relative to the air inlet area.” It is a small element however essential for a correctly operating engine. In operation, use the beginning procedures (and the gasoline combine ratio) really useful by the producer.

Bottom line

Gasoline engines, if correctly put in and brought care of, are essentially the most user-friendly energy methods out there. They are straightforward to start out, gasoline environment friendly, and dependable. After you’ve arrange your carburetor, you normally gained’t should readjust it for a complete flying season. And bear in mind it’s no secret: a correctly operating engine will drastically prolong your RC airplane’s lifespan!

TROUBLESHOOTING CHECK LIST

If you’ve gotten problem beginning and acquiring a clean transition from idle to full energy, listed below are some widespread gadgets to verify off your troubleshooting listing.

– Does your engine fireplace up, burn off the prime after which die?

Check your gasoline draw. Make positive the gasoline traces usually are not pinched, kinked, blocked or have any pinholes. Make positive your engine is correctly arrange. Is your gasoline tank put in upside-down? It occurs to the most effective of us. When you flip the prop (with the choke closed), the carburetor ought to draw gasoline and you need to be capable of see it transfer within the gasoline traces towards the carburetor.

– The carburetor doesn’t draw gasoline.

Check the needle valves for correct settings. Make positive the carburetor is tightly mounted to the engine and isn’t leaking air. Check the carburetor’s inside gasoline consumption display filter and ensure it’s clear. It is below the carburetor’s prime cap (the one held in place with a single screw). If it’s soiled, take away it and flush it with contemporary gasoline or exchange it. Finally, verify that the engine head/cylinder case is tightly mounted to the engine case and that the gasket is undamaged. Even a small air leak right here can have an effect on compression and forestall the engine from beginning.

– There’s no spark.

Make positive your kill (grounding) swap is within the right (run) place. If you’re utilizing an digital ignition, make sure that the battery is absolutely charged and the wiring to the timing sensor is correctly related.

– An engine that has been operating properly loses compression.

Check for a caught or damaged piston ring. If this occurs throughout flight, carry out an emergency touchdown as quickly as you’ll be able to. Don’t flip the engine over by hand as this could simply rating or gouge the piston sleeve. Carefully verify for inside harm. If you don’t really feel comfy doing it your self, ship the engine out for inspection and restore.

By Gerry Yarrish