When you construct a scale RC mannequin airplane, everybody needs to have a look inside your mannequin’s cockpit. Yet most informal modelers neglect this space, considering it’s an excessive amount of work or they don’t have the talents. This article will present how I am going about constructing a scale cockpit in a approach that makes all the size bits accessible. Making a cockpit look extra real looking elevates the size mannequin’s complete look, and if all of the cockpit objects are simply accessible that makes servicing your mannequin extra handy. For this text, I might be including cockpit particulars to my 1/5-scale P-51A Mustang that I constructed from Jerry Bates plans.

Building and putting in an in depth cockpit inside in your scale mannequin is a job through which you’re employed on a number of small objects and produce them collectively to finish the challenge.

THE SCALE ILLUSION

Before digging into the constructing of cockpits, let me make clear just a few issues. The first and most vital factor to recollect is to have enjoyable. This is a pastime, and everybody experiences it otherwise. If you wish to go hog-wild and replicate your mannequin’s full-scale cockpit, together with each wire, hydraulic line, and former, then go for it. On the opposite hand, for those who’d quite add only some objects, then by all means try this. The level right here is that there isn’t a legislation saying how a lot element should be added to a cockpit. When it involves scale competitors, the inside cockpit particulars aren’t even scored. The particulars are in there since you wish to embrace them. Anything from an entire museum-quality remedy to only the naked bones is as much as you.

My buddy and scale guru Dave Platt says, “Building a cockpit is more about creating the illusion of a cockpit than getting it 100 percent right.” What meaning is that typically scale modelers must take liberties as a result of we’d not have the required pictures and documentation that present the whole lot within the pilot’s most important workplace. There is so much occurring contained in the cockpit, so you will need to embrace sufficient element in order that it rewards the eye.

SAVING WEIGHT

Detail doesn’t must be heavy. One factor I hear from different builders is that together with all these scale particulars provides a variety of weight. This could be true, however with a bit of thought and energy, you may minimize down on weight acquire by being conscientious whereas deciding on supplies. Being considerate of the burden of each merchandise you add to your mannequin ought to develop into second nature for those who want to enhance your abilities as a scale modeler and can preserve your mannequin from turning right into a heavy hangar queen.

REMOVABLE COCKPIT FLOOR

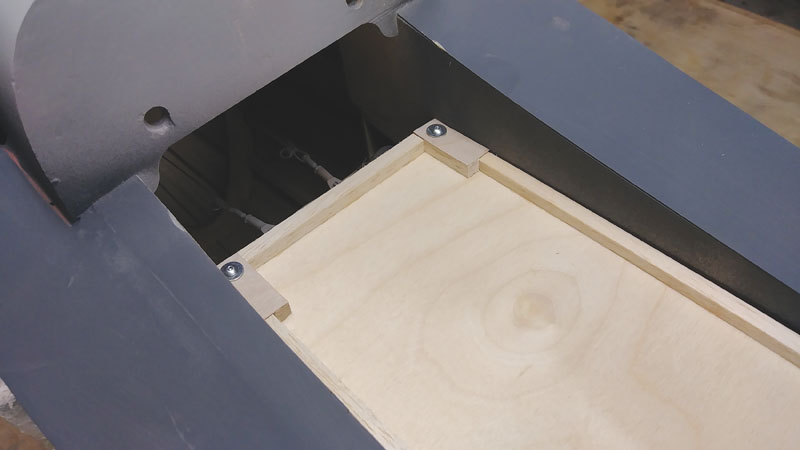

The first step is to make the cockpit ground detachable. As will probably be the muse for the remainder of the method, we wish to get it proper. The ground pictured right here is made out of 1/8-inch gentle ply and medium balsa, with 1/4-inch-square balsa sticks to offer it some rigidity. I added two small hardwood blocks within the rear corners for the attachment screws. To preserve the burden down, I restricted the size of the ground and selected the wooden rigorously.

Every mannequin is completely different, so you might want to work out the way you wish to mount the ground. For this instance, I measured the width and size of the realm I wished the ground to cowl. I minimize the ground to measurement in order that it was as shut as potential to the perimeters; that approach, if folks look inside, they gained’t see the highest of the wing. I used two 1/4-inch-square items of spruce up entrance to create a “notch” for the entrance fringe of the ground to slip into. After leveling and measuring rigorously, I glued the aft hardwood blocks in place in order that the cockpit ground may very well be screwed into place. I drilled the holes within the ground barely smaller than the screws in order that the screws would match and keep in place. I eliminated the ground and gave it a skinny coat of Zap ending resin. When dry, I sanded it clean and primed it for a end prepared to color.

The first step is to construct a light-weight ground part on which the whole lot else might be supported.

The aft part is secured with screws in order that, if wanted, the whole meeting could be eliminated by means of the wing-saddle opening beneath.

BUILDING THE COCKPIT

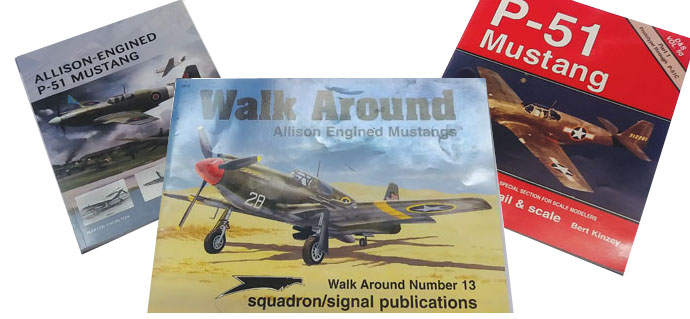

It is vital to have good reference materials to make use of as a information. I often use a mix of books, scale plastic fashions, and pictures to assist make my fashions as correct as potential.

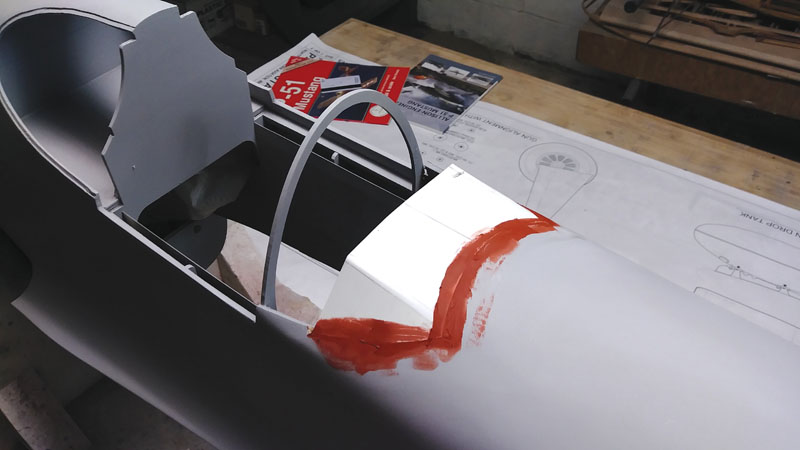

Once I adjusted the ground, I tackled the instrument-panel hood. The subject right here is that you need to go from a rounded fuselage form to a few flat panels that defend the pilot’s instrument panel. I used stiff paper inventory (you could possibly use cardboard) to mock up a dummy hood to get the form near what I wanted. Using some 1/16-inch- (1.6mm-) thick plastic, I minimize the plastic hood to form after which used a warmth gun (set on low temperature) to bend it to form. Using a Moto-Tool and a effective grinding bit, I minimize a ledge to simply accept the hood and provides it gluing floor whereas mixing the hood into the fuselage. If you should not have a Moto-Tool, you may type the ledge by gluing sandpaper to scrap wooden formed into an upside-down L and slowly sand the ledge alongside the perimeters to simply accept the hood.

I used some thick CA to connect the hood and clamp it in place. Once the whole lot was the place I wished it, use some CA kicker to start out the bonding course of. For the ultimate mixing, I used some Bondo lacquer glazing putty to fill within the areas and seams; it’s vital to clean the whole lot out in order that there’s a gradual transition between the fuselage and the hood. After the putty dried, I sanded it clean, then primed and painted it.

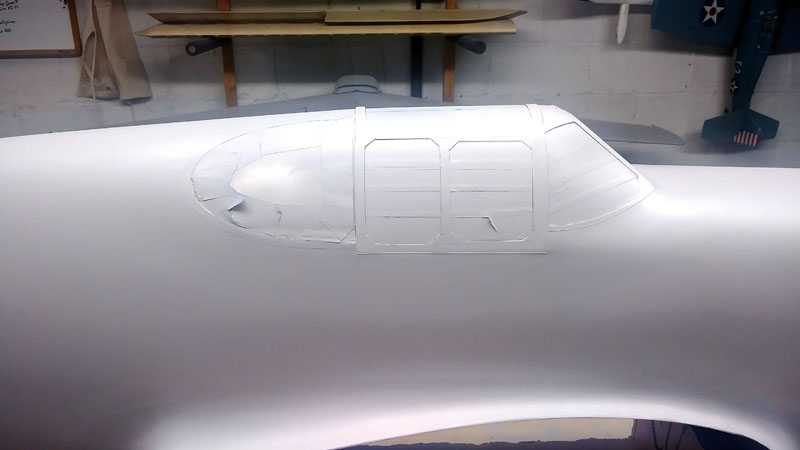

An vital a part of the cockpit space is the hood that shades the instrument panel. It is shaped with a stiff paper template after which shaped by reducing and bending

Once the hood is shaped and glued into place, it’s then feathered with putty to mix into the highest of the fuselage.

The hood is mixed into place and is primed. It will later be painted black to match the documentation pictures.

SIDEWALLS

Using 0.010 fiberglass sheet materials (out there from franktiano.com), I minimize the perimeters to form and used balsa (completed with epoxy resin) to type the highest cockpit ledges. To make all of it come collectively, I glued the perimeters into place and feathered them in alongside the ledges with lacquer putty. I masked off the fuselage across the cockpit, primed the whole lot once more, and painted the cockpit inside with Testors Model Master Interior Green Enamel.

The sidewalls for the cockpit are shaped out of clean G-10 fiberglass sheet minimize to form. The higher ledge is made out of strips of balsa glued collectively.

Once put in and painted, the sidewalls type the help for all of the little detailed bits and supply a clear backdrop. The aft a part of the cockpit is the radio compartment.

THE LITTLE BITS

While the cockpit paint is drying is an effective time to get all of the cockpit bits and items so as. There are two primary areas within the P-51A to concern ourselves with: the cockpit inside itself and the radio compartment behind the cockpit.

For the cockpit inside, I used the P-51D cockpit equipment and instrument panel from iflytailies.com. Although nearly all of the elements within the kits are supposed for the D-model, I may use them in my P-51A. As you may see, these components are resin-cast and must be assembled and painted. I used medium CA to assemble them after which painted them with Model Master flat enamels, utilized utilizing a effective brush. These kits allowed me to change varied components as wanted to get them nearer to what was wanted for a P-51A cockpit. One tip right here: Glue a small piece of plastic tubing or an previous piece of pushrod on the again of the objects whereas assembling the elements. This offers you a straightforward option to maintain the components whereas engaged on them and portray them. As you may see from the pictures, I used a block of froth to help them whereas working.

I additionally assembled the instrument panel from an iflytailies.com equipment. This work is pretty simple, and I might advocate the corporate’s cockpit element and instrument kits to anybody constructing scale fashions as they’ll prevent a variety of time.

For the radio elements, I constructed a grasp plug for every of the radio models. I then made two-part latex molds and forged the ultimate components utilizing two-part resin; the latex molds are straightforward to make and can produce a number of castings earlier than they put on out. After eradicating the forged radios from the molds and punctiliously cleansing them up, I floor out the bottoms with a Moto-Tool to take away some undesirable weight. I completed the radios with Testors Model Master Flat Black Enamel.

The radio help shelf was made merely out of balsa that I completed with a 0.5-oz. fiberglass fabric. The radio mounts are made out of sheets of styrene plastic and varied Plastruct items from the pastime store. The wire bundles have been made out of 36-gauge wire, which I stretched between two nails, wrapped with tape, and minimize to size. Once minimize to size, they have been additionally painted flat again after which hooked up to the radio models.

The greatest option to element any cockpit inside is through the use of shaped half kits. This will save a ton of effort and time in your half.

I additionally used a equipment for the instrument panel. Although this one is for a D-model Mustang, it really works properly for my A-model challenge.

ADDING REALISM

The weathering of the cockpit compartment and all its elements is vital and is a two-step course of. First, I utilized Rub ’n Buff (out there from craft shops) utilizing small brushes, bamboo skewers, and my fingers; this produces areas the place it appears to be like as if the paint has been worn off, exposing the silver steel beneath. Second, I utilized a wash of soiled brown/pink to the whole lot. The wash is made out of thinned water-based acrylic paint. This will get into all of the recesses and seams, and provides depth to the size bits and items. Once the whole lot is dry, I sprayed on some Testors Dead Flat clearcoat to offer the whole lot a good sheen; this additionally locks the weathering in. I then put in and glued the radio racks into place.

Take your time, and don’t rush the job. That approach, you’ll find yourself with neat {and professional} outcomes. (Note that the gunsight proven right here can also be constructed from a cast-resin equipment.)

To add element to the aft radio compartment, I made a grasp plug and shaped two-part rubber molds and resin-cast the ultimate radio circumstances. It can be exhausting to scratch-build a number of of them and have all of them look the identical.

INSTRUMENT PANEL INSTALLATION

This is without doubt one of the examples the place I took liberties however the phantasm remains to be there. The instrument panel is rigorously glued in place on the correct distance underneath the hood. The gunsight is from iflytailies.com and likewise will get glued in place after portray and weathering it. The hood padding alongside the perimeters could be shaped from plastic tubing slip, which is then glued into place. (You may have the ability to discover molded padding from Fourmost Products both on-line or from a well-stocked pastime store.)

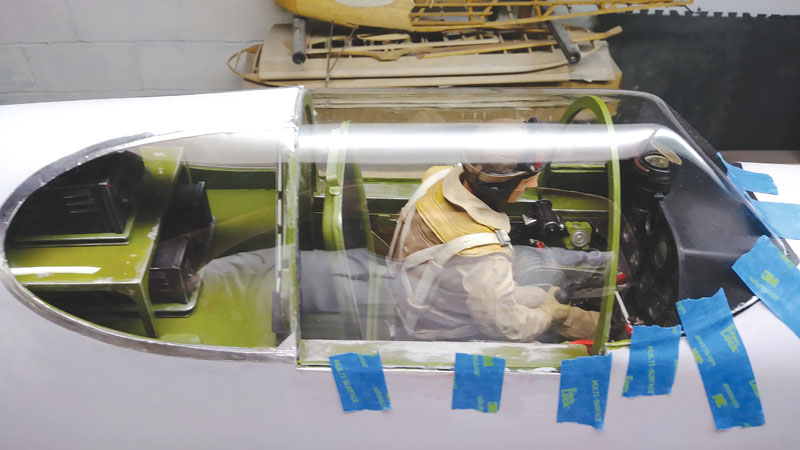

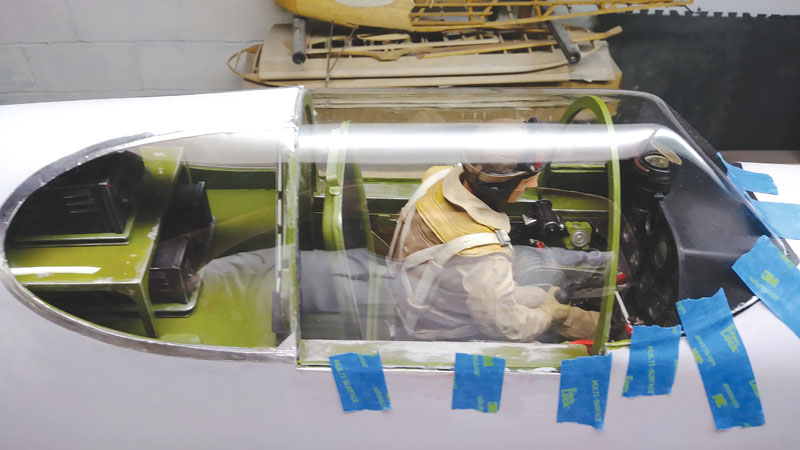

I then glued the pilot seat onto the ground after which added the pilot to the seat. My lovely scale pilot determine, which has Maj. Robert Petit’s face, is from Lyle Vasser of Best Pilots. The pilot and seat are detachable, so I can rise up into the cockpit if I have to work on it. With the whole lot now in place, we will flip our consideration to putting in the rear facet home windows in addition to the cover and cover body.

With the instrument panel and gunsight glued into place, the cockpit is admittedly beginning to take form.

Here are the completed radio-compartment items. The help rack is made out of balsa completed with resin and fiberglass fabric.

Set into place, with a bit of weathering added to focus on the floor element, the radio gear provides a lot to the look of the cockpit.

The pilot seat, the pilot determine, and all the small print are glued in place. As you may see, a lot of the detailed components are hidden by the pilot determine, however the phantasm of scale is obvious.

REAR WINDOWS

After cleansing up the mud within the radio compartment, I began gluing on the facet rear-window panels. I take advantage of Zap Formula 560 Canopy Glue to attach the clear panels into place. I used tape to strap within the panels and maintain them in place. As you could discover within the pictures, the window edges needed to be routed to permit the plastic to take a seat flush with the fuselage. After the home windows have been dry, I eliminated the protecting overlaying from the plastic. I masked off the perimeters (in addition to the whole window space) utilizing vinyl tape after which feathered them in utilizing lacquer putty. I rigorously sanded the putty and primed it to offer a clean, even edge. I added the trim and the corners utilizing some Aero Foil from Aero Accessories.

The subsequent a part of the challenge is to rigorously and neatly glue the aft home windows into place. I used Zap Formula 560 Canopy Glue for this as a result of it dries clear.

CANOPY AND FRAME

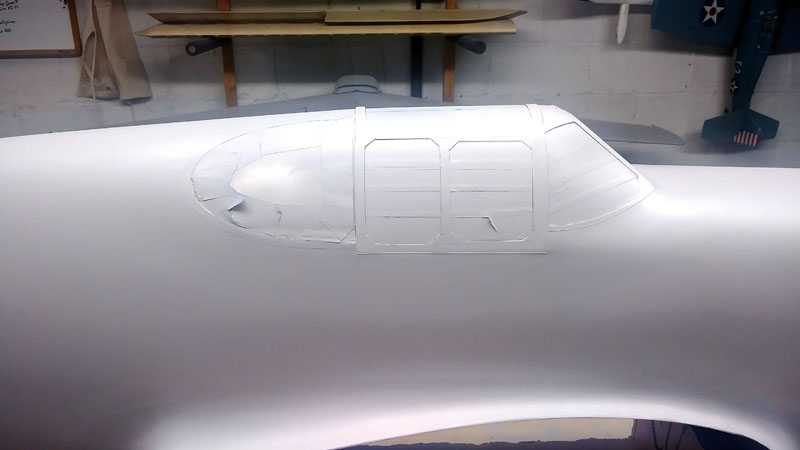

This is one space the place you might want to take your time and match, minimize, and repeat till the cover suits completely and sits flush. I once more used Zap Formula 560 Canopy Glue and ran beads across the edges. I taped the cover into place utilizing masking tape and allowed it to dry in a single day. After the cover glue had set, I glued the cover body in place over the clear cover, taping it in place till the glue dried; with Formula 560, the adhesive turns clear when dry, and you’ll clear up any extra glue with a humid paper towel. Once the cover and body have been in place on the fuselage, I feathered them in utilizing extra Bondo putty.

Once the whole lot was dry, I sanded the putty clean utilizing 320-grit paper and primed the whole space with Dupli-Color Hi-Build Primer; usually, I would depart the masking tape on till after I had painted, however I wished to take away it and present you the ultimate outcome. After I paint a mannequin, I like to make use of some plastic polish and do a ultimate cleanup of the clear plastic. Spending a bit of additional time cleansing up the perimeters after portray your mannequin will produce a scale mannequin you’ll be happy with.

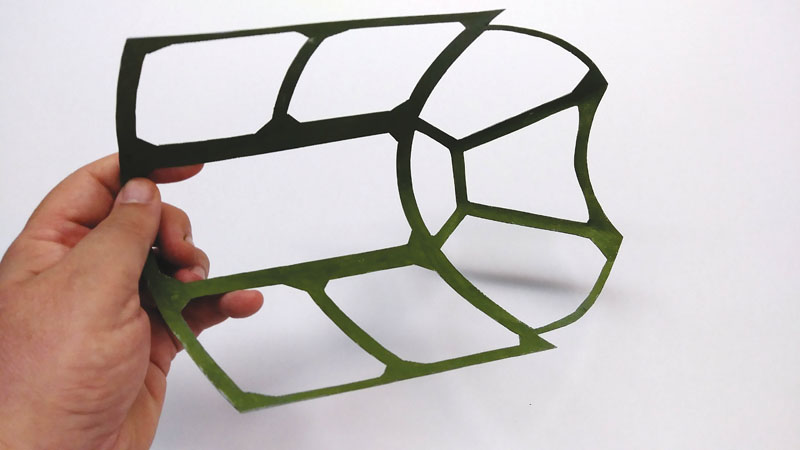

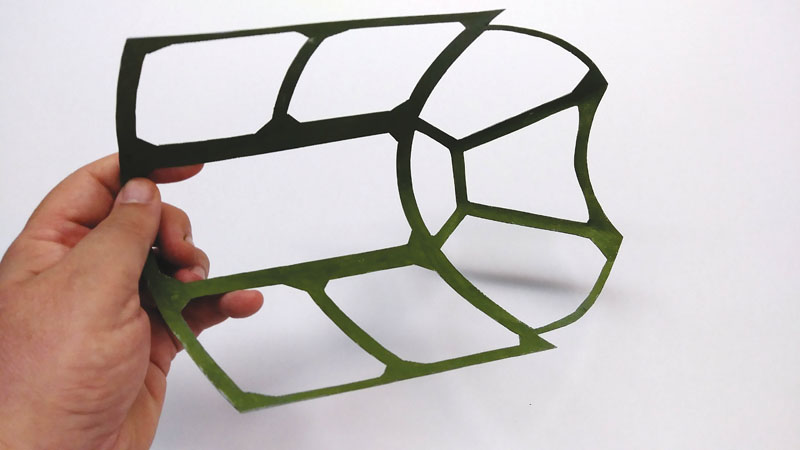

The shaped cover comes with the Jerry Bates Mustang equipment (as does the shaped cover body). Here, it’s being glued and taped into place. Again, be certain to take your time.

Here is the shaped body for the cover. I painted the interior floor with the identical inside inexperienced as the remainder of the cockpit surfaces.

After gluing the body to the cover utilizing Formula 560 glue, I let it dry in a single day after which taped off all of the clear sections in order that I might prime the framework

I additionally used a equipment for the instrument panel. Although this one is for a D-model Mustang, it really works properly for my A-model challenge.

With the masking tape eliminated, the size cockpit and cover remedy could be referred to as full. Additional cautious masking might be required whenever you apply your ultimate coat of paint to complete the mannequin.

About the Author

Mike Chilson is the founder and proprietor of rcscalebuilder.com, a web based group devoted to all features of RC scale modeling. He is an avid modeler with greater than 25 years of expertise in constructing and flying RC airplanes, and he actually enjoys his store time within the winter. During the summer time, you may often discover Mike hanging out along with his flying buddies on the native membership discipline in Birmingham, Alabama, or at fly-ins throughout the Southeast.

|

Scale Reference Books |

Text & pictures by Mike Chilson