Additive rear toe is one thing that you will see on nearly all of fashionable 1/10 touring automobiles. While in in itself it’s nothing new because it has been round for many years. It’s one thing that’s now in vougue with the newest chassis designers.

Tamiya has their very own set that’s suitable with the TRF420 and TRF420X. (And probably different chassis, however I have not checked these).

I’ve performed with this up to now with a customized hub for the sooner TRF automobiles together with my easy TT02 Rear toe information. So I believed I’d ultimately give it a attempt on my TRF420X.

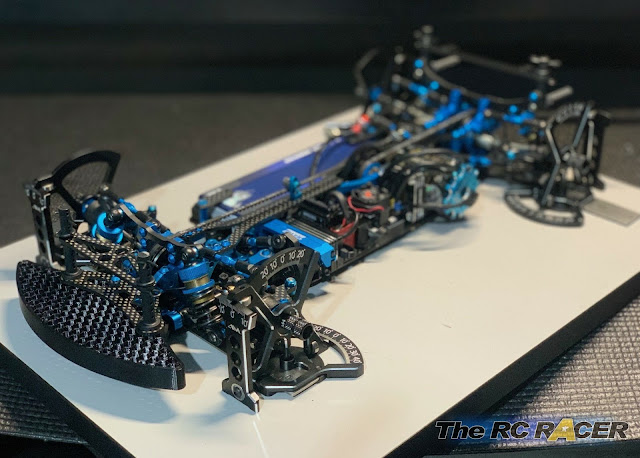

The Tamiya hop-up half comprises a number of customized half particularly for this conversion. As you’d anticipate, this ensures it is not low cost.

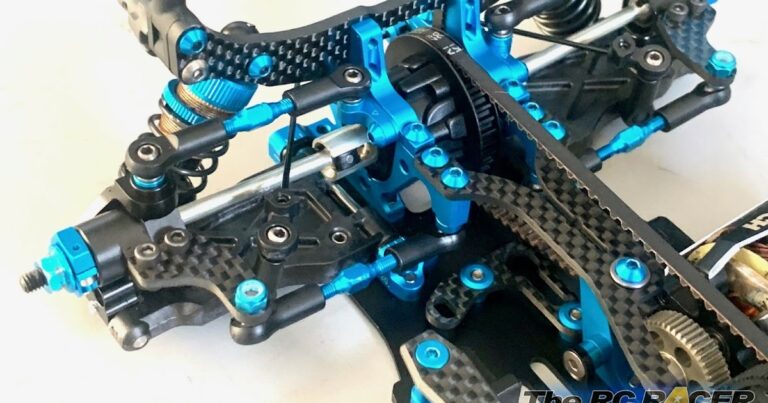

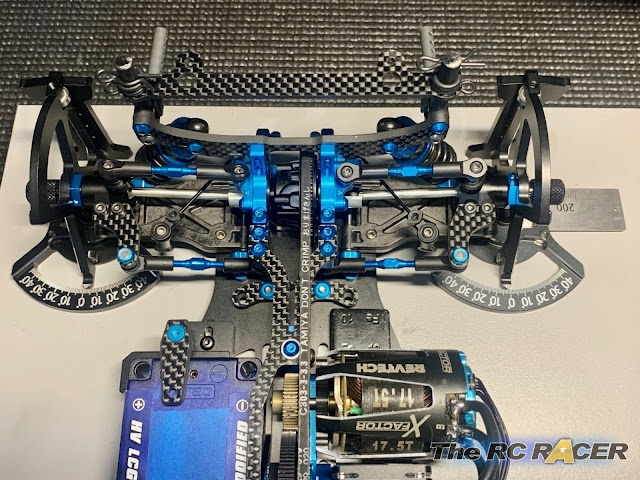

The caster blocks (C-Hubs), are produced from excessive grade, sturdy aluminium. These don’t have any caster (0deg) not like the usual entrance components (4 deg). They’re additionally distinctive as you’ve got a decrease aluminium plate that you’ll want to connect. This plate has a ball bearing that may guarantee a really clean motion of the upright as soon as it’s mounted.

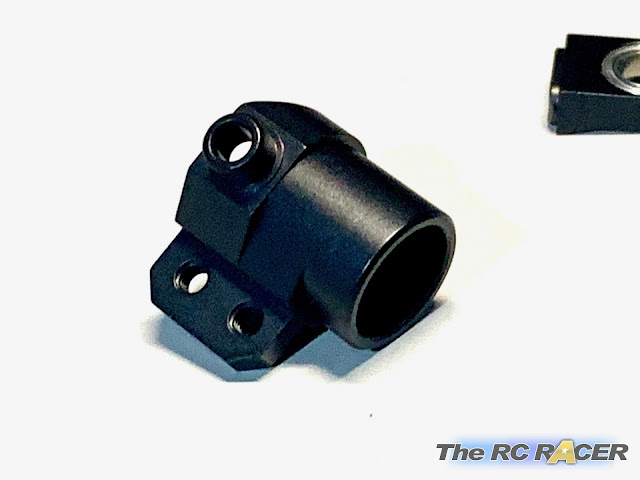

The upright is in two components, the principle hub is produced from aluminium. You may see it has a really totally different fitment to the usual upright. the higher and decrease sections have a raised nub that it’s important to mount upwards into the Caster block, and the decrease nub sits within the bearing of the decrease plate.

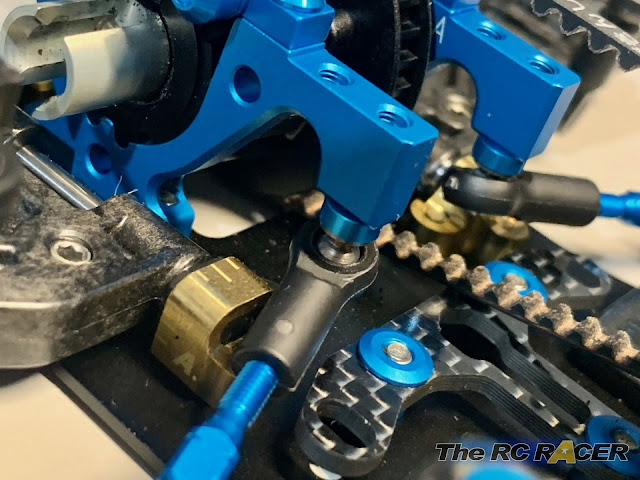

The subsequent stage of the construct was very difficult. the decrease caster plate is connected as soon as the upright is positioned (Together with some shims). It’s a must to twist it round to slip right into a recess.. this isn’t straightforward and it requires a good quantity of drive, when you do that the plate locks into place and also you add a few 2x5mm screws to firmly lock it in place. (Word I swapped out the metal hex ball connectors on this construct for the lighter Fluorine choice components).

Now it’s time to connect the upright arms. These are produced from carbon fibre and are connected with 2.6x6mm screws. This lets you modify the peak of the arm simply, that is important to simply modify the quantity of toe acquire or loss in a nook together with spacers below the arms ball connector.

The ultimate assembled half is 10.67g… chunky!

The equipment upright is 2.87g so you’re looking at an additional 15.6g of weight as soon as each rear uprights are changed. (Word it is going to be heavier in case you use the equipment metal ball connectors).

The internal hyperlinks are mounted on the underside of the rear bulkhead on the TRF420X. Within the 420X handbook it suggests you don’t match any spacers, I nonetheless added 2mm as I needed to discover a wider vary or additive toe acquire.

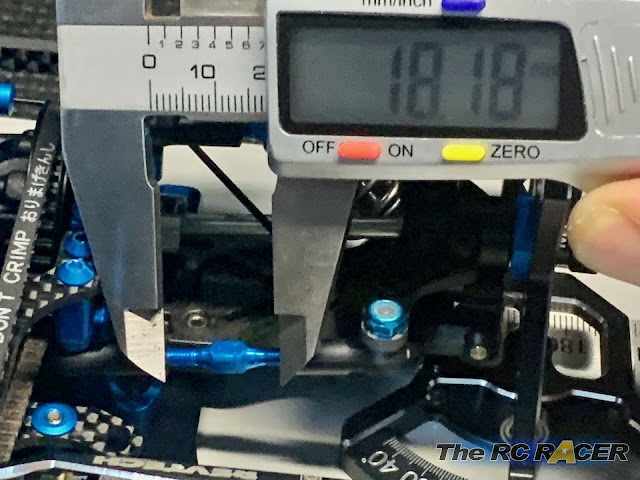

As I used to be going to run toe acquire within the nook I used to be eager to make sure that I’d profit by having no rear toe on the straights. The rear of the automotive was set to XA-C to supply 2 deg of rear toe. To attain this I needed to set the turnbuckles to 18.18mm

The rear was now set at 2 deg. Should you have a look at the angle of the internal hyperlink to the outer upright it’s excessive. This setting gave me a whopping 1.5 deg of camber acquire after I sank the chassis to the ground.

That is fairly an enormous acquire, I usually run a set quantity of two.5 deg rear toe so I do know it will present a extra locked in rear finish, however additionally it is essential to know that your automotive would not all the time floor out on a nook so the actual world acquire would most definitely be decrease.

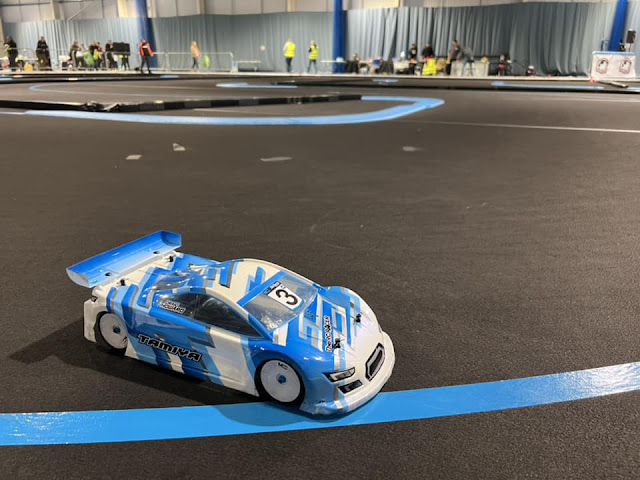

With the automotive all prepped and able to race at Micc I used to be excited to see how it will carry out.

Monitor check

The structure this time was far more technical than regular, which is one thing I favor so I used to be already excited to take the TRF420X out for a run.

Sadly observe was a little bit of a waste of time because the sensor cable was free within the automotive and it was very laggy on acceleration. The automotive appeared very planted however I used to be not going fast sufficient to know if it was factor.

After sorting the cable it was time to take out the automotive and provides it a push.. The flowing technical monitor was nice enjoyable to drive. Importantly the rear was extremely locked down regardless of how arduous I attempted to interrupt grip. The primary subject was a scarcity of steering because the rear was too sticky.

I made just a few tweaks, shifting the rear shocks outwards on the tower and going to a more durable spring. This made distinction. I had extra steering out of the nook and the rear was nonetheless locked in.

For the ultimate observe I diminished the camber angle by including a 1mm shim below the ball connector on the upright arm. This could give me much less toe acquire (Approx 1.25 deg on full compression). This labored nicely and I used to be over 8 seconds quicker within the closing qualifying session.

For the ultimate I used to be going to scale back the inboard toe to 1.5deg as a substitute of two. This could give me extra velocity on the big straight.. An excessive amount of socialising within the pits put paid to that plan, however I used to be nonetheless eager on pushing more durable within the closing as I had not discovered the sting of grip. Sadly it wasn’t to be as I used to be knocked a couple of bit and posted my worst time of the day on account of a free entrance shock tower after the collisions.

General

The additional weight is one thing that you will want to think about.. as is the value. The standard of those parts is great nonetheless. The aluminium is of the very best high quality, and after each run I checked to see if there was any motion or change within the settings. It was excellent each time.

I absolutely intend to run it once more, I’m eager to attempt combos of extreme toe acquire and low straight toe in to seek out one of the best throughout resolution.